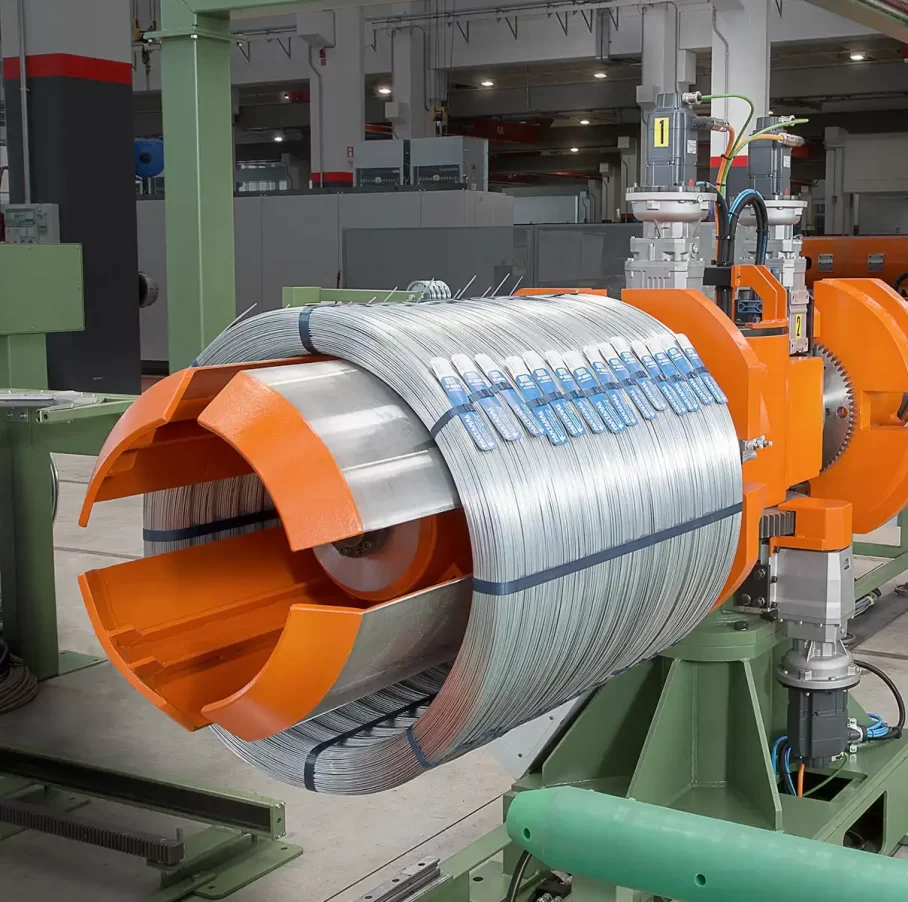

Automatic Wire Winding And Packing Machine

The automatic wire winding and packaging machine is the packing line to help changing the the big wire reel into small wire coil per different packaging way.

It is an offline system for payoff the steel wire reel for re-widning, length checking, wrapping, strapping...

The automation solution is able checking the wire weight, printing, wire information checking and tracking. And all information can be transfer to the MES by ERP system.

FHOPE providing the automatic rewinding and packing line for changing the steel wire from reel and spool into small size per weight. The wire coil be binding by steel wire, strapping by PET or PE...

Now many steel wire drawing factory using manually or semi auto equipment in steel wire rewinding and packaging. That includes different machine from different supplier. And the wire coil handling from one machine to another is a problem too. The wire wind and packing line provided by FHOPE integrated the wire production and packing machinery together to help the wire manufacturer improving the wire procession and handling from the production line. Only one man required for monitor the system offered by FHOPEPACK.

Automatic Wire Winding and Packing Machine

-

Steel wire winding and wrapping machineSteel wire winding and wrapping machine is a comprehensive solution that includes both a steel wire rewinding machine and a wire coil wrapping machine. After the wire coil is wound, it is automatically moved into the wrapping machine for film wrapping and paper packing. The stacked wire coil can then be easily unloaded using a fo...

-

Automatic steel wire winder and strapping machineAutomatic steel wire winder and strapping machine offers a convenient and efficient solution for coiling and strapping steel wire online. This machine allows for automatic coiling of single wire coils, which can then be gathered and strapped into larger bundles. Say goodbye to manual labor and hello to our state-of-the-art techno...

-

Automatic steel wire winding and binding machineChinese Manufacturer offers an automatic steel wire winding and binding machine that provides efficient steel wire rewinding and binding for packing purposes. This machine can use steel wire, PET, or PP as binding material, depending on the weight of the wire coil. Trust our state-of-the-art technology to wind and bind your steel...

-

Automatic steel wire winder and packing lineSteel wire winder and packing line is fully automated and designed to wind wire coils with an outer diameter of 400-700 mm. This system includes one packing machine that can service 2-6 winders, making it an efficient and cost-effective solution for your wire winding needs....

WHAT SHOULD YOU KNOW ABOUT THE AUTOMATIC WIRE WINDING AND PACKING MACHINE?

1. What Is an Automatic Wire Winding and Packing Machine, and Why Is It Important?

An automatic wire winding and packing machine is a specialized piece of equipment designed to streamline the process of coiling, winding, and packaging wires, cables, or hoses. These machines are widely used in industries such as electrical manufacturing, telecommunications, and automotive production.

IThe machine automates the traditionally labor-intensive process of winding wires into uniform coils and securely packing them for transportation or storage. By eliminating manual handling, an automatic wire winding and packing machine improves efficiency, reduces production time, and ensures consistency in coil quality. For high-volume manufacturing operations, this equipment is essential for meeting production demands while minimizing labor costs and reducing the risk of product damage.

Key statistics:

Whether your operation handles thin wires or heavy-duty cables, this machine ensures precise winding and professional-quality packaging, making it a crucial investment for modern manufacturing facilities.

Feel free contact us at any time.

2. What Features Should You Look for in an Automatic Wire Winding and Packing Machine?

WBy evaluating these features, you can select a machine that meets your production goals while enhancing efficiency and packaging quality.

Feel free contact us at any time.

3.What Are the Benefits of Using an Automatic Wire Winding and Packing Machine?

Investing in an automatic wire winding and packing machine provides several advantages for manufacturing operations:

For example, companies using automated winding machines report 20%-30% reductions in labor costs and 50% faster production cycles. These machines are indispensable for keeping up with high-volume demand while maintaining quality and safety standards.

Feel free contact us at any time.

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635