Home > Products > Show Room > Box Wrapper >

Fhopepack Innovation

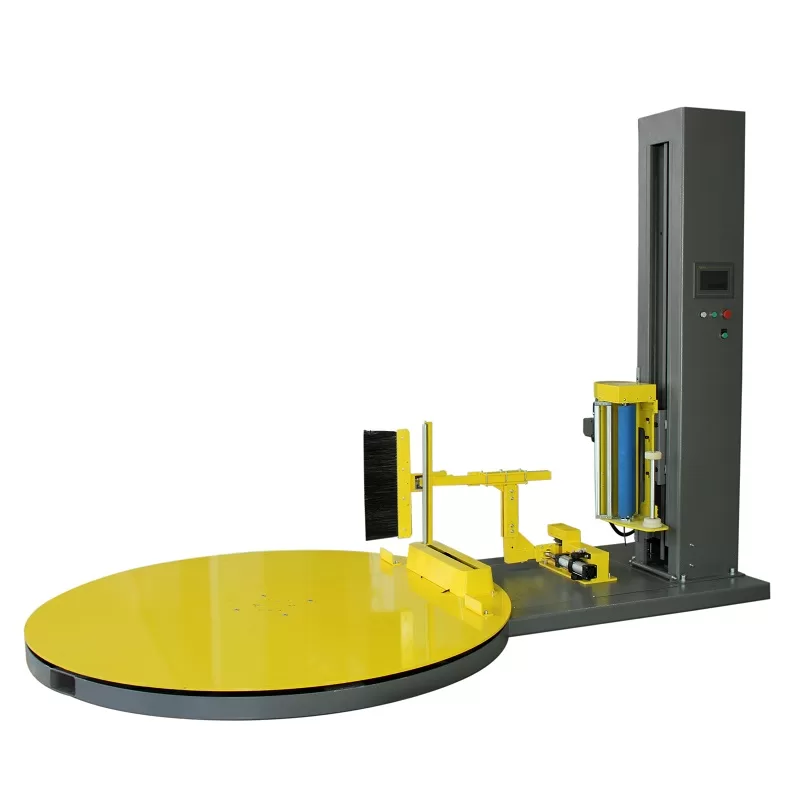

Box Pallet Wrapper

The Box Pallet Wrapper is a versatile packaging solution designed for secure and efficient wrapping of box pallets. It features advanced controls, adjustable pre-stretch ratios, and robust safety mechanisms. Built with durable materials, it ensures stability and adaptability, making it ideal for diverse industrial and logistical applications.