What to Consider Before Buying a Box Wrapper: A Comprehensive Buying Guide

Choosing the right box wrapping machine can drastically affect your packaging efficiency, safety, and overall production costs. However, the decision-making process is far from straightforward. With so many options available in the market, it’s easy to feel overwhelmed. Whether you need a machine to streamline operations or meet specific compliance standards, this guide will help you navigate the complexities and make an informed decision.

Box wrapping machines are not just about functionality; they’re about creating value for your operations. The right equipment can optimize labor costs, reduce material waste, and boost production efficiency, but only if chosen carefully. Let’s explore the key factors you should consider before purchasing a box wrapper.

Investing in the wrong machine can lead to inefficiencies, higher maintenance costs, and potential safety hazards. On the other hand, selecting the ideal box wrapper can ensure long-term performance, compliance with safety standards, and a significant return on investment. Here's everything you need to know to make a confident choice.

The right box wrapper isn’t just a machine; it’s a strategic tool that enhances productivity, ensures safety, and supports long-term growth.

1. How Can You Enhance Safety in Box Packaging with the Right Equipment?

1.1 Safety Features That Matter Most

When it comes to box wrapping, safety is paramount. The right equipment can help prevent workplace accidents, minimize downtime, and ensure compliance with occupational safety standards. Key safety features to look for include:

- Emergency Stop Mechanisms: These allow operators to halt operations instantly in case of a malfunction.

- Automatic Load Detection: Prevents overloading, which could lead to machine failure or safety hazards.

- Guarding Systems: Protective barriers around moving parts reduce the risk of accidental injury.

- User-Friendly Interfaces: Intuitive controls minimize operator errors, which are a leading cause of workplace accidents.

1.2 Key Statistics on Workplace Safety in Packaging

To emphasize the importance of safety, let’s look at some key data:

| Statistic | Value |

|---|---|

| Annual workplace injuries in packaging | 40,000+ cases (U.S.) |

| Percentage caused by equipment failures | 25% |

| Reduction in accidents with safety-certified machines | 60% |

These statistics highlight the necessity of investing in machines with robust safety features.

1.3 Common Safety Pitfalls in Box Wrapping

Even with advanced equipment, some common mistakes can compromise safety:

- Ignoring Preventive Maintenance: Regular servicing ensures that safety features remain functional.

- Improper Training: Operators must be well-trained on the specific machine to avoid misuse.

- Overlooking Ergonomics: Machines that are difficult to operate can cause fatigue and increase the likelihood of errors.

By addressing these issues, companies can create a safer working environment and maximize the benefits of their box wrapping machines.

1.4 In-Depth Look at Safety Standards and Certifications

Before purchasing a box wrapper, it’s crucial to ensure that the equipment complies with recognized safety standards. These certifications not only safeguard your workforce but also enhance your company’s reputation for responsible operations.

- ISO 13849: Ensures that safety-related parts of machinery are designed to prevent failures.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- ANSI B11: Covers safety requirements for industrial machinery in the U.S.

Incorporating these standards into your purchasing decision reduces liability and builds trust with stakeholders.

1.5 Two Fact Statements

Fact 1 (True): Machines with advanced safety features can reduce workplace accidents by up to 60%.

Fact 2 (False): Manual box wrapping is just as safe as using automated equipment, provided the staff is well-trained.

Explanation: While training is essential, manual wrapping involves more physical strain and a higher risk of repetitive stress injuries compared to automated solutions.

2. What Should You Consider When Choosing the Optimal Box Wrapper for Your Needs?

2.1 Understanding Your Operational Requirements

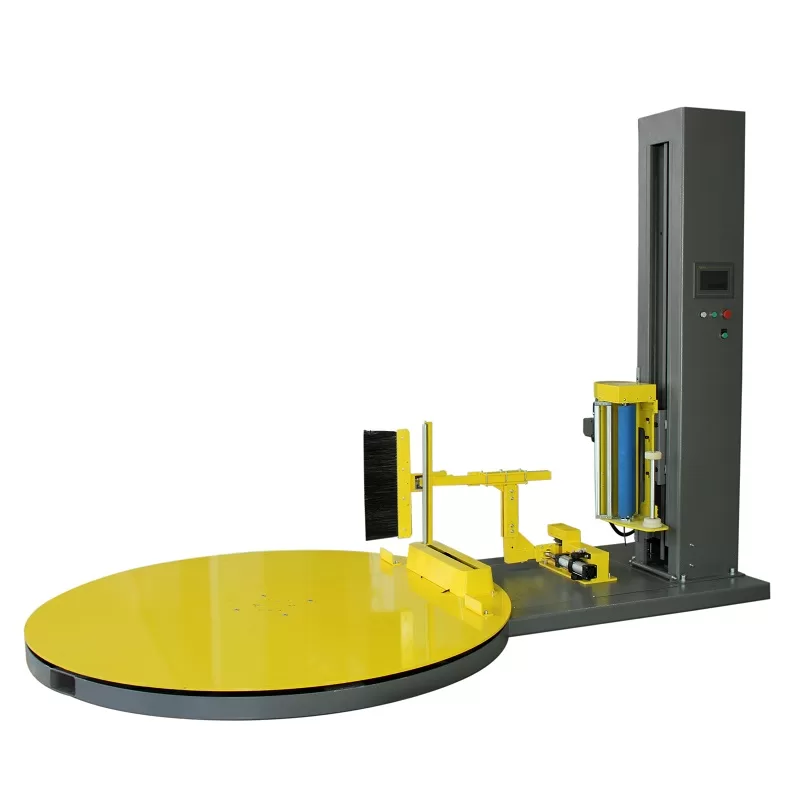

When selecting the optimal box wrapper, the first step is understanding your specific operational needs. Factors such as production volume, load sizes, and packaging materials play a crucial role in determining the right machine. For example:

- High-Volume Operations: Fully automated systems are ideal for operations handling thousands of boxes per day. These machines can streamline workflows and minimize manual intervention.

- Small to Medium Enterprises (SMEs): Semi-automated machines offer a balance between affordability and efficiency, making them a practical choice for SMEs.

- Specialized Packaging Needs: If your packaging involves irregularly shaped boxes or fragile materials, consider machines with customizable settings and advanced sensors.

Choosing a machine tailored to your needs ensures long-term efficiency and cost-effectiveness.

2.2 Key Statistics and Comparison Table

To better understand the differences between machine types, here’s a quick snapshot:

| Feature | Fully Automated Machines | Semi-Automated Machines |

|---|---|---|

| Speed | 60-80 wraps/hour | 20-30 wraps/hour |

| Operator Involvement | Minimal | Moderate |

| Initial Cost | $25,000–$60,000 | $8,000–$20,000 |

| Best For | High-volume, standardized loads | Low-to-medium volume, variable loads |

Industry Insight: According to recent market studies, automated systems improve operational efficiency by 30-40% on average, while semi-automated machines remain the most popular choice for small businesses due to their cost-effectiveness.

2.3 Customization Options and Advanced Features

When purchasing a box wrapper, consider the level of customization required. Some advanced features that can be game-changers include:

- Pre-Stretch Film Mechanisms: Reduce film usage by up to 50%, leading to significant cost savings over time.

- Variable Wrapping Modes: Allow operators to adjust the tension, speed, and layering for different load requirements.

- IoT Connectivity: Modern machines come with IoT-enabled dashboards, providing real-time data on performance, film usage, and maintenance needs.

By investing in machines with these features, you can future-proof your operations and stay ahead of industry trends.

2.4 Dive Deeper: Understanding Total Cost of Ownership (TCO)

It’s easy to focus solely on the upfront cost of a box wrapper, but the Total Cost of Ownership (TCO) provides a more accurate picture of long-term expenses. TCO includes factors such as maintenance, energy consumption, and labor costs.

| Cost Component | Example Figures (Per Year) |

|---|---|

| Maintenance | $1,000–$3,000 |

| Energy Consumption | $500–$1,200 |

| Film Usage | $2,000–$5,000 |

Key Insight: Machines with energy-efficient motors and pre-stretch capabilities can reduce TCO by 15-20% annually.

2.5 Two Fact Statements

Fact 1 (True): Machines with pre-stretch film mechanisms can reduce film usage by up to 50%.

Fact 2 (False): Fully automated machines are always the best choice, regardless of production volume.

Explanation: While fully automated machines are ideal for high-volume operations, they may not provide the best ROI for smaller businesses with lower packaging demands.

3. Automated vs. Semi-Automated Box Wrappers: Which Is the Better Choice for Your Operations?

3.1 Automated vs. Semi-Automated: Key Differences

The choice between automated and semi-automated box wrappers often boils down to operational scale and budget. Here’s a breakdown of the main differences:

- Automated Machines: These are designed for high-speed, large-scale operations. They require minimal operator involvement, making them ideal for 24/7 production lines. However, they come with a higher initial cost and require a larger footprint.

- Semi-Automated Machines: These are more affordable and versatile, making them suitable for small to medium businesses. Operators are required to load and start the wrapping process, which adds a manual element.

3.2 Key Statistics and Comparison Table

| Feature | Automated Machines | Semi-Automated Machines |

|---|---|---|

| Production Speed | 60-80 wraps/hour | 20-30 wraps/hour |

| Operator Involvement | Minimal | Moderate |

| Upfront Cost | $25,000–$60,000 | $8,000–$20,000 |

| Best Use Cases | High-volume, consistent loads | Variable loads, limited budget |

A report by the International Packaging Association found that fully automated systems reduced labor costs by 40%, while semi-automated machines improved flexibility for SMEs by 25%.

3.3 Making the Right Choice

To determine the best option for your operations, consider the following:

- Volume and Frequency: For companies processing thousands of boxes daily, automation is a no-brainer.

- Budget Constraints: Semi-automated machines are more affordable upfront and suitable for businesses with tight capital.

- Flexibility Needs: If you frequently handle different box sizes, semi-automated machines provide better adaptability.

3.4 Dive Deeper: ROI Comparison

To understand which option offers the best return on investment (ROI), let’s explore a cost-benefit analysis for the solution in automatic box wrapping machine (in China):

| Metric | Automated Machines | Semi-Automated Machines |

|---|---|---|

| Labor Savings (Annual) | $20,000 | $8,000 |

| Film Savings (Pre-Stretch) | $1,200 | $1,000 |

| Maintenance Costs | $1,500 | $500 |

Insight: While automated machines have higher upfront costs, their ROI becomes evident in high-volume operations within 2–3 years. Conversely, semi-automated machines deliver steady savings for smaller businesses.

Two Fact Statements

Fact 1 (True): Fully automated machines can reduce labor costs by up to 40%.

Fact 2 (False): Semi-automated machines are outdated and cannot handle modern packaging demands.

Explanation: Semi-automated machines remain highly relevant due to their affordability, adaptability, and ability to handle varying load types effectively.

4. How Do Automated Box Wrappers Improve Production Efficiency and Minimize Downtime?

4.1 The Role of Automation in Modern Packaging

In the fast-paced world of manufacturing and logistics, automation has become a cornerstone of efficiency. Automated box wrappers are specifically designed to streamline operations, ensuring consistent, reliable performance with minimal manual intervention. These machines reduce errors, eliminate bottlenecks, and maximize throughput, making them indispensable for large-scale operations.

Companies that rely on automated box wrappers often experience:

- Faster Turnaround Times: Automated systems can handle up to 80 wraps per hour, significantly outpacing manual or semi-automated solutions.

- Improved Consistency: Automation ensures uniform wrapping, reducing material waste and improving the presentation of packaged goods.

- Reduced Downtime: Advanced diagnostics and self-maintenance features minimize machine failures, keeping production lines running smoothly.

4.2 Key Statistics and Efficiency Table

To understand the impact of automated box wrappers on production efficiency, let’s look at some key data:

| Metric | Before Automation | After Automation |

|---|---|---|

| Average Wraps/Hour | 20–30 | 60–80 |

| Labor Costs (Annual) | $50,000–$70,000 | $20,000–$30,000 |

| Material Waste | ~15% | ~5% |

| Downtime (Hours/Month) | 20–30 | 5–10 |

Key Insight: According to a study by the Packaging Industry Association, companies using automated systems report a 30–40% increase in operational efficiency and a 50% reduction in material waste.

4.3 Common Causes of Downtime and How Automation Solves Them

Downtime in packaging operations can be costly, both in terms of lost productivity and delayed shipments. Here’s how automation addresses common issues:

- Operator Fatigue: Manual processes are prone to errors and delays due to physical strain on workers. Automated systems eliminate this issue entirely.

- Machine Malfunctions: Modern automated machines come equipped with predictive maintenance features, using sensors and IoT connectivity to identify potential problems before they cause breakdowns.

- Inconsistent Wrapping: Automation ensures that every box is wrapped to the same standard, reducing the need for rework and saving time.

By addressing these issues, automated box wrappers not only improve efficiency but also enhance the overall reliability of packaging operations.

4.4 Dive Deeper: Long-Term Benefits of Automated Systems

Beyond immediate improvements in speed and consistency, automated box wrappers provide several long-term benefits:

- Scalability: As your business grows, automated systems can easily handle higher volumes without the need for additional labor.

- Data-Driven Insights: IoT-enabled machines provide real-time data on performance metrics, helping you identify inefficiencies and optimize processes.

- Lower Operational Costs: Over time, the savings in labor, materials, and downtime offset the higher upfront cost of automation.

| Cost Savings (Over 5 Years) | Amount |

|---|---|

| Labor Cost Reduction | $150,000–$250,000 |

| Material Waste Reduction | $30,000–$50,000 |

| Downtime Reduction | $20,000–$40,000 |

Insight: Fully automated systems typically pay for themselves within 2–4 years, making them a smart investment for high-volume operations.

4.5 Two Fact Statements

Fact 1 (True): Automated box wrappers can increase operational efficiency by up to 40%.

Fact 2 (False): Automated systems are only beneficial for large-scale operations and provide no value to smaller businesses.

Explanation: While automation is ideal for large-scale operations, smaller businesses can also benefit by reducing reliance on labor and improving packaging consistency, especially if they plan to scale in the future.

5. What Are the Key Considerations When Contacting Box Wrapping Machine Providers?

5.1 Choosing the Right Partner

Selecting the right box wrapping machine provider is just as important as choosing the machine itself. A reliable provider can offer expert guidance, ongoing support, and access to the latest technology. Here’s what to look for in a provider:

- Industry Experience: Choose a provider with a proven track record in your industry to ensure they understand your specific needs.

- Comprehensive Support: Look for providers that offer installation, training, and maintenance services to maximize the lifespan of your machine.

- Customization Options: A good provider should offer machines with customizable features to suit your unique operational requirements.

- Warranty and After-Sales Service: Ensure the provider offers a robust warranty and responsive after-sales support to address any issues that may arise.

5.2 Key Provider Selection Data

Let’s break down the key factors to consider when evaluating providers:

| Factor | What to Look For |

|---|---|

| Experience | 10+ years in the packaging industry |

| Warranty Terms | 2–5 years, covering parts and labor |

| After-Sales Support | 24/7 helpline, on-site repairs |

| Customization Options | Tailored solutions for unique packaging needs |

Key Insight: According to a survey by Packaging World, 75% of buyers cite after-sales support as the most critical factor when choosing a machine provider.

5.3 Dive Deeper: Questions to Ask Providers

To ensure you’re making the right choice, ask potential providers the following questions:

- What safety certifications do your machines have?

- How long is the average lead time for delivery and installation?

- What training programs do you offer for operators?

- Can you provide references or case studies from similar industries?

- What is included in your maintenance and repair packages?

By asking these questions, you can identify providers who are committed to delivering value beyond just the machine itself.

5.4 Negotiating Terms with Providers

Once you’ve shortlisted potential providers, it’s time to negotiate terms. Focus on securing favorable conditions for:

- Warranty: Aim for at least a 3-year warranty that covers both parts and labor.

- Maintenance Plans: Negotiate for discounted or complimentary maintenance services for the first year.

- Delivery and Installation: Ensure that these costs are included in the quoted price.

| Negotiation Priority | Recommended Terms |

|---|---|

| Warranty | 3–5 years |

| Maintenance | 1 year free, discounted thereafter |

| Installation | Free or subsidized |

5.5 Two Fact Statements

Fact 1 (True): Providers with strong after-sales support can reduce machine downtime by up to 30%.

Fact 2 (False): The most expensive providers always offer the best machines and services.

Explanation: Price isn’t always an indicator of quality. Focus on the provider’s reputation, experience, and support offerings to ensure long-term value.

6. How Can You Negotiate the Best Price for a Box Wrapper Without Compromising Quality?

6.1 The Importance of Price Negotiation

Investing in a box wrapper is a significant financial decision, and effective negotiation can help you secure the best price without sacrificing quality. Many buyers assume that the listed price is final, but providers are often willing to adjust costs based on volume, long-term partnerships, or added services. Successful negotiation requires understanding the market, knowing your priorities, and approaching the process strategically.

Key elements to focus on include:

- Volume Discounts: Larger orders or long-term service agreements can lead to significant savings.

- Bundled Services: Negotiate for extras like free installation, extended warranties, or operator training within the quoted price.

- Market Research: Being aware of industry pricing trends gives you leverage during discussions.

6.2 Key Data and Pricing Trends

Before entering negotiations, it’s important to understand the typical cost ranges for box wrapping machines:

| Machine Type | Price Range | Additional Costs |

|---|---|---|

| Semi-Automated Machines | $8,000–$20,000 | Installation, training |

| Fully Automated Machines | $25,000–$60,000 | Maintenance, software upgrades |

| Custom Solutions | $30,000–$80,000+ | Customization, IoT connectivity |

Pricing Insight: According to a recent industry report, buyers can save up to 15% by bundling services such as maintenance and operator training into their purchase agreements.

6.3 Strategies for Effective Negotiation

Here are some strategies to ensure you get the best deal:

- Prepare a Budget: Establish a clear budget and communicate your financial constraints to the provider.

- Request Multiple Quotes: Compare offerings from 2–3 providers to identify competitive pricing and additional services.

- Leverage Long-Term Value: Emphasize your potential as a repeat customer to negotiate better terms.

- Negotiate Beyond Price: Focus on securing value-added services like extended warranties, free installation, or discounts on future upgrades.

- Time Your Purchase Strategically: Many providers offer discounts at the end of a fiscal quarter or year to meet sales targets.

6.4 Dive Deeper: Balancing Quality and Cost

It’s tempting to prioritize upfront savings, but sacrificing quality can lead to higher costs in the long run. Here’s how to balance affordability with reliability:

- Assess Build Quality: Machines made with durable materials and high-quality components may cost more initially but require fewer repairs over time.

- Evaluate Provider Support: Choose providers with robust after-sales support to minimize downtime and maintenance expenses.

- Consider Total Cost of Ownership (TCO): While a cheaper machine may save money upfront, higher energy consumption, frequent repairs, or inefficient operation can inflate costs over its lifespan.

| Cost Comparison Over 5 Years | High-Quality Machine | Low-Cost Machine |

|---|---|---|

| Upfront Cost | $50,000 | $30,000 |

| Maintenance Costs | $5,000 | $15,000 |

| Downtime Costs | $3,000 | $10,000 |

| Total Cost | $58,000 | $55,000 |

Key Insight: While the lower-cost machine may seem like the better deal upfront, the high-quality machine delivers better long-term value due to reduced maintenance and downtime expenses.

6.5 Two Fact Statements

Fact 1 (True): Buyers can save up to 15% by negotiating bundled services like training and maintenance.

Fact 2 (False): The lowest-priced machine always offers the best value for money.

Explanation: The lowest-priced option may lack key features, durability, or after-sales support, which could lead to higher long-term costs. Focus on balancing upfront costs with overall value.

7. What Real-World Case Studies Showcase the Success of Box Wrappers in Similar Operations?

7.1 Learning from Industry Success Stories

Real-world case studies provide valuable insights into how box wrappers can transform packaging operations. They highlight the tangible benefits, from improved efficiency to reduced costs, and offer lessons that can be applied to your own business.

Example industries that have successfully implemented box wrappers include:

- E-Commerce Fulfillment Centers: Automated systems that handle high volumes of standardized packages.

- Food and Beverage Manufacturers: Machines with customizable settings to wrap delicate or perishable items.

- Logistics and Warehousing: Versatile machines that accommodate a variety of box sizes and shapes.

7.2 Case Study 1: E-Commerce Fulfillment Center

Problem: A leading e-commerce company struggled with delayed shipments and damaged packages due to inconsistent manual wrapping.

Solution: The company invested in fully automated box wrappers with IoT connectivity to monitor performance.

Results:

| Metric | Before | After |

|---|---|---|

| Average Packages/Day | 5,000 | 8,000 |

| Package Damage Rate | 10% | 2% |

| Labor Costs (Annual) | $300,000 | $180,000 |

Key Takeaway: Automation improved efficiency by 60% and reduced labor costs by 40%, delivering a full ROI within two years.

7.3 Case Study 2: Food and Beverage Manufacturer

Problem: A food manufacturer faced high material waste and frequent machine malfunctions with their outdated box wrapping system.

Solution: They replaced their old equipment with a semi-automated system featuring pre-stretch film technology and advanced diagnostics.

Results:

| Metric | Before | After |

|---|---|---|

| Film Waste | 20% | 5% |

| Maintenance Downtime | 25 hours/month | 8 hours/month |

| Material Costs (Annual) | $50,000 | $35,000 |

Key Takeaway: The new system reduced material waste by 75% and minimized downtime, significantly lowering operational costs.

7.4 Dive Deeper: Lessons from Case Studies

These case studies illustrate the importance of:

- Customizing Solutions: Tailoring machines to meet specific operational needs.

- Investing in Technology: Features like IoT connectivity and pre-stretch film mechanisms can deliver significant cost savings.

- Evaluating ROI: Understanding the long-term value of automation beyond the immediate cost.

7.5 Two Fact Statements

Fact 1 (True): Automated systems can reduce package damage rates by up to 80% in high-volume operations.

Fact 2 (False): Case studies only apply to large-scale businesses and are irrelevant for SMEs.

Explanation: Case studies often highlight scalable solutions that can be adapted to businesses of any size, offering valuable insights for SMEs as well.

8. Why Do Our Safety Features and Compliance Standards Make Us the Best Choice?

8.1 The Importance of Safety and Compliance

In packaging operations, safety and compliance are non-negotiable. A reliable box wrapper not only ensures smooth operations but also protects workers, minimizes accidents, and adheres to industry regulations. Machines equipped with advanced safety features and certifications reduce liability risks and demonstrate a commitment to responsible practices.

Investing in a machine designed with safety in mind delivers:

- Workplace Safety: Reducing injuries caused by manual wrapping or inadequate equipment.

- Regulatory Compliance: Meeting industry and legal standards to avoid fines or operational shutdowns.

- Reputation Management: Demonstrating responsibility increases trust among employees and stakeholders.

8.2 Key Compliance Data and Safety Features

Let’s explore the most critical compliance standards and safety features in the box wrapping industry:

| Compliance Standard | Description | Benefit |

|---|---|---|

| ISO 13849 | Ensures safety-related machine parts are reliable | Reduces the risk of malfunctions |

| CE Marking | Certifies compliance with EU safety standards | Legal operation in European markets |

| OSHA Standards | Protects workers from machinery hazards | Minimizes workplace injuries |

| ANSI B11 | U.S. safety standards for industrial machinery | Ensures safe machine operation |

Top Safety Features to Look For:

- Emergency Stop Buttons: Allows operators to stop the machine immediately during malfunctions.

- Load Stability Detectors: Prevents improper wrapping that could lead to accidents or product damage.

- Safety Guarding: Shields moving parts to reduce the risk of operator injury.

- User-Friendly Interfaces: Intuitive controls reduce human error.

8.3 Real-World Impact of Compliance

Non-compliance can lead to severe consequences, including fines, lawsuits, and reputational damage. Conversely, adhering to safety standards provides measurable benefits:

| Metric | Before Compliance | After Compliance |

|---|---|---|

| Workplace Injuries/Year | 15+ | <5 |

| Downtime Due to Accidents | 10+ hours/month | <2 hours/month |

| Legal/Regulatory Fines | $20,000+ | $0 |

Insight: A survey by the International Labor Organization found that companies with certified safety equipment report 70% fewer workplace injuries and significantly lower downtime.

8.4 Dive Deeper: Why We’re the Industry Leader

Our box wrappers are designed with cutting-edge safety and compliance features, making us the preferred choice for businesses of all sizes. Here’s what sets us apart:

- Proactive Compliance: All our machines meet or exceed ISO, CE, OSHA, and ANSI standards, ensuring legality and safety in any market.

- Advanced Safety Engineering: From load stability detectors to ergonomic designs, our machines prioritize operator safety.

- Comprehensive Training: We offer on-site training programs to ensure your team operates the machines safely and effectively.

- Focus on Sustainability: Our machines not only meet safety standards but are also designed to minimize environmental impact, aligning with global ESG (Environmental, Social, Governance) goals.

By choosing us, you’re investing in much more than a machine—you’re ensuring safe, efficient, and compliant operations.

8.5 Two Fact Statements

Fact 1 (True): Machines with CE certifications meet European safety, health, and environmental standards.

Fact 2 (False): Safety compliance is only necessary for large-scale businesses.

Explanation: Safety compliance is critical for businesses of all sizes. Even small-scale operations must adhere to safety and regulatory requirements to protect employees and avoid penalties.

9. Which Contract Clauses Ensure Long-Term Performance and Low Maintenance Costs for Box Wrappers?

9.1 The Importance of a Detailed Contract

A detailed contract is essential when purchasing a box wrapper. It ensures that your investment is protected and that both parties are accountable for the machine's performance and maintenance. Without a comprehensive agreement, you may face unexpected expenses or inadequate service.

Key clauses to include in your contract:

- Warranty Terms: Covers parts and labor for a specified period, protecting against manufacturing defects.

- Service Agreements: Outlines the frequency of maintenance visits and what they include.

- Performance Guarantees: Ensures the machine meets agreed-upon performance standards.

- Response Times: Specifies how quickly the provider must address maintenance or repair requests.

9.2 Key Data on Contract Benefits

A well-structured contract can save significant costs over the lifespan of your machine:

| Clause | Potential Savings |

|---|---|

| Warranty (3–5 years) | $5,000–$10,000 |

| Preventive Maintenance | $2,000–$4,000 annually |

| Downtime Reduction | $3,000–$6,000 annually |

Key Insight: According to a survey by Packaging World, 85% of buyers report fewer breakdowns and lower maintenance costs when they secure a robust service agreement in their contracts.

9.3 Essential Clauses to Negotiate

Here’s what to prioritize during contract negotiations:

- Comprehensive Warranty: Covers both parts and labor for a minimum of 3 years.

- Preventive Maintenance Plans: Includes routine checks to identify and address issues before they become major problems.

- Guaranteed Performance: Ensures the machine operates at specified speeds and efficiency levels.

- Upgrade Discounts: Provides reduced rates for future software or hardware upgrades.

- Service Response Times: Guarantees repairs within 24–48 hours to minimize downtime.

9.4 Dive Deeper: Long-Term Impact of Contracts

A strong contract doesn’t just protect you financially; it also ensures long-term performance and reliability. Here’s what you gain:

- Predictable Costs: Fixed maintenance fees reduce the risk of unexpected expenses.

- Increased Machine Lifespan: Regular servicing ensures optimal performance for years.

- Faster Repairs: Clear response time clauses minimize downtime during repairs or part replacements.

| Impact Over 5 Years | With Contract | Without Contract |

|---|---|---|

| Downtime Costs | $2,000/year | $5,000/year |

| Maintenance Costs | $2,500/year | $5,000/year |

| Total Costs | $22,500 | $40,000 |

Insight: Securing a detailed contract can reduce total ownership costs by 40% over five years, making it a critical step in your purchase process.

9.5 Two Fact Statements

Fact 1 (True): A well-negotiated service agreement can reduce downtime costs by up to 50%.

Fact 2 (False): Contracts are only necessary for machines with a high upfront cost.

Explanation: Regardless of the machine’s price, a detailed contract ensures that you’re protected from unexpected expenses and performance issues, making it essential for all purchases.

10. What Negotiation Strategies Can Help You Secure Favorable Warranty Terms for Your Box Wrapper?

10.1 The Value of Warranty in Long-Term Performance

A strong warranty is a key part of any box wrapper purchase. It provides financial protection, ensures peace of mind, and guarantees support in case of malfunctions or manufacturing defects. Securing favorable warranty terms requires strategic negotiation, as providers may initially offer limited coverage.

Key benefits of a strong warranty include:

- Reduced Repair Costs: Covers expensive component replacements and labor.

- Extended Machine Lifespan: Encourages regular maintenance, reducing wear and tear.

- Increased Resale Value: Machines with transferable warranties retain higher resale value.

10.2 Common Warranty Terms

When negotiating a warranty, it’s important to understand the standard terms offered in the industry:

| Warranty Component | Typical Coverage | Ideal Coverage |

|---|---|---|

| Duration | 1–2 years | 3–5 years |

| Parts Coverage | Major components only | All components, including wear parts |

| Labor Coverage | Limited or excluded | Full labor costs included |

| Exclusions | Operator errors, misuse | Limited exclusions |

Key Insight: According to a report from Automation World, machines with warranties of 3+ years deliver 30% lower maintenance costs during their lifespan compared to those with shorter coverage.

10.3 Negotiation Strategies for Better Warranty Terms

Here are proven strategies to secure favorable warranty terms:

- Leverage Competitor Offers: Show the provider competing offers with better warranty terms to encourage them to match or exceed the coverage.

- Bundle Warranty with Maintenance Plans: Providers are often willing to extend warranties if you agree to purchase a preventive maintenance plan.

- Highlight Long-Term Partnership Potential: Emphasize your intent for repeat business or future upgrades to incentivize better terms.

- Request Extended Coverage for Wear Parts: These components are often excluded but can lead to significant repair costs over time.

- Negotiate Transferability: If you plan to resell the machine, ensure the warranty can transfer to the new owner to increase resale value.

10.4 Dive Deeper: Structuring the Optimal Warranty

To maximize the value of your warranty, focus on securing these key elements:

- Comprehensive Coverage: Ensure all critical components, including wear parts, are included.

- No Hidden Costs: Verify that labor and technician travel expenses are covered.

- Clear Response Times: Specify how quickly the provider must respond to warranty claims.

- Preventive Maintenance Tie-In: Negotiate for discounted or included maintenance services during the warranty period.

| Example Warranty Comparison | Standard Warranty | Negotiated Warranty |

|---|---|---|

| Duration | 2 years | 5 years |

| Wear Parts Coverage | Excluded | Included |

| Labor Costs | Excluded | Fully Covered |

| Response Time | 72 hours | 24–48 hours |

Key Insight: A well-negotiated warranty can reduce repair costs by 50% over the machine’s lifespan, making it an essential part of the purchasing process.

10.5 Two Fact Statements

Fact 1 (True): Machines with warranties of 3+ years have 30% lower maintenance costs over their lifespan.

Fact 2 (False): Wear parts are always covered under the standard warranty terms.

Explanation: Wear parts, such as belts and rollers, are often excluded from standard warranties. Including them in your negotiated terms can save significant repair costs.

11. What Real-World Contract Clauses and Negotiation Results Have Proven Successful?

11.1 Why Contract Clauses and Negotiations Matter

Well-structured contracts and effective negotiations ensure that your investment in a box wrapper delivers maximum returns. Real-world examples demonstrate how businesses have successfully negotiated terms that minimize costs, maximize machine performance, and reduce risks.

Key focus areas include:

- Warranty Extensions: Negotiating longer warranty durations for better protection.

- Upfront Discounts: Securing lower prices through volume purchases or bundled services.

- Maintenance Guarantees: Locking in service schedules and response times to reduce downtime.

11.2 Case Study 1: A Logistics Company’s Success

Problem: A global logistics company experienced frequent downtime due to poor warranty coverage and slow provider response times.

Negotiation Approach:

- Bundled a preventive maintenance plan with a 5-year extended warranty.

- Secured a 48-hour response time clause for warranty claims.

Results:

| Metric | Before Negotiation | After Negotiation |

|---|---|---|

| Warranty Duration | 2 years | 5 years |

| Downtime Costs | $6,000/year | $2,000/year |

| Annual Maintenance Costs | $4,000 | $2,500 |

Key Takeaway: Proactive negotiation reduced downtime costs by 66% and maintenance costs by 38%, delivering a significant ROI.

11.3 Case Study 2: A Manufacturing Firm’s Volume Discount

Problem: A mid-sized manufacturing firm needed five fully automated box wrappers but struggled to justify the high upfront cost.

Negotiation Approach:

- Requested a volume discount for purchasing five machines simultaneously.

- Secured free installation, training, and a 3-year maintenance plan as part of the deal.

Results:

| Metric | Before Negotiation | After Negotiation |

|---|---|---|

| Upfront Cost (Per Machine) | $50,000 | $42,000 |

| Installation Costs | $5,000 | $0 |

| Training Costs | $3,000 | $0 |

Key Takeaway: The firm saved over $45,000 through volume discounts and bundled services, making the investment more affordable.

11.4 Dive Deeper: Lessons from Real-World Negotiations

Here’s what these case studies teach us:

- Be Prepared to Walk Away: Showing that you’re willing to explore other providers can strengthen your negotiating position.

- Focus on Total Value, Not Just Price: Bundling services and securing extended warranties often delivers better long-term savings than simply negotiating a lower price.

- Leverage Timing: Providers are more likely to offer discounts or favorable terms near the end of fiscal periods to meet sales targets.

By applying these lessons, you can maximize the value of your purchase while minimizing risks and costs.

11.5 Two Fact Statements

Fact 1 (True): Volume purchases can reduce per-machine costs by up to 15%.

Fact 2 (False): Providers rarely negotiate warranty terms or additional services.

Explanation: Providers are often open to negotiating warranty terms, service bundles, and other add-ons as part of the sales process, especially for large or repeat customers.

12. Conclusion: Making the Right Investment in a Box Wrapper

Investing in the right box wrapping machine is about more than just purchasing equipment—it’s about improving efficiency, ensuring safety, reducing operational costs, and preparing your business for long-term growth. By carefully evaluating your operational needs, understanding the available options, and negotiating favorable terms, you can maximize the value of your investment.

Here’s a summary of the key takeaways from this guide:

12.1 Key Takeaways to Remember

-

Safety First:

- Prioritize machines with advanced safety features like emergency stop buttons, guarding systems, and load stability detectors.

- Ensure compliance with certifications such as ISO 13849, CE Marking, OSHA, and ANSI B11 standards.

-

Choosing the Right Machine:

- Fully automated systems are ideal for high-volume, standardized operations.

- Semi-automated machines are cost-effective for SMEs or operations with variable load sizes.

- Consider Total Cost of Ownership (TCO), not just the upfront price, to understand long-term costs.

-

Leveraging Automation:

- Automation improves production efficiency by up to 40% and reduces material waste by 50%.

- IoT-enabled machines provide real-time monitoring for maintenance and performance optimization.

-

Negotiation Strategies:

- Focus on securing favorable warranty terms (3–5 years), bundled services, and discounted maintenance plans.

- Leverage volume purchases or long-term partnerships to negotiate better pricing and additional benefits.

-

The Role of Contracts:

- Ensure contracts include comprehensive warranty coverage, preventive maintenance plans, and performance guarantees.

- Specify response times for repairs and service to minimize downtime.

-

Real-World Success:

- Case studies show that businesses can reduce downtime costs by 66% and achieve ROI within 2–3 years by investing in the right box wrapper.

12.2 Steps to Take Before Purchasing

To ensure your investment delivers maximum value, follow these steps:

-

Assess Your Needs:

- Determine your production volume, load types, and packaging goals.

- Decide between fully automated and semi-automated systems based on your budget and scalability plans.

-

Research Providers:

- Choose a provider with a proven track record, strong after-sales support, and a focus on compliance.

- Request multiple quotes to compare pricing, services, and warranty terms.

-

Negotiate Strategically:

- Don’t settle for the initial offer—negotiate for bundled services, extended warranties, and reduced costs.

- Emphasize your potential as a long-term partner to secure better terms.

-

Finalize a Detailed Contract:

- Ensure the contract includes all negotiated terms, clear service agreements, and warranty details.

- Review the contract carefully to avoid hidden fees or exclusions.

-

Plan for Training and Maintenance:

- Schedule operator training to ensure safe and efficient use of the machine.

- Set up a preventive maintenance plan to maximize machine lifespan and minimize downtime.

12.3 Why Choosing the Right Partner Matters

The right provider is more than just a seller—they’re a partner in your success. By working with a reliable provider, you can:

- Access expert guidance to select the best machine for your needs.

- Receive ongoing support to keep your operations running smoothly.

- Stay ahead of industry trends with access to the latest technology.

Key Insight: A trusted provider ensures that your investment delivers long-term value, reducing risks and improving overall business performance.

12.4 Final Thought

A box wrapping machine is not just a piece of equipment—it’s a strategic tool that can transform your packaging operations, enhance productivity, and support your growth goals. By making an informed decision and focusing on long-term value, you can ensure that your investment delivers measurable returns for years to come.