Hydraulic Upender and Tilter manufaturer

FHOPEACK is one of leading hydraulic upender manufacturer in China. The hydraulic upending machine is designed with stability for tilting products, which can dramatically enhance the working efficiency. As a main part of the upender equipment, the hydraulic upender's performance is despends on the hydraulic system's designging.

What are the main parts of a hydraulic upender?

- Hydraulic system:The heart of the upender is its hydraulic system, which provides the power for smooth and precise positioning. It includes high-quality double-acting tilt cylinders that rotate the platforms, and a power unit that can also support secondary functions like shifting saddles and pallet centering.

- Inverter system:: The inverter system consists of rugged, heavy-duty welded steel platforms that rotate around heavy-duty pivot bearings. This system is responsible for the actual tilting action of the load.

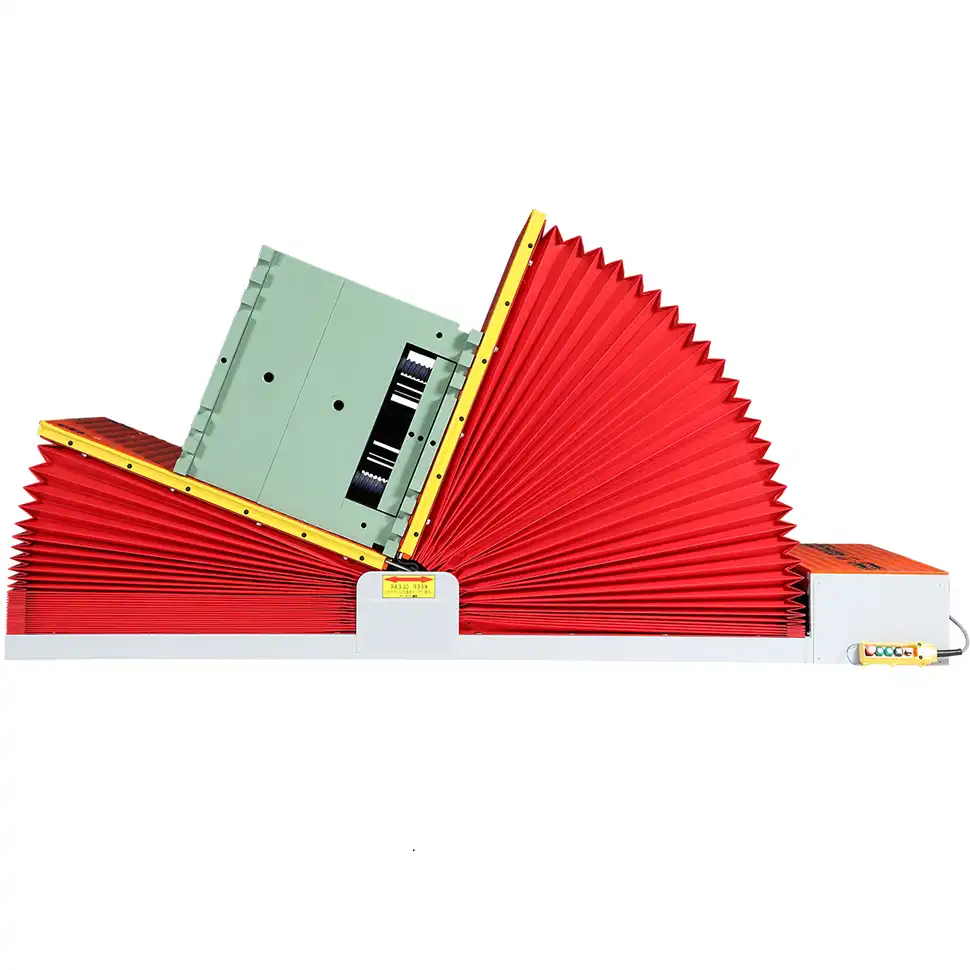

Hydraulic upender

-

Floor Base Hydraulic UpenderFloor base Hydraulic upender/Tilter is used to turn heavy objects in operation. The equipment has good stability and solid structure for handling the heavy load. The machine can be provided of easy operation and nice security for the operator.The advantage of this machine is that it has a small amount of maintenance....

-

hydraulic tilterA hydraulic tilter is a versatile machine used to tilt heavy materials like steel coils or molds with ease and precision. Its hydraulic mechanism ensures smooth operation, minimizing effort and maximizing safety. Commonly utilized in industrial settings, it improves efficiency and reduces handling risks for heavy-duty application...

-

Roll upenderA heavy-duty roll upender securely handles paper rolls, carpet rolls, and curtains. With a sturdy, durable design, it facilitates safe and efficient loading and unloading of large rolls. FHope Manufacturing provides reliable equipment for industrial material handling applications.The upender driven by hydraulic station and cylind...

-

Hydraulic coil upender for 10TThis Hydrauliccoil upender machine is a custom designed flat tilterwith a capacity of upending 40Tmold. The upend process requires raising one half of the upender 90 and then loading the tool against the raised half. Next rotates both halves simultaneously which rotates or upends the tool 90 to allow for servicing. 1.Name, mode...

-

Flipper Lift TableOur Flipper Lift Table is designed for safe and efficient flipping of molding boxes, for sand shake-off or mating response to drag. With its user-friendly design and advanced features, this equipment is capable of moving or rotating any size portion from 100 lbs to over 100 tons with just the press of a button. Our Flipper Lift T...

-

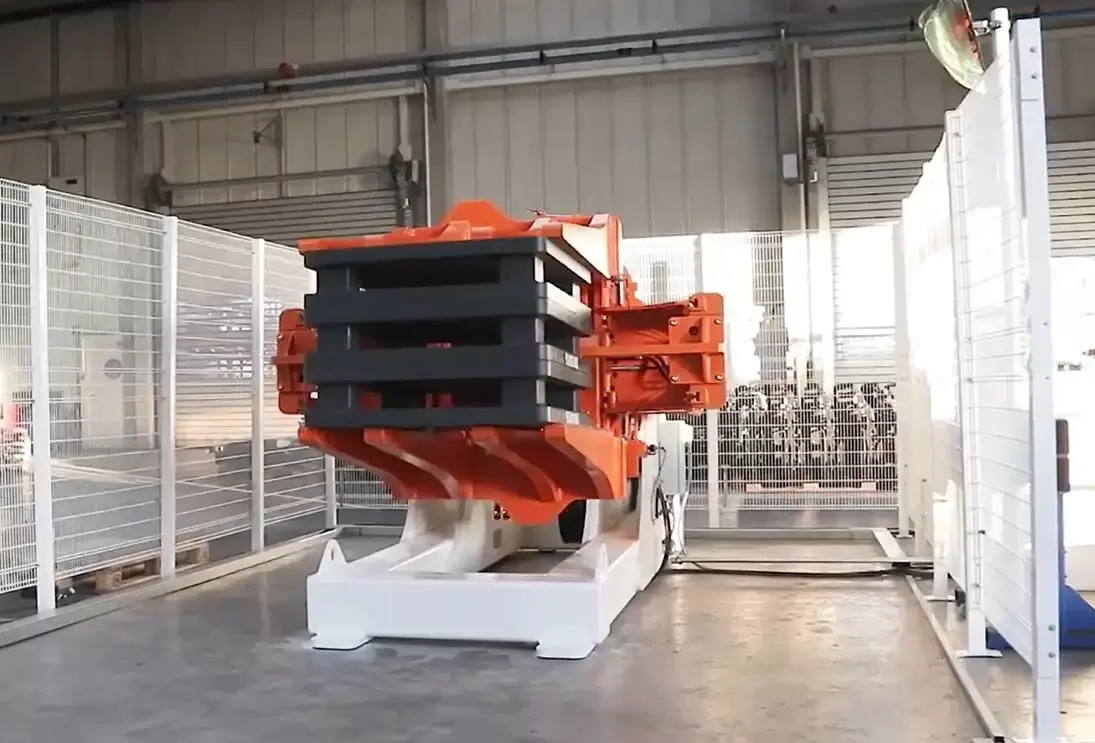

Mold flipper table | 180° Mold FlipperThe injection mold flipper table is a basic handling equipment in mold production, designed to safely and efficiently handle the turning and flipping of molds and dies with 180-degree rotation. With its advanced features and reliable performance, this equipment provides a safe and efficient solution for businesses seeking to stre...

-

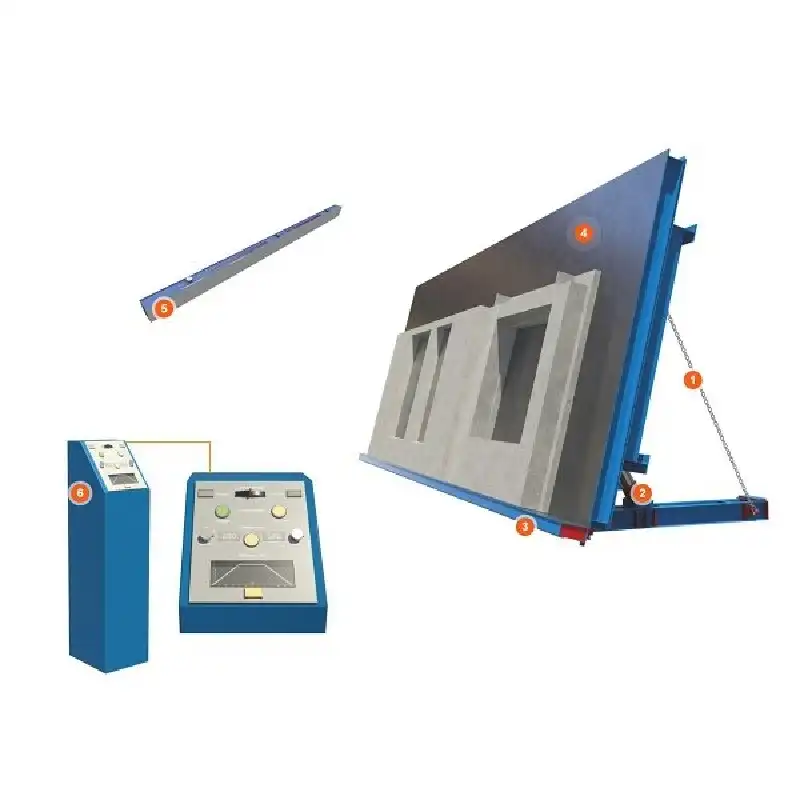

Concrete Precast Wall Tilter TableStructurally, the turntable is a steel mold, it has high strength steel for strengthening the core, the structure is stable, strong and durable. The hinged frame, which runs on the shaft via telescopic cylinders, greatly simplifies product disassembly. Rubber vibration suppressors separate the countertop from the hinged fra...

-

Paper pile turnerThe solution for Maximize your printing, publishing, or paper manufacturing operation's efficiency and productivity with a pile turner. Also called a paper pile turner, this machine flips large stacks of materials, reducing damage risk. With air blowers and vibrators, pile turners enhance quality and reduce waste. Enhance your pr...

-

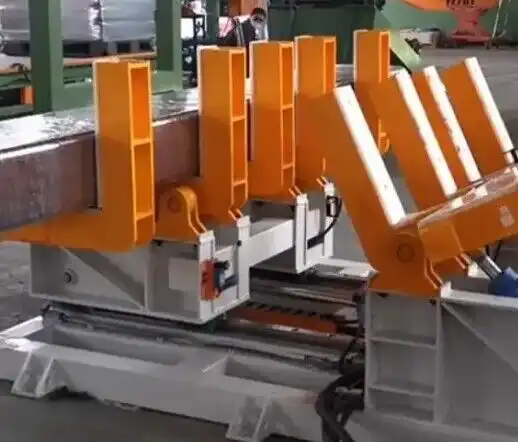

Steel Sheet Flipper and Upender machineA Heavy Capacity Hydraulic Flipper was designed and manufactured to rotate Max 12 T steel sheet from the vertical position to the horizontal / horizontal to vertical position. To assure safety, even transition and smooth operation during the tilting , the flipper features durable acting hydraulic cylinder. B asic description : Eq...

Videos

Parameters:

| Item | H02 | H05 | H10 | H20 | H40 | H50 |

|

Power Supply (V/Hz) |

AC 380/50 | |||||

|

Power (Kw) |

2.5 | 3.5 | 5.5 | 6.5 | 8.5 | 10 |

|

Max. Loading (T) |

2 | 5 | 10 | 20 | 40 | 50 |

|

Working Table (mm) |

Per Load size | |||||

|

Speed (sec) |

15-30 | 20-35 | 20-35 | 30-60 | 40-60 | 50-90 |

|

Machine Weight (T) |

1.8 | 2.2 | 2.8 | 3.0 | 3.3 | 3.6 |

|

Machine size (mm) |

Per Load shape & size | |||||

| Warrantee | 2 years | |||||

| Driving | Hydraulic | |||||

Note: The Max.Loading and working table size can be designed per different load and specification.

How to choose the proper hydraulic upender?

-

Consider load capacity: Ensure the upender can handle your heaviest loads.

- Assess load dimensions: Choose an upender that can accommodate your largest items.

-

Evaluate additional features Look for options like conveyor decks or travel capabilities if needed.

- Think about automation: If your process requires it, select a model that can be integrated into automated systems.

Why choose FHOPE for hydraulic upenders?

-

Quality construction: FHOPE likely uses high-grade materials and robust design principles.

- Customization options: 200+ sets offer tailored solutions to meet specific industry needs.

-

Safety features: FHOPE probably incorporates essential safety measures like pressure relief valves and maintenance lockout pins.

- Tested performance: Each upender is likely thoroughly 24 hour non stop tested before delivery.

ADVANTAGE:

- Safety: Hydraulic systems provide controlled and stable movement that ensures safety during the heavty load tilting process.

-

Efficiency: Hydraulic upenders offer precise control over the movement and speed of tilting, which enhances operational efficiency.

- Versatility: Engineered with user safety in mind both eletrical and mechanical, reducing the risk of workplace accidents.Used in industries like metalworking, automotive, aerospace, and manufacturing for tasks such as die handling, coil positioning, and more.

-

Longevity: Hydraulics system well-known for long operational life and minimal maintenance needs.

APPLICATIONS:

-

STEEL SHEET LOADING AND PALLET CHANGING: used to rotate steel coils and large sheets, which need to be moved from different positions

- DIE &MOULD MAINTAINMENT AND REPAIR: provides a safe and efficient way to rotate heavy dies and molds during manufacturing or maintenance.

-

PAPER ROLL HANDLING AND UPENDING: helps in the maintenance and cleaning of large printing presses by providing easier access to all sides of the equipment.

- AUTOMAOTIVE AND AEROSPACE INDUSTRY: positioning large and heavy components, such as engines, during assembly or maintenance.

-

WAREHOUSING AND LOGISTIC LOADING AND UNLOADING: facilitates the loading and unloading processes, especially for items that require orientation changes.

Frequently Asked Questions

We've compiled key FAQs about hydraulic upender projects for your convenience. If you don't find your question, call us at +8613951501635 or email [email protected].

> What is the hydraulic upender?

A hydraulic upender is a heavy-duty industrial machine designed to rotate or flip large, heavy objects—often in the manufacturing or logistics sectors. The upender's main function is to safely reposition items, such as coils, molds, pallets, or bulky components, making it easier to move, inspect, or process them. By using hydraulic power, this device offers a stable, controlled rotation that significantly reduces labor requirements and ensures safety in handling large, unwieldy items.

The upender’s structure and components are designed with durability and efficiency in mind, enabling it to handle heavy loads with minimal manual intervention.

Core Structure of the Hydraulic Upender

The hydraulic upender typically consists of a robust, stable frame, which is the machine’s main structural component. This frame is designed to handle substantial weight and includes various mounting points to anchor the machine securely to the ground, ensuring stability even when rotating heavy loads. Within the frame, the hydraulic mechanism and platform are housed, both of which play a critical role in the machine's operation.

-

Base Frame: The base frame is typically made of high-strength steel, providing a sturdy foundation that keeps the upender stable during operation. The frame must withstand the full weight of the load as well as the torque generated during rotation, which is especially important when handling items that may weigh several tons.

-

Rotational Platform: The platform is mounted to the frame and serves as the surface on which items are placed. It is generally designed to rotate at least 90 degrees, although some models may offer a 180-degree rotation for specific applications. The platform is also customizable, with designs that accommodate various product shapes and sizes.

-

Hydraulic Cylinders: These cylinders are the heart of the upender’s lifting and rotating mechanism. Powered by hydraulic fluid, these cylinders generate the force needed to lift and turn the platform. As the hydraulic pressure increases, the cylinders extend and move the platform in a controlled manner, providing a smooth and safe rotation for the objects.

-

Control Panel: Most hydraulic upenders come equipped with a control panel, allowing operators to adjust settings such as speed, rotation angle, and pressure levels. Modern control panels often have digital interfaces that enable precise adjustments and sometimes even incorporate automation features for repetitive tasks.

-

Safety Features: To ensure safe operation, hydraulic upenders are equipped with various safety mechanisms, such as emergency stop buttons, safety guards, and pressure relief valves. These components are essential in preventing accidental operation or overload, protecting both the machine and the operator.

Components and Their Functions

Each component of the hydraulic upender has a specific role in ensuring the machine’s efficiency and safety:

-

Hydraulic Power Unit (HPU): The HPU supplies the hydraulic pressure necessary to operate the cylinders. It typically includes a motor, pump, reservoir, and other components needed to generate and maintain hydraulic pressure.

-

Hydraulic Fluid Reservoir: This tank holds the hydraulic fluid used by the machine. The fluid is pressurized and circulated through the hydraulic system to move the cylinders and, consequently, the platform.

-

Pressure Relief Valves: These valves are critical for safety, releasing hydraulic fluid when pressure reaches a set limit to avoid overloading the system. This protects the machine from damage and prevents accidents during operation.

-

Rotary Bearings: Located between the frame and platform, rotary bearings enable smooth rotation. They support the platform’s weight and help distribute the load evenly, reducing friction and wear over time.

-

Locking Mechanisms: Hydraulic upenders often feature locking mechanisms that hold the platform in position when the rotation is complete. This is essential for stability, especially when the upender is being used in environments with heavy foot traffic or high levels of vibration.

Conclusion

In essence, the hydraulic upender is a crucial tool in industries where safe and efficient handling of heavy items is necessary. With a design that integrates a robust frame, rotational platform, powerful hydraulic cylinders, and a variety of safety components, it enables operators to flip heavy loads effortlessly. This machine helps improve operational efficiency, reduce manual labor, and enhance safety in handling large objects.

> Hydraulic upenders VS mechanical Upender

Hydraulic Upender vs. Mechanical Upender Comparison Table

| Feature | Hydraulic Upender | Mechanical Upender |

|---|---|---|

| Lifting Mechanism | Powered by hydraulic cylinders and fluid pressure | Uses gears, pulleys, and levers for lifting and flipping |

| Load Capacity | High capacity, suitable for very heavy loads | Moderate capacity, best for lighter or consistent loads |

| Speed Control | Adjustable speed with precise, gradual movement | Fixed or limited speed control, suitable for quick, consistent flips |

| Precision | Excellent for delicate or heavy items due to controlled movements | Less precise, with slightly more abrupt starts and stops |

| Maintenance | Higher maintenance due to hydraulic components | Lower maintenance, fewer components to maintain |

| Durability | Durable but requires regular maintenance for hydraulic components | Durable with fewer maintenance requirements |

| Safety Features | Enhanced safety with pressure relief valves, emergency stops, and smooth operation | Basic safety features like emergency stops, but less control over movement |

| Initial Cost | Higher initial investment due to complex hydraulic systems | Lower cost, simpler design |

| Best Applications | Ideal for heavy, varied loads requiring careful handling | Suitable for lighter, consistent loads where budget efficiency is key |

Summary: Hydraulic upenders provide higher load capacity, adjustable speed, and precision, making them ideal for heavy-duty tasks. Mechanical upenders, while simpler and more cost-effective, work best for consistent, lighter loads with minimal maintenance needs.

> How fast can a hydraulic upender rotate a load?

The rotation speed of a hydraulic upender depends on several factors, including the model, load weight, hydraulic power, and specific application settings. Generally, hydraulic upenders rotate at speeds between 30 seconds to 2 minutes for a full 90-degree or 180-degree flip.

Here's a breakdown of what influences rotation speed:

-

Load Weight and Size: Heavier loads generally require slower rotation speeds to ensure stability and safety, as the upender needs more hydraulic force to control the load smoothly.

-

Hydraulic System Power: Higher-powered hydraulic systems can achieve faster rotations, though this is often moderated by design to avoid compromising load safety.

-

Rotation Angle: For applications only requiring partial rotation (e.g., 45 degrees), speeds may be quicker than for a full 180-degree flip.

-

Customization and Controls: Some upenders offer adjustable rotation speed settings, allowing operators to slow down or speed up depending on the load and specific operational needs.

In industrial applications, a controlled speed is typically preferred over high-speed rotation, as it ensures both load stability and operator safety, especially for delicate or heavy materials.

> How much does hydraulic upenders cost?

The cost of hydraulic upenders can vary widely based on factors like capacity, size, customization, and features. Here’s a general price range:

-

Small-Capacity Hydraulic Upenders (1-5 tons): Typically range from $5,000 to $10,000. These are suitable for lighter loads and are often used in smaller manufacturing setups or workshops.

-

Mid-Range Capacity (5-20 tons): The cost usually falls between $10,000 and $25,000. These upenders can handle moderate loads and are commonly used in manufacturing and assembly lines.

-

High-Capacity Hydraulic Upenders (20-50 tons or more): Generally priced from $25,000 to $75,000 or higher. They’re ideal for industries dealing with heavy materials like steel coils or large molds.

-

Customized and Heavy-Duty Models (above 50 tons): Can exceed $100,000, especially when advanced automation or safety features are included. These are typically custom-built to handle unique requirements in industries like automotive, aerospace, or large-scale manufacturing.

Additionally, installation, shipping, and maintenance costs may add to the overall expense. Prices can also fluctuate depending on the brand, regional suppliers, and current market demand.

> How much maintenance do hydraulic upenders require?

Hydraulic upenders require moderate maintenance to ensure optimal performance, safety, and longevity. Here’s a breakdown of the typical maintenance needed:

1. Daily or Pre-Shift Checks

- Visual Inspection: Inspect for any visible signs of wear, leaks, or damage on hydraulic hoses, fittings, and other exposed components.

- Fluid Levels: Check hydraulic fluid levels and top off if necessary. Low fluid can reduce operational efficiency and cause damage.

- Control Functionality: Test control systems and safety mechanisms to confirm smooth, responsive operation and emergency stop function.

2. Weekly Maintenance

- Lubrication: Lubricate moving parts, especially those under heavy load or experiencing frequent movement, such as bearings and rotating joints.

- Hydraulic Fluid Inspection: Inspect the hydraulic fluid for contamination or discoloration, which may indicate a need for replacement.

- Check Fastenings: Tighten bolts, screws, and fasteners as needed, especially on critical load-bearing components.

3. Monthly Maintenance

- Hydraulic System Check: Examine the hydraulic pump, cylinders, and hoses more thoroughly for leaks or wear, as minor issues may not be apparent during daily checks.

- Alignment and Calibration: Check that the upender’s alignment and rotation angles remain calibrated. Minor adjustments may be needed to maintain accuracy.

- Filter Inspection: Inspect the hydraulic filters and replace them if they show signs of clogging. Clogged filters reduce fluid quality and system performance.

4. Quarterly Maintenance

- Hydraulic Fluid Replacement: Depending on usage, replace the hydraulic fluid every three to six months to prevent contamination and ensure smooth operation.

- Detailed System Inspection: Inspect all components, such as cylinders, hoses, seals, and valves, for any signs of advanced wear or damage.

- Electrical System Check: Inspect wiring, connections, and control panels for any damage or corrosion that could affect functionality.

5. Annual Maintenance

- Comprehensive Overhaul: Conduct a full inspection and servicing of the hydraulic system, electrical components, safety features, and structural integrity.

- Professional Calibration: Have the upender calibrated by a professional technician if needed, especially for systems integrated into automated production lines.

- Replace Worn Parts: Proactively replace any worn parts identified during the inspection, even if they are still functional, to prevent future breakdowns.

Additional Maintenance Considerations

- Usage-Based Adjustments: High-frequency usage or heavy-duty applications may require more frequent checks, especially for hydraulic fluids, seals, and hoses.

- Environmental Factors: Dusty or dirty environments may necessitate more frequent filter changes and cleaning to maintain optimal performance.

Regular maintenance of hydraulic upenders is crucial to avoid downtime and costly repairs, with daily checks and monthly inspections providing a solid preventive routine. With proper maintenance, hydraulic upenders can perform reliably for many years, supporting safe and efficient operations.

> Why purchase a hydraulic upender from China?

In recent years, China has emerged as a leading supplier of industrial equipment, particularly in hydraulic machinery like upenders. A hydraulic upender is a powerful machine used to flip or rotate heavy loads, essential in manufacturing, metallurgy, and various other sectors. For companies globally, buying a hydraulic upender from China offers distinct advantages, including cost-effectiveness, product variety, quality standards, and customized service. This article examines the reasons why companies should consider sourcing their hydraulic upenders from China.

1. Cost-Effectiveness and Competitive Pricing

One of the primary reasons companies look to China for industrial machinery is the competitive pricing. Chinese manufacturers benefit from economies of scale and lower labor costs, enabling them to offer high-quality hydraulic upenders at a fraction of the price compared to Western suppliers. Here’s how this translates to cost savings:

- Reduced Manufacturing Costs: China has developed extensive supply chains, giving manufacturers easier access to raw materials and components at lower costs.

- Competitive Labor Rates: Due to lower labor expenses, Chinese manufacturers can offer high-quality products without inflating prices.

- Volume Production: Many Chinese manufacturers produce hydraulic upenders in high volumes, allowing them to further lower the per-unit cost.

The result is that companies can purchase reliable, well-built upenders at a lower investment, enabling them to allocate resources to other areas or increase operational efficiency with less upfront cost.

2. High Quality and Compliance with International Standards

In the past, buyers were cautious about quality when purchasing from China, but significant improvements over the years have reshaped the country’s manufacturing reputation. Chinese manufacturers now regularly adhere to international quality standards like ISO 9001, CE, and UL, and many are equipped to meet stringent requirements for durability, safety, and efficiency. Benefits of Chinese quality standards include:

- Advanced Manufacturing Processes: Many Chinese manufacturers utilize the latest technologies in hydraulics and electronics, allowing them to produce upenders that are not only robust but also energy-efficient.

- Stringent Quality Control: Reputable manufacturers have rigorous quality control measures, ensuring that each unit meets strict safety and performance standards.

- Global Compliance: Compliance with international standards makes Chinese hydraulic upenders suitable for export to North America, Europe, and other regulated markets.

For companies prioritizing reliability and safety, the high quality of Chinese upenders offers a cost-effective alternative to traditional Western suppliers without compromising performance.

3. Extensive Product Variety and Customization Options

Chinese suppliers provide a wide range of hydraulic upenders, catering to diverse industries and needs. Whether it’s a light-duty upender for small manufacturing applications or a heavy-duty machine for large steel coils, Chinese manufacturers offer extensive product lines, and most suppliers are open to customization requests. This range and flexibility provide buyers with specific solutions tailored to their unique applications.

- Customizable Capacity and Dimensions: Chinese manufacturers can adjust upender specifications, such as lifting capacity, rotation angle, and size, to meet specific operational requirements.

- Choice of Additional Features: Buyers can select from a variety of optional features, such as automated control systems, advanced safety mechanisms, and remote operation capabilities.

- Versatility Across Industries: Hydraulic upenders from China are designed to accommodate a wide array of industrial applications, including automotive, aerospace, logistics, and heavy manufacturing.

The ability to customize hydraulic upenders ensures that companies get the exact product they need for their production lines, without incurring the additional costs often associated with custom orders in Western markets.

4. Rapid Production and Delivery Times

China’s manufacturing infrastructure enables rapid production times, ensuring faster turnaround from order to delivery. Manufacturers operate within well-established industrial networks, allowing them to source materials quickly and streamline the production process. This responsiveness is ideal for companies that need new equipment urgently or require replacements for existing machinery.

- Efficient Supply Chains: Chinese manufacturers benefit from close proximity to suppliers of raw materials, components, and electronics, reducing delays in the production process.

- Bulk Production Capability: High-volume production allows for quicker lead times, especially for standard models that are continuously manufactured and ready for shipping.

- Logistics and Shipping Options: With access to major ports and established logistics networks, Chinese manufacturers can offer various shipping methods, ensuring timely delivery at competitive rates.

This rapid production capability is particularly advantageous in industries with tight project timelines or high-demand environments where downtime is costly.

5. Strong After-Sales Support and Global Presence

Chinese manufacturers have increasingly emphasized after-sales service and customer support, which has led to higher customer satisfaction and trust. Many companies provide comprehensive after-sales services, including installation guidance, technical support, maintenance training, and spare parts supply, ensuring smooth operation post-purchase. Key aspects include:

- Technical Support and Training: Many manufacturers offer virtual or on-site training, which helps buyers optimize the use of the hydraulic upender and ensure proper maintenance.

- Warranty and Replacement Parts: Reputable suppliers provide warranties and spare parts, allowing customers to address any equipment issues promptly.

- 24/7 Customer Service: Given the time zone differences, Chinese manufacturers often offer 24/7 support to assist international clients, ensuring any concerns are quickly resolved.

These after-sales services build long-term relationships with international customers, providing assurance that they can rely on their equipment and receive support if needed.

6. Innovation and Advancements in Hydraulic Technology

Chinese manufacturers are making substantial investments in research and development (R&D), resulting in frequent innovations in hydraulic technology. Many Chinese upenders now feature energy-saving designs, improved safety functions, and enhanced automation, which benefit production efficiency and reduce operating costs. Key innovations include:

- Energy Efficiency: Newer models include energy-efficient hydraulic systems that reduce power consumption, aligning with global sustainability goals.

- Safety Enhancements: Advanced safety features such as emergency stops, pressure sensors, and stability control systems improve operator safety.

- Integration with Automation Systems: Some hydraulic upenders can be integrated into fully automated production lines, allowing seamless operation with other machinery and control systems.

These technological advancements position Chinese hydraulic upenders as competitive products in the global market, especially for companies looking to modernize their manufacturing operations.

7. Established Reputation and Global Market Presence

Chinese manufacturers have a growing reputation for reliability in the global market. Many of the leading brands are well-known worldwide and have successfully exported hydraulic upenders to North America, Europe, Southeast Asia, and beyond. Companies can benefit from a supplier that has experience with global standards and understands the expectations of international customers.

- Proven Track Record: Reputable Chinese manufacturers have a portfolio of international clients, which speaks to their experience and reliability.

- Positive Customer Reviews: Many Chinese brands enjoy positive feedback from users worldwide, affirming the durability and performance of their hydraulic upenders.

Conclusion

Purchasing a hydraulic upender from China offers a range of benefits for companies worldwide. The combination of competitive pricing, high-quality standards, extensive customization options, fast production times, and strong after-sales support makes Chinese hydraulic upenders an attractive option. Additionally, with innovations in hydraulic technology and a well-established reputation in the international market, Chinese suppliers provide reliable and efficient solutions for diverse industrial applications.

> Are there any safety certifications I should look for when purchasing a hydraulic upender?

>What support does FHOPE offer for hydraulic upender installation and maintenance?

FHOPE, a leading Chinese supplier of hydraulic upenders, offers a robust support system for installation, maintenance, and ongoing technical assistance to ensure smooth operation and customer satisfaction. Here’s an overview of the support FHOPE provides:

1. Installation Assistance

- On-Site Installation: For large-scale or custom upenders, FHOPE offers on-site installation services where their engineers assist in setting up the equipment, ensuring it’s correctly configured and calibrated for the specific operational environment.

- Remote Installation Guidance: For customers who do not require on-site support, FHOPE provides detailed guidance via remote video support, instructional materials, and step-by-step manuals to aid the installation process.

- Training for Operators: FHOPE offers training sessions, either on-site or virtual, for operators and maintenance teams to familiarize them with the equipment, focusing on safety, operational controls, and daily maintenance tasks.

2. Technical Support and Troubleshooting

- 24/7 Customer Service: FHOPE’s technical support team is available around the clock to assist international clients, addressing issues or questions in real time, which is particularly valuable given the time zone differences.

- Troubleshooting Assistance: They provide remote troubleshooting support, guiding clients through common issues and repairs. This can include step-by-step instructions and video guides for more complex repairs or operational troubleshooting.

- Dedicated Account Managers: Each client is often assigned an account manager who can coordinate quick responses to technical inquiries, maintenance requests, or spare part orders.

3. Preventative Maintenance Support

- Scheduled Maintenance Plans: FHOPE offers custom maintenance schedules that help clients keep up with routine check-ups and servicing. This can include detailed maintenance checklists and timelines to extend the lifespan of the upender.

- Regular Inspection Services: For clients who opt for extended service packages, FHOPE can arrange periodic on-site inspections, where a technician assesses equipment wear, performs necessary adjustments, and recommends any parts replacements to prevent future issues.

4. Spare Parts and Replacement Services

- Quick-Ship Spare Parts: FHOPE maintains an inventory of critical spare parts for their hydraulic upenders, allowing clients to quickly order and receive parts in the event of a malfunction.

- Warranty and Replacement Coverage: Many of their upenders come with a warranty covering parts replacement and service, offering peace of mind for initial repairs and adjustments.

- Parts Manuals: Each hydraulic upender comes with a parts catalog and manual, allowing maintenance teams to identify and order parts easily.

5. Upgrades and Retrofitting

- System Upgrades: FHOPE provides options for software and hardware upgrades to improve the functionality or capacity of existing upenders. This could include automation features, new control systems, or safety enhancements.

- Retrofitting Services: For clients with older models, FHOPE offers retrofitting to bring equipment up to current standards, including enhancements in energy efficiency, safety, and operational ease.

6. Customized Training and Support Materials

- Customized Manuals: They provide manuals tailored to specific model configurations, covering installation, operation, and maintenance.

- Video Tutorials and Training Modules: FHOPE’s training materials include video tutorials and digital training modules that operators and technicians can reference as needed, making it easier to perform routine maintenance and troubleshoot issues.

FHOPE’s support infrastructure is designed to help clients maximize the performance and longevity of their hydraulic upenders, reduce downtime, and maintain a high level of operational safety and efficiency. This comprehensive approach to installation, maintenance, and support reflects their commitment to customer satisfaction and long-term equipment reliability.

Download

|

|

|

|

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635