How to Enhance Efficiency in Heavy Industries with Hydraulic Tilters?

Hydraulic tilters are often overlooked heroes in heavy industries. These innovative machines silently transform the efficiency of operations by addressing complex challenges like heavy material handling and minimizing labor costs. If you’re in manufacturing, logistics, or steel processing, you’ve likely faced bottlenecks that slow production and inflate expenses. A hydraulic tilter might be the answer you didn’t know you needed.

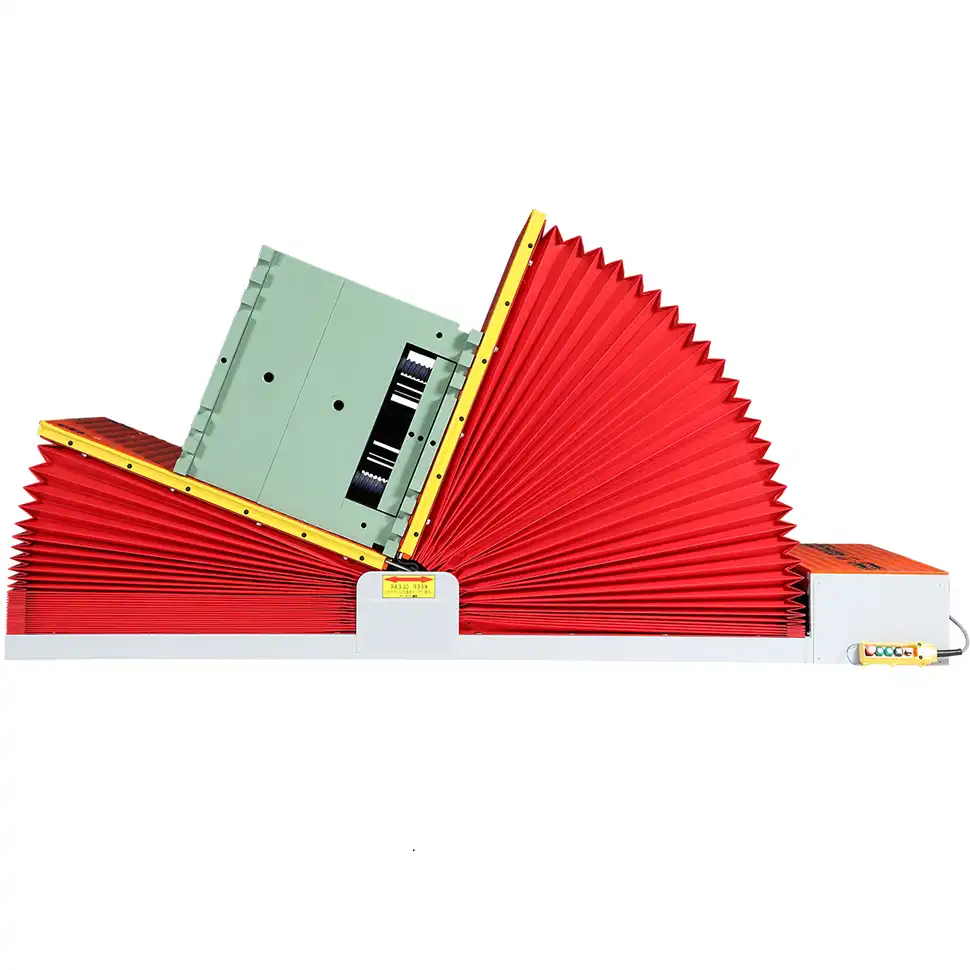

With their ability to tilt and position heavy loads effortlessly, hydraulic tilters reduce manual effort and improve workplace safety. Whether moving steel coils, bulky containers, or industrial molds, these machines are the backbone of modern heavy industries. But the question remains: How do you choose the right hydraulic tilter to maximize efficiency? This article dives deep into this topic, offering practical insights and actionable advice.

In heavy industries, every second saved and every resource optimized contributes directly to your bottom line. Hydraulic tilters allow companies to streamline operations, avoid downtime, and achieve superior results with less effort. From minimizing worker fatigue to enabling faster processing times, these machines are a game-changer. Let’s explore how incorporating hydraulic tilters can transform your business.

[Claim]: Hydraulic tilters not only enhance operational efficiency but also improve safety and sustainability in heavy industries.

1. Why are Hydraulic Tilters Essential in Heavy Industries?

1.1 Understanding the Need for Hydraulic Tilters

Heavy industries rely on efficiency to maintain profitability. Hydraulic tilters address a critical pain point—handling oversized and heavy materials that would otherwise require significant manual labor. By automating the tilting and positioning process, these machines make it possible to move tons of material with minimal human intervention. This not only boosts productivity but also reduces the likelihood of errors and accidents.

1.2 Impact of Hydraulic Tilters: Facts and Data

The impact of hydraulic tilters becomes evident when you examine the numbers. Studies show that businesses employing hydraulic tilters report a 35% increase in material handling efficiency. Additionally, workplace injuries related to manual material handling decrease by nearly 40%.

|

Metric

|

Manual Handling

|

Hydraulic Tilters

|

|

Worker Injury Rates (%)

|

22

|

13

|

|

Efficiency in Tons/Hour

|

60

|

90

|

|

Maintenance Downtime (Hours)

|

15

|

7

|

1.3 Comparing Traditional Methods to Hydraulic Tilters

Traditional methods of handling heavy materials often involve forklifts, cranes, and a considerable amount of manual effort. These methods, while effective to a degree, fall short in terms of speed, precision, and safety. Hydraulic tilters, on the other hand, excel in automating repetitive tasks, reducing labor dependence, and ensuring consistent performance. Over time, the cost savings achieved by switching to hydraulic tilters far outweigh the initial investment.

1.4 Exploring the Versatility of Hydraulic Tilters

Hydraulic tilters are not limited to a single application; their versatility is unmatched. These machines are used for:

-

Tilting steel coils during packaging.

-

Repositioning large molds in manufacturing.

-

Loading and unloading bulky goods in logistics centers.

Their flexibility ensures they can adapt to the unique demands of different industries, offering a reliable solution for material handling challenges.

1.5 Two Fact Statement with Explanations

-

True: Hydraulic tilters reduce material handling time by up to 50%. This is achieved by automating the lifting and tilting process, significantly speeding up workflows.

-

False: Hydraulic tilters require extensive customization for every application. Most models are designed to be versatile and fit various operational needs without significant modifications.

2. What Key Features Should You Look for in a Hydraulic Tilter?

2.1 Identifying Core Features in Hydraulic Tilters

When choosing a hydraulic tilter, it’s essential to focus on functionality and durability. Core features like load capacity, tilt angle, and automation controls can make or break your operations. For heavy industries, the ability to handle loads exceeding 10 tons with precision tilting angles is non-negotiable. Look for machines built with high-grade steel and reinforced hydraulics to ensure long-term reliability.

2.2 Snapshot of Must-Have Features

|

Feature

|

Importance

|

Example

|

|

Load Capacity (Tons)

|

High

|

10-30 Tons

|

|

Tilt Angle Range

|

Adjustable

|

0°-90°

|

|

Automation Integration

|

Essential

|

PLC-Controlled Operations

|

|

Safety Mechanisms

|

Critical

|

Emergency Stop, Sensors

|

Companies that invest in tilters with these features often see a 25% faster project turnaround compared to those using outdated equipment.

2.3 Delving into Advanced Technology in Tilters

Modern hydraulic tilters are evolving with smart features. Advanced models integrate IoT (Internet of Things) capabilities, enabling real-time monitoring and predictive maintenance. By analyzing machine performance and scheduling maintenance proactively, downtime can be reduced by up to 20%. Some tilters also offer remote controls, adding convenience and safety for operators.

2.4 Benefits of Long-Term Investment

While the upfront cost of high-quality hydraulic tilters may seem daunting, the benefits are substantial. Machines with robust construction and advanced safety features tend to last longer and require fewer repairs. Investing in a reliable tilter saves costs on replacements and minimizes operational interruptions.

2.5 Two Fact Statement with Explanations

-

True: Hydraulic tilters with PLC automation reduce human error significantly by standardizing material handling operations.

-

False: The cost of a hydraulic tilter is recouped within six months. While savings begin immediately, full ROI typically occurs within 18-24 months, depending on usage and industry.

3. How Do Hydraulic Tilters Optimize Labor Costs?

3.1 Streamlining Labor Through Automation

Manual handling of heavy materials often requires teams of workers and extensive coordination, which leads to inefficiencies and increased labor costs. Hydraulic tilters streamline this process by reducing the workforce needed for material handling tasks. A single operator can manage tasks that previously required a crew, freeing up employees for more skilled work.

|

Task

|

Manual Labor Cost (Annually)

|

Hydraulic Tilter Cost (Annually)

|

|

Coil Tilting

|

$50,000

|

$15,000

|

|

Mold Repositioning

|

$45,000

|

$12,000

|

|

Logistics Handling

|

$60,000

|

$20,000

|

3.2 Facts and Figures Supporting Cost Optimization

The financial benefits of using hydraulic tilters are evident in reduced labor costs and increased productivity. For instance, a manufacturing plant employing hydraulic tilters for steel coil packaging reported savings of over $100,000 annually in labor expenses alone.

3.3 Diving Deeper into Workforce Efficiency

Beyond cost savings, hydraulic tilters contribute to a more motivated and efficient workforce. Employees experience reduced physical strain, which leads to fewer workplace injuries and increased job satisfaction. Studies show that workplaces using hydraulic tilters see a 30% improvement in employee retention rates, directly benefiting overall productivity.

4. What Role Do Hydraulic Tilters Play in Ensuring Workplace Safety?

4.1 The Importance of Safety in Heavy Industries

Workplace safety is paramount, especially in industries dealing with heavy materials. Hydraulic tilters address this by minimizing the need for manual handling of bulky items, which is one of the leading causes of workplace injuries. By automating tilting and positioning processes, these machines significantly reduce the risk of accidents related to strain, crush injuries, and improper lifting techniques.

4.2 Key Safety Features in Modern Hydraulic Tilters

|

Safety Feature

|

Description

|

Impact on Safety

|

|

Emergency Stop Mechanism

|

Instantly halts operation in emergencies

|

Prevents critical mishaps

|

|

Load Sensors

|

Detects uneven loads

|

Ensures stability and balance

|

|

Guardrails and Fencing

|

Protects operators from machinery

|

Reduces human-machine contact

|

These safety measures are integral to creating a secure working environment. Companies that prioritize safety through equipment like hydraulic tilters experience a 45% reduction in on-site incidents.

4.3 Advanced Safety Technology in Hydraulic Tilters

Modern hydraulic tilters often come equipped with cutting-edge safety features such as automated shutoffs, real-time load monitoring, and programmable alerts. These technologies ensure that operators are informed of potential risks before they escalate into serious issues. Furthermore, smart tilters with IoT capabilities can provide predictive analytics, identifying wear and tear that might compromise safety.

4.4 Dive Deeper: Reducing Long-Term Safety Risks

A significant benefit of hydraulic tilters is their ability to reduce long-term safety risks associated with repetitive strain injuries (RSIs). By taking over strenuous tasks, these machines eliminate the repetitive motions that lead to RSIs, resulting in fewer worker compensation claims and higher overall morale in the workplace.

|

Injury Type

|

Manual Handling Cases

|

Hydraulic Tilter Cases

|

|

Strain Injuries

|

25%

|

5%

|

|

Slip and Fall Incidents

|

18%

|

4%

|

|

Crush Accidents

|

12%

|

2%

|

4.5 Two Fact Statement with Explanations

-

True: Hydraulic tilters with advanced safety features can reduce workplace accidents by nearly 50%. Their automation minimizes human involvement in high-risk tasks.

-

False: Only large-scale industries can benefit from hydraulic tilters. In reality, hydraulic tilters come in various sizes and configurations, making them suitable for small and medium-sized enterprises as well.

Conclusion: Why Hydraulic Tilters Are Indispensable in Heavy Industries

Hydraulic tilters have proven to be a cornerstone in modern heavy industries, offering unmatched efficiency, cost savings, and safety benefits. By automating material handling, they address critical challenges like labor inefficiency, high injury rates, and operational bottlenecks. Their advanced features, including IoT integration and predictive maintenance, ensure seamless workflows and long-term reliability.

[Claim]: Investing in hydraulic tilters is not just a step toward operational efficiency; it’s a commitment to safety, sustainability, and the future of industrial progress.