COIL TURNER | COIL TURNING MACHINE

A coil turner, or coil turning machine, is a vital tool for industries handling heavy steel or metal coils, designed to ensure safe and efficient rotation and positioning of coils while eliminating the risks associated with manual handling. This equipment enhances workplace safety, boosts productivity, and reduces labor costs by streamlining the coil handling process. Engineered to accommodate various coil sizes and weights, it provides smooth and precise turning for applications in steel manufacturing, automotive production, and logistics. Its durable construction minimizes downtime and maintenance costs, making it a reliable solution for improving operational efficiency. Whether used for storage, transportation, or further processing, a coil turner is an indispensable asset for optimizing safety and productivity in demanding industrial environments.

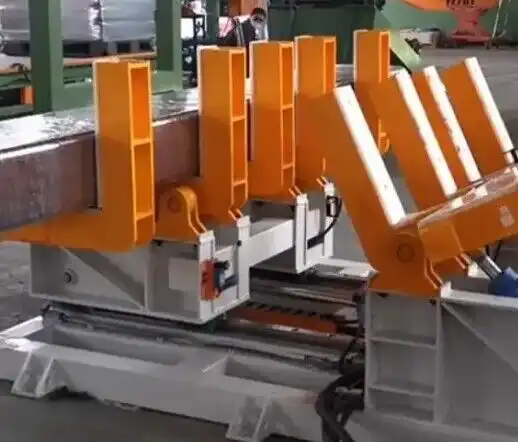

1. Mechanical Coil Turner

The mechanical coil turner provides a simple and reliable solution for rotating heavy coils with precision and ease. Designed for durability and straightforward operation, this machine enables safe and efficient turning of coils without relying on hydraulic systems or complex mechanisms. Its robust construction ensures consistent performance, making it a cost-effective choice for industries handling medium to heavy loads. With minimal maintenance requirements and user-friendly controls, the mechanical coil turner is perfect for applications where simplicity and reliability are paramount.

Key Features: Robust Construction, Manual Operation, Cost-Effective, Low Maintenance, Reliable Performance

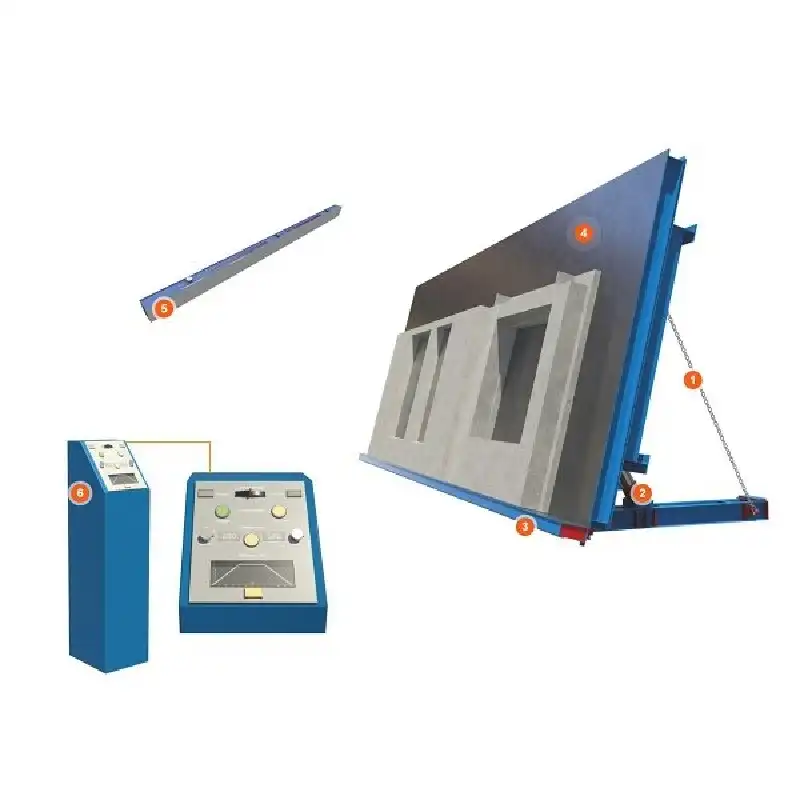

2. Hydraulic Coil Turner

The hydraulic coil turner delivers a powerful and efficient solution for rotating heavy-duty coils with precision and control. Engineered for industrial environments, this machine utilizes a robust hydraulic system to safely handle and turn coils of various sizes and weights. Its advanced controls and smooth operation ensure maximum safety and efficiency during handling. Built to withstand demanding applications, the hydraulic coil turner is ideal for businesses requiring a high-capacity solution with reliable performance.

Key Features: High Load Capacity, Smooth Hydraulic Operation, Durable Design, Safety-Focused Controls, Efficient and Reliable

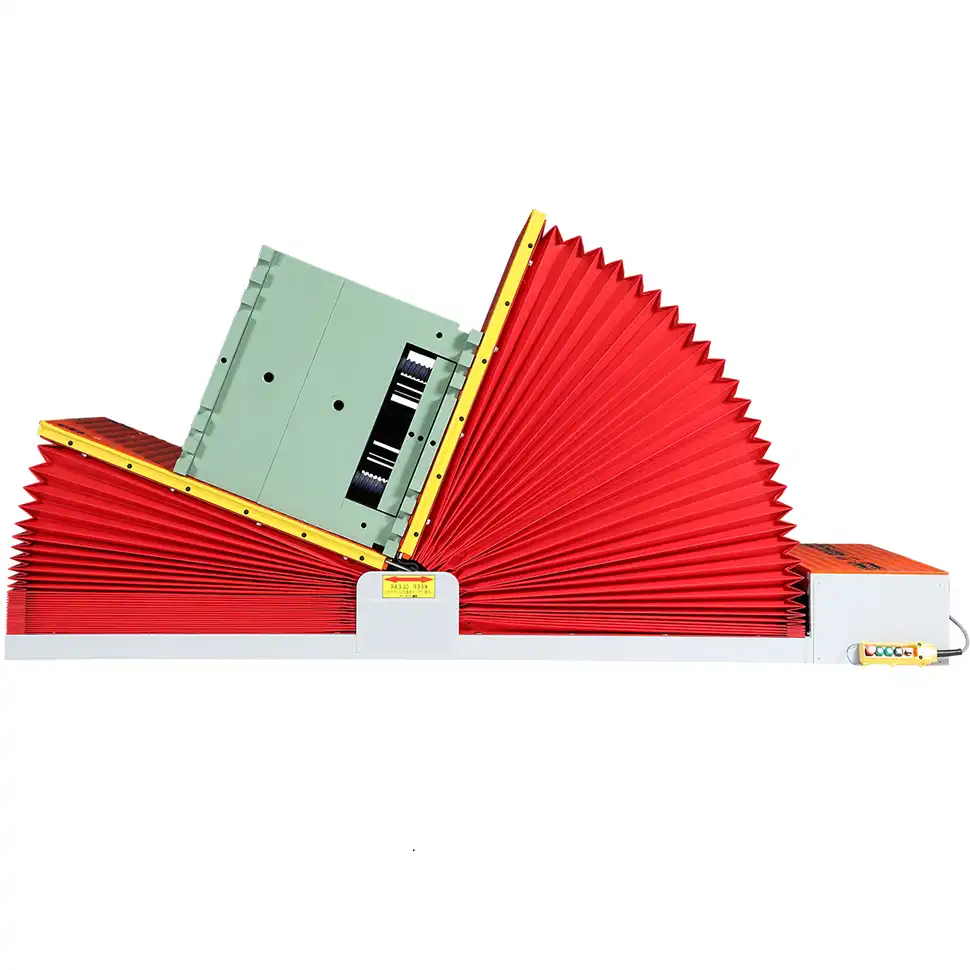

3. Customized Coil Turner

The customized coil turner is designed to meet the specific requirements of your material handling operations. Whether you need to handle unique coil dimensions, extra-heavy loads, or specialized turning angles, this machine offers a tailored solution for your business. Its flexible design and advanced engineering ensure optimal performance, safety, and seamless integration into your workflow. Perfect for handling challenging or irregularly shaped coils, the customized coil turner delivers exceptional adaptability and reliability for specialized applications.

Key Features: Customizable Design, Precision Engineering, High Load Adaptability, Seamless Integration, Enhanced Safety Features

Coil Turner

-

Coil Turner For SaleStreamline your coil handling process with our advanced coil turner. Built for durability and precision, it allows for safe and efficient rotation of heavy coils. Perfect for industrial environments, it reduces labor strain, enhances safety, and boosts productivity. A reliable, cost-effective solution for your material handling n...

-

Coil Turner ManufacturerA coil turner manufacturer provides innovative machinery designed to rotate and position heavy coils with precision. Their products improve operational efficiency, minimize workplace injuries, and support diverse industries such as steel manufacturing, wire production, and metal processing. Offering durable, customizable solution...

-

Coil Turner PriceA coil turner provides a cost-effective way to handle heavy coils, offering competitive pricing without compromising safety or efficiency. It minimizes manual labor, improves operational workflow, and ensures durability, making it a smart investment for industries dealing with steel, aluminum, or wire coils....

-

Steel Coil TurnerThe Steel-Coil-Turner is a robust and efficient machine designed to handle and rotate steel coils safely. Ideal for industrial settings, it enhances operational efficiency, reduces manual labor, and minimizes workplace risks. With durable construction and customizable features, it ensures precise coil handling, making it a reliab...

-

Aluminum Coil TurnerThe Aluminum-Coil-Turner is a reliable solution for handling and rotating aluminum coils with precision and safety. Designed for industrial applications, it enhances productivity, minimizes manual effort, and ensures secure operations. Its robust construction and customizable options make it ideal for improving workflow efficienc...