THE WAY TO HELP COIL WRAPPING WITH PERFECT TENSION BY STRETCH FILM

Many custmer looking for one wrapping machine works for big coil size range packaging. Because of in the production, there are many size coil customized per client's requirement.

The packing machine need to be flexiable per different production plan. Especially in the steel wire production.

The traditional coil wrapping machine is not able makes the big ring wrapper for small coil wrapping. Becasue of the stretch film tension is a problem in the film application.

Now FHOPE developed an special tension controller named film drawing back device that is able keeping the good tension for big ring wrapper for small coil film wrap procession.

Regarding

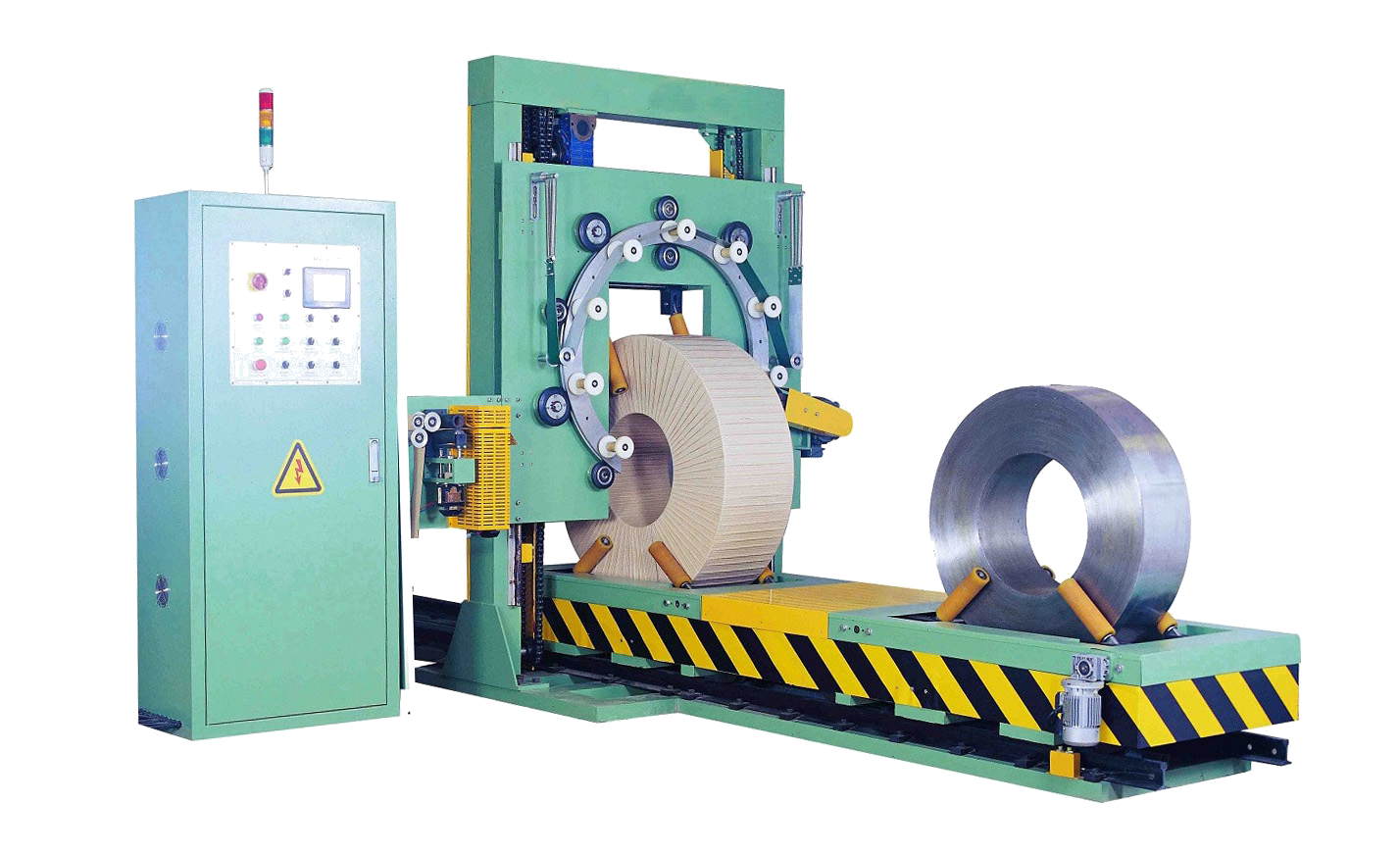

coil wrapping machine FPW-550N for you, the most important and key point is adopting a special design pull-back to increase tension control during machine running, to ensure the surface of the product packaging is tidy&neat enough. Video of Pull-Back Design:

Video of With Pull-Back Design wrapping packing for Big coil & Small coil.

---For big coil

" width="80%">

Without the special design Pull-back on machine, due to the improper tension, the packaging material is loose and the surface of the packaging is uneven and untidy,

as below shown.

Fhope team is specialized in designing and producing steel coil,

wire coil packaging machines for more than 15 years. We attach great importance to the special design and customization of machines to ensure the high quality of machines and packaging effects.

Technical Parameters of FPW-550N:

Object material: Galvanized Iron wire coil

Coil Height(W): 300-550 mm

Coil outer diameter(OD): 350-600mm

Coil inner diameter(ID): 300-350mmm

Coil weight:80-800kg(max)

Packing material: PE stretch film (fix on the ring)

ID:50mm OD:120mm Width:100mm

Ring speed: 20- 50r/min

Overlap rate:20%~90%

Power :app. 8.5Kw

Power supply:380V,60Hz, Three-phase five line

Air supply:6~8kgf/cm

2

Machine size: L4500mm x W2500mm

Machine weight: App.3.0 tons