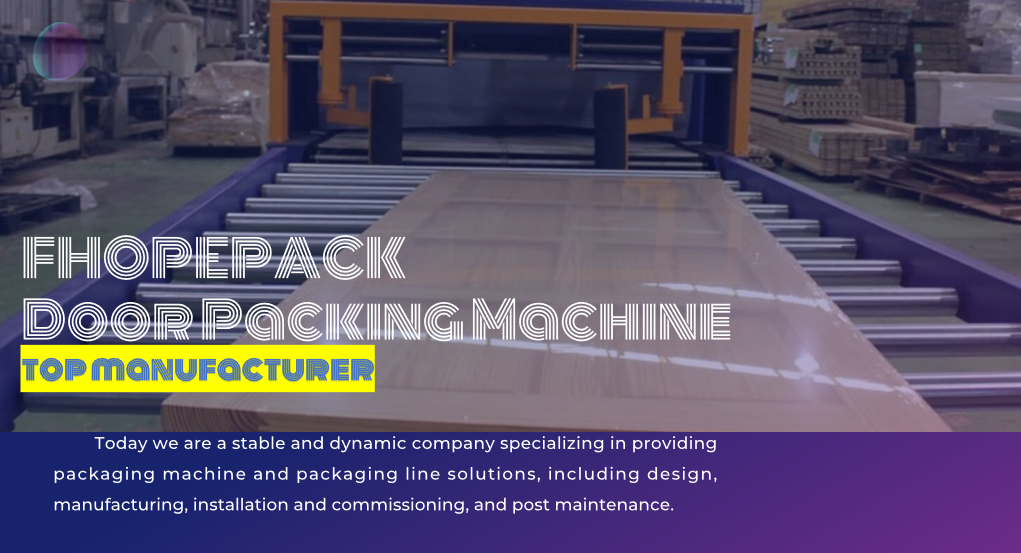

Door Packing Machine for Sale

When it comes to industrial operations, efficiency is king. Packaging processes, especially in sectors that require the careful handling of large or heavy products, demand a machine that meets quality, speed, and cost-effectiveness. For manufacturers, distributors, or production managers seeking a solution that minimizes downtime and optimizes workflows, a door packing machine can be a game-changer.

In recent years, door packing machines have evolved beyond simple automation. They now incorporate advanced materials, intelligent controls, and customizable features that can adapt to different business needs. Whether you handle wooden, steel, or glass doors, having the right packing equipment ensures product protection and streamlines operations.

This article explores everything you need to know about door packing machines, from their benefits and features to how to choose the right one for your business. Along the way, we’ll uncover essential insights to help you make an informed decision.

[Claim]: A door packing machine for sale offers businesses a versatile and efficient way to protect their products while saving on labor and operational costs.

1. What Makes a Door Packing Machine Worth the Investment?

Benefits of Door Packing Machines

In high-production environments, manual packaging of heavy or delicate doors is both time-consuming and inefficient. A door packing machine automates the process, ensuring consistent quality and reducing the risk of human error. The benefits include improved packaging speed, enhanced product protection, and significant labor savings. These machines eliminate repetitive tasks, allowing your workforce to focus on other areas of production.

Furthermore, by tightly wrapping doors with protective materials such as stretch film or bubble wrap, the machines ensure durability during transportation and storage. This reduces product damage rates and customer complaints.

Key Features to Consider

When selecting a door packing machine, the features directly impact performance and versatility. Key considerations include:

-

Machine Type: Horizontal wrapping, vertical wrapping, or fully automated models.

-

Material Compatibility: Ability to handle stretch film, bubble wrap, and foam sheets.

-

Speed and Throughput: Output capacity (e.g., doors per minute).

-

Automation Level: Semi-automatic vs. fully automatic with programmable controls.

-

Safety Mechanisms: Emergency stop features, overload protection, and sensors.

|

Feature

|

Horizontal Machine

|

Vertical Machine

|

Fully Automated

|

|

Speed (doors/minute)

|

5–10

|

3–8

|

10–15

|

|

Material Versatility

|

High

|

Medium

|

Very High

|

|

Labor Dependency

|

Moderate

|

High

|

Low

|

|

Safety Enhancements

|

Standard

|

Basic

|

Advanced

|

Understanding the machine's features ensures you choose one tailored to your operational needs.

Performance and Speed Comparison

Speed and performance directly influence ROI when investing in packaging equipment. For instance, semi-automatic machines may handle up to 5 doors per minute, whereas fully automated machines can exceed 10–15 doors per minute depending on configuration.

A performance comparison allows businesses to weigh the trade-offs:

-

Semi-automatic machines are ideal for lower production rates and budget-conscious buyers.

-

Fully automated models excel in high-volume operations, reducing packaging costs per unit.

By balancing performance with cost, businesses can optimize efficiency without overspending.

Customization Options for Different Door Types

Not all doors are created equal, and neither are door packing machines. Modern machines offer customizable settings that allow businesses to adapt to different door types, such as:

-

Wooden Doors: Require protection against scratches and moisture.

-

Steel Doors: Benefit from heavy-duty wraps and corrosion-resistant materials.

-

Glass Doors: Need extra cushioning and protective foam layers.

Advanced machines allow you to adjust parameters like film tension, wrapping layers, and speed to accommodate varying door dimensions and materials. Such versatility ensures maximum protection and cost efficiency.

|

Door Type

|

Key Requirements

|

Customizable Solutions

|

|

Wooden Doors

|

Anti-scratch, moisture

|

Stretch film + foam padding

|

|

Steel Doors

|

Corrosion resistance

|

Heavy-duty wrap, multi-layered

|

|

Glass Doors

|

Shock absorption

|

Bubble wrap, protective sheets

|

By choosing a machine with adaptable features, you can meet diverse production demands without needing multiple systems.

Fact Check: Which Claim is Accurate?

-

A door packing machine can reduce labor costs by 40–60%.

True: By automating repetitive tasks, businesses save on manual labor and reallocate resources to other operations.

-

Manual packaging is faster than automated packaging systems.

False: Automated machines significantly outpace manual methods, especially in high-production environments.

Automating your packaging line not only speeds up workflows but also minimizes waste and human errors.

2. How Can You Choose the Best Door Packing Machine for Your Business?

Factors That Influence Machine Selection

Choosing the right door packing machine involves assessing your production goals, budget, and operational environment. Key factors to evaluate include:

-

Production Volume: High-volume facilities benefit from fully automated systems, whereas smaller operations may find semi-automatic machines sufficient.

-

Door Specifications: Consider the dimensions, weight, and material of the doors your facility handles. Machines with adjustable parameters are essential for versatility.

-

Space Availability: Ensure the machine fits within your production line without creating bottlenecks. Compact models are available for space-restricted facilities.

-

Future Scalability: Opt for a machine that can adapt to higher production demands as your business grows.

-

Maintenance Requirements: Machines with user-friendly designs and low-maintenance components minimize downtime and long-term costs.

By aligning these factors with your business goals, you can make an informed investment that enhances efficiency.

Pricing and Cost Analysis

The cost of door packing machines varies widely based on features, automation level, and brand reputation. Below is a cost comparison to give you a clearer picture:

|

Machine Type

|

Average Price Range

|

Features Included

|

Suitable For

|

|

Semi-Automatic

|

$8,000–$15,000

|

Basic wrapping functions

|

Small to medium operations

|

|

Fully Automatic

|

$20,000–$50,000+

|

High-speed, intelligent controls

|

High-volume operations

|

|

Customized Solutions

|

$50,000+

|

Tailored wrapping configurations

|

Specialized production lines

|

While the upfront cost may seem significant, fully automated machines deliver substantial savings in labor and increased throughput. A well-calculated ROI ensures the investment pays for itself over time.

Pros and Cons of Automated Door Packaging

|

Pros

|

Cons

|

|

Significant labor cost savings

|

High initial investment

|

|

Consistent and high-quality packaging

|

Requires skilled operators for setup

|

|

Enhanced production speed

|

Maintenance costs

|

|

Adaptability for multiple door types

|

Space considerations in small plants

|

Businesses must balance these trade-offs to determine the best-fit solution for their unique needs.

Real-World Applications and Case Studies

Many manufacturers have transformed their packaging operations with door packing machines. Let’s explore two real-world examples:

-

Case Study 1: Wooden Door Manufacturer

A medium-sized wooden door manufacturer implemented a semi-automatic door packing machine to improve packaging consistency and reduce manual labor. After six months, they reported:

-

40% reduction in labor costs

-

30% improvement in production efficiency

-

Significant reduction in product damages during shipping

-

Case Study 2: Steel Door Production Plant

A large-scale steel door manufacturer switched to a fully automated door packing machine capable of wrapping 12 doors per minute. The results:

-

Production output doubled

-

98% reduction in packaging defects

-

High ROI achieved within 12 months

These case studies highlight how businesses of different scales can benefit from tailored solutions.

Fact Check: True or False Statements

-

Door packing machines require no operator involvement.

False: While automated machines reduce manual effort, they still require supervision and maintenance by skilled operators.

-

Fully automated door packing machines can achieve wrapping speeds of up to 15 doors per minute.

True: High-performance models can reach impressive speeds, significantly enhancing throughput in large production facilities.

By understanding these facts, businesses can set realistic expectations when upgrading to automated systems.

3. What Are the Latest Innovations in Door Packing Machines?

Smart Automation Technologies

The integration of smart automation technologies is revolutionizing door packing machines. Features such as programmable logic controllers (PLCs), IoT-enabled sensors, and touch-screen interfaces allow operators to monitor and control processes with precision. Smart automation reduces human intervention while enhancing consistency in packaging.

Additionally, machines now incorporate advanced AI-driven quality control systems that identify issues like loose wraps, misalignments, or film wastage. This ensures that each door meets strict packaging standards, saving time and reducing rework costs.

Smart technology also enables predictive maintenance, where sensors monitor machine health and flag potential breakdowns before they occur. This minimizes unexpected downtime, improving overall productivity.

Materials and Sustainability Trends

Sustainability is becoming a core priority for manufacturers adopting door packing machines. Modern machines now support eco-friendly packaging materials like recyclable stretch film, biodegradable wraps, and reusable foam sheets.

Below is a comparison of sustainable materials and their applications:

|

Material

|

Benefits

|

Common Applications

|

|

Recyclable Stretch Film

|

Reduces environmental impact

|

Wooden and steel doors

|

|

Biodegradable Bubble Wrap

|

Breaks down naturally in disposal

|

Glass and delicate doors

|

|

Reusable Foam Padding

|

Reduces material waste

|

High-value doors for export

|

Manufacturers who prioritize these materials not only meet environmental regulations but also appeal to eco-conscious customers.

Increased Efficiency in Modern Machines

Efficiency gains in modern door packing machines stem from faster wrapping speeds, reduced material consumption, and minimized operator workload. Machines now feature automatic film tension adjustments that optimize material usage without compromising wrap integrity.

For instance, the latest high-speed models can handle up to 20 doors per minute while maintaining consistent wrap quality. These improvements translate into:

-

20% reduction in material waste

-

15–30% improvement in production speed

-

40% decrease in operational costs

By investing in newer models, manufacturers can achieve higher throughput without increasing overhead costs.

Understanding ROI from Innovations

Return on investment (ROI) is a key consideration when adopting innovative technologies. While high-speed, automated machines require a larger upfront investment, the long-term savings are substantial.

A typical ROI calculation for a fully automated door packing machine:

|

Investment

|

Cost Savings (Annual)

|

Payback Period

|

|

$40,000 (Machine Cost)

|

$18,000 (Labor Savings)

|

2–2.5 Years

|

By factoring in savings from labor, reduced material usage, and increased production output, manufacturers can justify the adoption of innovative machines.

Fact Check: Two Key Insights to Verify

-

AI-enabled door packing machines can detect wrap inconsistencies in real time.

True: Modern systems use sensors and AI algorithms to identify and correct errors during operation.

-

Eco-friendly packaging materials are more expensive than traditional materials.

False: While initial costs may be slightly higher, reduced environmental fees and improved customer appeal often offset the difference over time.

These innovations ensure that businesses stay competitive, efficient, and environmentally responsible.

4. How Can Door Packing Machines Improve Long-Term Business Outcomes?

Reducing Labor Dependency

One of the most significant advantages of door packing machines is the reduction of manual labor dependency. By automating repetitive and labor-intensive tasks, businesses can achieve higher operational efficiency while reducing human error.

For instance, a fully automated machine can wrap 15–20 doors per minute, a task that would otherwise require a team of workers over a much longer timeframe. This not only lowers labor costs but also frees up skilled staff for tasks that add more value to the production process.

Labor shortages and rising wages make automation a strategic investment. Businesses can scale production without worrying about workforce constraints or inconsistency in quality.

Enhancing Product Safety During Shipping

A key concern for manufacturers is ensuring doors arrive at their destination free of damage. Door packing machines solve this issue by applying uniform layers of protective materials that secure doors against scratches, moisture, and impact damage.

For example:

-

Glass doors benefit from multi-layered bubble wrap.

-

Steel doors require corrosion-resistant wraps to prevent oxidation.

-

Wooden doors are protected using foam sheets to avoid dents and surface damage.

Machines with customizable wrapping programs ensure every door type receives the right level of protection, reducing product returns and increasing customer satisfaction.

Streamlining Maintenance and Durability

Modern door packing machines are built for durability, featuring robust components and user-friendly designs that simplify maintenance. Key features like self-diagnostic tools and predictive maintenance systems allow operators to identify and resolve issues proactively.

Regular maintenance schedules and easy access to spare parts further extend the machine’s lifespan. Below is a durability comparison:

|

Machine Type

|

Maintenance Frequency

|

Average Lifespan

|

|

Semi-Automatic

|

Monthly

|

8–10 Years

|

|

Fully Automated

|

Quarterly

|

12–15 Years

|

By investing in machines with long-term durability, businesses avoid costly breakdowns and replacements.

Cost-Saving Strategies for Future Growth

A well-implemented door packing machine offers multiple cost-saving benefits that support long-term business growth:

-

Material Optimization: Automatic tension control reduces material waste by 20–30%.

-

Lower Labor Costs: Automation replaces multiple manual workers, saving up to 40% annually on labor expenses.

-

Reduced Downtime: Predictive maintenance minimizes unplanned stoppages, ensuring consistent production.

Over time, these savings significantly improve profit margins, allowing businesses to reinvest in other areas of growth, such as expanding product lines or upgrading facilities.

Conclusion

A door packing machine is more than just an investment in packaging—it’s an investment in efficiency, safety, and long-term growth. By automating the wrapping process, businesses can reduce labor costs, optimize material usage, and improve product safety, all while enhancing production capacity.

Whether you operate a small-scale facility or a large manufacturing plant, choosing the right machine tailored to your needs ensures a higher return on investment and keeps your business competitive in the market.

[Claim]: Door packing machines revolutionize packaging operations by reducing costs, increasing efficiency, and enhancing product safety—making them a cornerstone for future-ready businesses.