Home > Products > Show Room > Box Wrapper >

Fhopepack Innovation

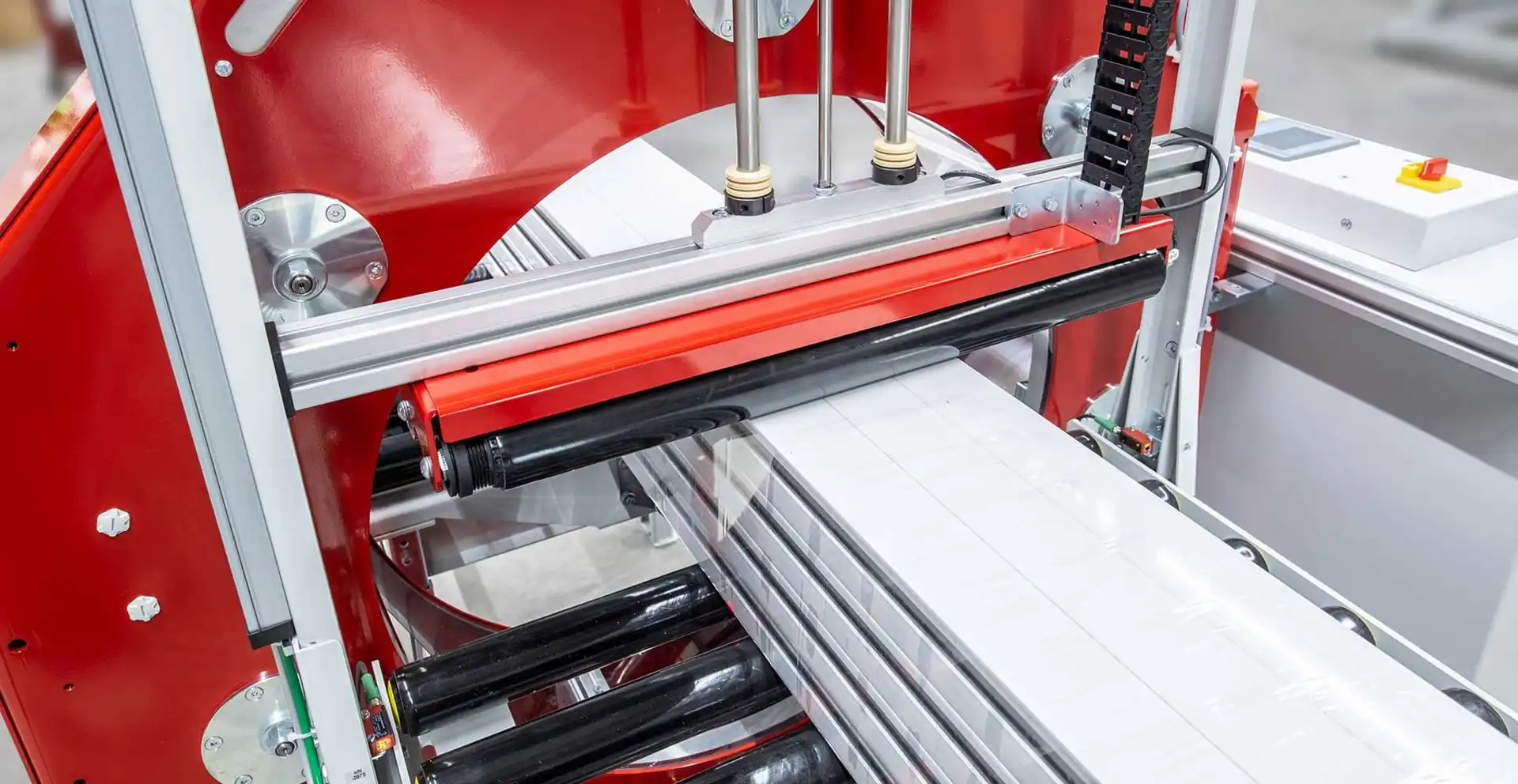

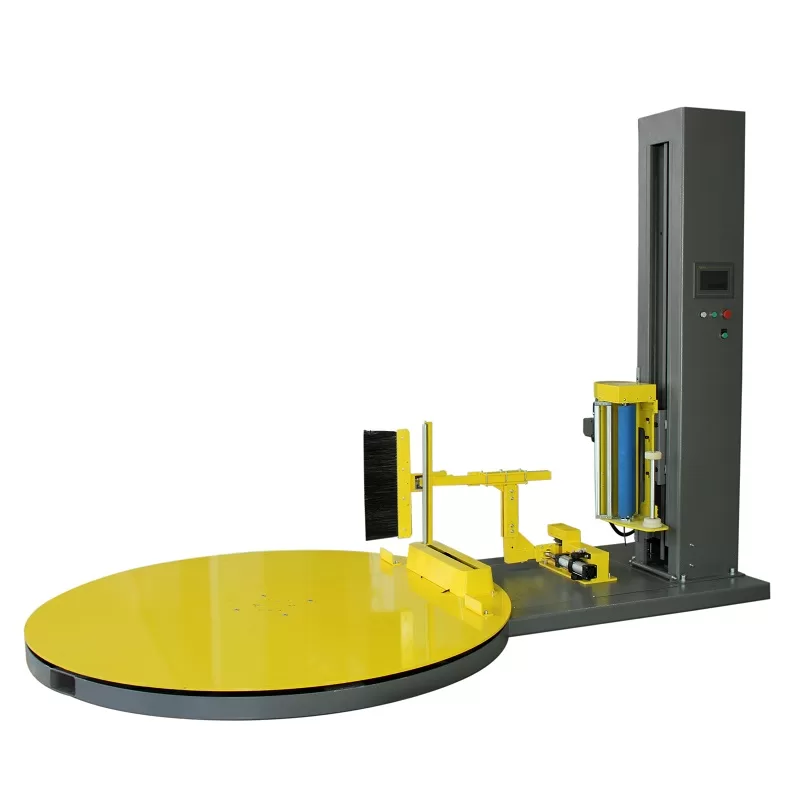

Box Horizontal Wrapper

The Box Horizontal Wrapper is a cutting-edge machine tailored for efficient and secure packaging of boxes. It streamlines operations, minimizes material usage, and delivers uniform wrapping results. Perfect for high-volume industries, it combines reliability, speed, and versatility to meet diverse packaging requirements seamlessly.