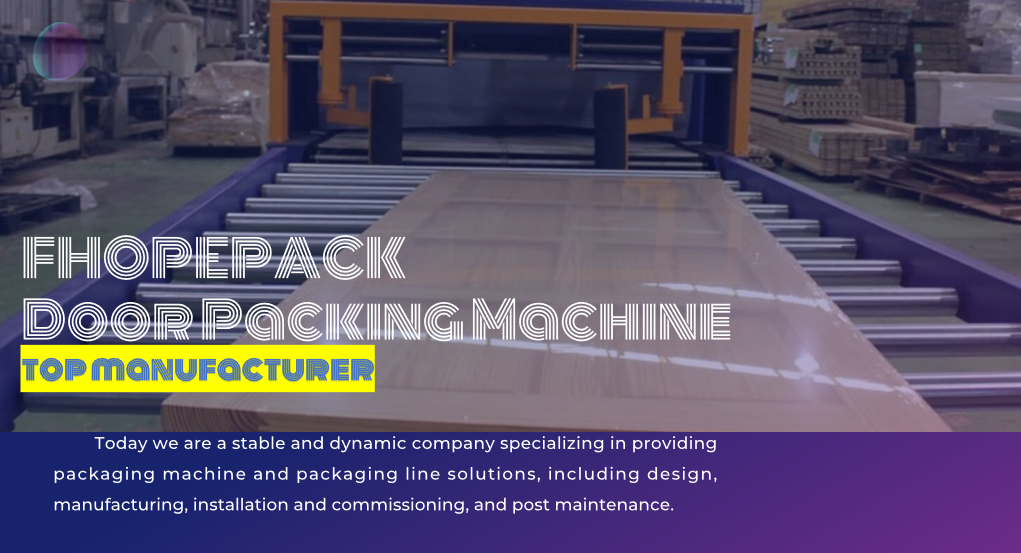

Door Packing Machine Manufacturer

In the competitive landscape of modern manufacturing, door packing machines have become indispensable tools for improving efficiency and safeguarding products. Whether you're producing wooden, steel, or aluminum doors, choosing the right packing equipment determines not only the safety of your products but also your company's operational success.

Manufacturers today face unique challenges: labor costs are rising, customer demands are shifting, and ensuring packaging compliance has never been more crucial. For businesses, the door-packing process must be streamlined, precise, and reliable. That’s why selecting a professional door-packing machine manufacturer can mean the difference between costly downtimes and flawless productivity.

As someone who has closely evaluated the benefits of modern door-packing solutions, I can confidently say that partnering with the right manufacturer unlocks massive gains. From automation efficiency to customized packaging lines, these machines deliver results that significantly impact productivity, labor savings, and product protection.

[Claim]

The right door packing machine manufacturer doesn’t just provide equipment; they offer a complete solution that ensures superior product quality, maximum uptime, and exceptional long-term ROI.

1. What Should You Consider When Choosing a Door Packing Machine Manufacturer?

1.1 Types of Door Packing Machines Available

When choosing a door packing machine manufacturer, understanding the types of machines available is critical. Door packaging equipment varies based on the size, material, and production requirements of your doors.

-

Manual Machines: Suitable for small-scale operations, these machines require significant labor involvement but come with lower upfront costs.

-

Semi-Automatic Machines: These strike a balance between cost and automation, offering partially automated processes to reduce labor without the hefty investment of fully automated lines.

-

Fully Automatic Machines: Best for large-scale manufacturers, these machines can package hundreds of doors per hour with minimal human intervention, maximizing speed and efficiency.

Modern manufacturers also offer specialized machines for unique packaging requirements, such as shrink wrapping, corrugated box packing, or stretch film wrapping.

1.2 Key Specifications to Look for in Door Packing Machines

Selecting the right door packing machine involves evaluating critical specifications. Ignoring these aspects could lead to costly inefficiencies.

Key Parameters:

|

Specification

|

Importance

|

|

Capacity

|

Measured in doors per hour, it determines production output efficiency.

|

|

Machine Size

|

Ensures compatibility with your factory layout and door dimensions.

|

|

Material Compatibility

|

Must handle various packaging materials like shrink wrap, cardboard, or film seamlessly.

|

|

Power Consumption

|

Energy-efficient machines lower operational costs and reduce environmental impact.

|

Leading manufacturers provide tailored machines based on your exact production specifications, ensuring optimal resource utilization and performance.

1.3 How Automation Improves Packing Efficiency

Automation in door packing machines offers a transformative solution to the age-old problem of inconsistent packaging. By integrating fully automated systems, manufacturers can achieve:

-

Higher Speed: Automated machines package up to 50% more doors per hour compared to manual processes.

-

Labor Reduction: Companies save up to 40% in labor costs, reallocating skilled workers to more value-driven tasks.

-

Consistency: Machines deliver uniform wrapping quality, reducing the risk of product damage.

In addition, automated machines offer advanced features like real-time monitoring and predictive maintenance systems, ensuring minimal downtimes and better control over production.

1.4 Ensuring Material Compatibility for Packaging

Choosing the wrong packaging material can lead to damaged products, unnecessary waste, and rising costs. Therefore, it’s essential to partner with a door packing machine manufacturer who understands material compatibility.

Common Materials Used:

|

Material Type

|

Benefits

|

|

Shrink Wrap

|

Tightens around doors to protect against moisture and dust.

|

|

Stretch Film

|

Provides secure yet flexible packaging for heavy and large doors.

|

|

Corrugated Boxes

|

Offers superior impact resistance, ideal for fragile or high-value doors.

|

A quality manufacturer will ensure machines can seamlessly integrate with your preferred packaging material, reducing waste and maximizing protection.

1.5 Two Fact Statements: One True, One False

-

True: Automated door packing machines can reduce packaging time by over 50%, significantly boosting production efficiency.

-

False: Manual packing processes offer the same consistency and precision as fully automated machines.

2. Why Is After-Sales Support Critical for Door Packing Machines?

2.1 Importance of Post-Installation Support

After purchasing a door packing machine, post-installation support ensures seamless operation and optimal performance. This support extends beyond simple machine delivery, as it involves fine-tuning the equipment to meet specific production needs. Manufacturers offering robust after-sales support help companies:

-

Reduce downtime during the critical initial setup phase.

-

Optimize machine performance through personalized training and configurations.

-

Troubleshoot unexpected issues with expert guidance, saving time and resources.

Without post-installation assistance, even the most advanced packing machines can become a liability rather than an asset.

2.2 Maintenance Plans and Service Packages

Door packing machines, like all industrial equipment, require regular maintenance to operate efficiently and avoid costly breakdowns. Leading manufacturers offer tailored maintenance plans and service packages to suit production demands.

Key Components of Maintenance Plans:

|

Service Type

|

Frequency

|

Benefit

|

|

Preventive Maintenance

|

Monthly/Quarterly

|

Prevents wear and tear from escalating.

|

|

24/7 Technical Support

|

On-Demand

|

Immediate assistance minimizes downtime.

|

|

Spare Parts Availability

|

As Needed

|

Guarantees quick replacement and repairs.

|

Manufacturers that provide proactive maintenance solutions allow businesses to extend the lifespan of their machines while avoiding unexpected production halts.

2.3 Benefits of Real-Time Technical Assistance

One of the standout advantages of choosing a reliable door packing machine manufacturer is access to real-time technical support. Downtime in manufacturing facilities can lead to significant financial losses, especially in high-volume production environments.

Key Benefits of Real-Time Support:

-

Rapid Issue Resolution: Problems can be diagnosed and fixed remotely, reducing machine idle time.

-

Expert Guidance: Technicians provide step-by-step instructions for troubleshooting minor malfunctions.

-

Enhanced Productivity: With minimal disruptions, production lines continue running smoothly.

Top-tier manufacturers leverage advanced tools such as video conferencing, remote diagnostics, and IoT-enabled systems to provide efficient, real-time assistance.

2.4 Conclusion

After-sales support is the backbone of any successful machinery investment. Whether it’s through maintenance plans, technical assistance, or spare part availability, strong support ensures machines perform reliably over time. Investing in a manufacturer with excellent after-sales service translates to fewer breakdowns, higher efficiency, and long-term cost savings.

2.5 Two Fact Statements: One True, One False

-

True: Regular preventive maintenance can extend the life of a door packing machine by up to 30%.

-

False: After-sales support is only necessary during the initial installation phase and has no long-term benefits.

3. How Can Door Packing Machines Reduce Operational Costs?

3.1 Energy-Efficient Systems for Sustainable Operations

Door packing machines equipped with energy-efficient systems offer significant savings on utility costs while promoting sustainable manufacturing. Modern machines are designed to consume up to 25% less energy without compromising performance.

Energy Savings at a Glance:

|

Feature

|

Energy Reduction %

|

Impact on Costs

|

|

Smart Power Management

|

20%

|

Reduces energy waste during idle times.

|

|

Eco-Friendly Motors

|

25%

|

Optimizes power usage across operations.

|

Sustainable operations are increasingly vital for manufacturers aiming to meet global environmental standards and reduce carbon footprints.

3.2 Data-Driven Insights for Process Optimization

Modern door packing machines are equipped with data analytics systems that provide actionable insights to improve efficiency. These systems monitor key parameters such as production speed, material usage, and error rates.

Benefits of Data-Driven Systems:

-

Identify bottlenecks in the packing process.

-

Track real-time performance to minimize downtime.

-

Optimize resource utilization for maximum cost savings.

Manufacturers leveraging smart machines report a 15% improvement in productivity and significant reductions in labor-related costs.

3.3 Packaging Material Costs and Waste Reduction

Door manufacturers often face unnecessary expenses due to inefficient use of packaging materials. Modern machines incorporate advanced wrapping systems to ensure optimal material usage while maintaining product protection.

Material Efficiency Breakdown:

|

Machine Feature

|

Material Savings %

|

Benefit

|

|

Precision Wrapping Sensors

|

20%

|

Eliminates excess material usage.

|

|

Automatic Adjustments

|

15%

|

Tailors wrap tension to door size.

|

Reducing packaging waste not only lowers costs but also enhances environmental sustainability.

3.4 Custom Automation Features for Door Manufacturers

Customization plays a pivotal role in aligning door packing machines with specific business needs. Leading manufacturers offer features like variable speed controls, multi-material compatibility, and integrated safety systems.

Custom solutions allow businesses to streamline workflows, minimize errors, and meet unique packaging requirements effortlessly. The result is a dramatic improvement in overall productivity and resource optimization.

Two Fact Statements: One True, One False

-

True: Energy-efficient door packing machines can lower operational costs by up to 25%.

-

False: Custom automation features have no impact on reducing production errors.

4. What Innovative Features Should Modern Door Packing Machines Have?

4.1 Advanced Control Systems for Precision Packing

Modern door packing machines are equipped with advanced control systems that ensure accurate and consistent packing for all door types. These systems enable precise wrapping by monitoring real-time parameters such as door dimensions, material tension, and packaging speed.

Key components of advanced control systems include:

-

Programmable Logic Controllers (PLCs) for automated operation adjustments.

-

Touchscreen Interfaces that simplify machine operation for staff.

-

Adaptive Algorithms that adjust wrap settings based on product variations.

These features reduce human error, ensuring that each door is packaged efficiently and securely while maintaining consistency across the production line.

4.2 Integration of IoT in Packing Systems

The integration of Internet of Things (IoT) technology has revolutionized the functionality of door packing machines. IoT-enabled systems connect machines to centralized networks, allowing manufacturers to monitor, analyze, and improve processes in real time.

Benefits of IoT-Enabled Systems:

|

Feature

|

Advantage

|

|

Real-Time Monitoring

|

Tracks machine performance and detects anomalies.

|

|

Predictive Maintenance

|

Prevents breakdowns by analyzing machine data.

|

|

Remote Diagnostics

|

Troubleshoots problems without on-site visits.

|

Manufacturers adopting IoT see reduced downtime by up to 40%, improved productivity, and lower maintenance costs.

4.3 Quality Control Mechanisms in Door Packing

Ensuring product quality is paramount for door manufacturers, and modern packing machines incorporate built-in quality control mechanisms to meet this need. These mechanisms monitor the packaging process and detect any irregularities in wrapping tension, alignment, or material application.

Some key features include:

-

Sensor-Based Detection: Identifies misalignments and corrects them in real time.

-

Automated Rejection Systems: Removes improperly packed doors from the line.

-

Wrap Consistency Checks: Ensures uniform wrapping quality for each door.

By integrating quality control mechanisms, manufacturers reduce packaging errors, prevent product damage, and enhance customer satisfaction.

4.4 Safety Systems for Operator Protection

Modern door packing machines prioritize operator safety by incorporating state-of-the-art safety systems. These systems not only reduce the risk of workplace accidents but also ensure compliance with stringent industry regulations.

Key safety features include:

-

Emergency Stop Mechanisms that immediately halt machine operation during malfunctions.

-

Safety Light Curtains that detect operator presence near moving parts and trigger an automatic shutdown.

-

Enclosed Machinery Design to prevent access to hazardous zones.

Incorporating these safety systems minimizes risks, enhances workplace safety, and promotes a culture of reliability and trust.

Conclusion

Choosing a modern door packing machine equipped with innovative features is no longer an option but a necessity for manufacturers seeking efficiency, quality, and safety. From advanced control systems to IoT integration, these machines deliver unparalleled benefits that improve productivity, reduce costs, and ensure compliance.

[Claim]

Modern door packing machines, with their advanced features and safety systems, empower manufacturers to meet increasing production demands while ensuring operational efficiency and workplace safety.