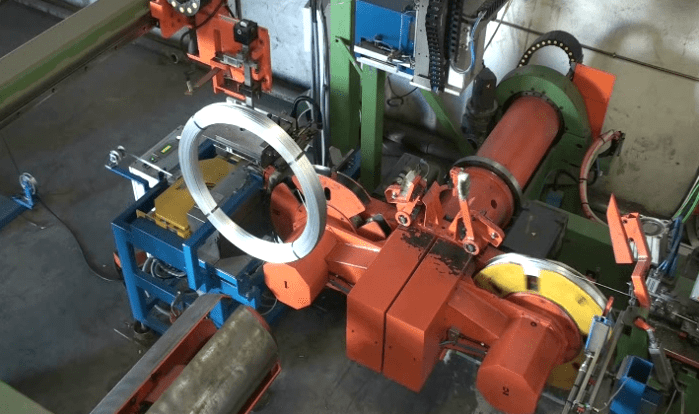

Automatic steel wire winder and strapping machine

Application:

This is an Automatic steel wire coiling and strap packing line which mainly used for steel wire winding and coil strapping. This packaging scheme adopt the latest technology and design concept with all the CE standards. It’s the current steel wire industry advanced packaging technology. FHOPE team designs and produces fully automated turnkey packaging solutions for the steel wire industry. FHOPE team be committed to continuous innovation, design and create the most efficient machine development, to solve the problems of manpower shortage and saving packaging costs. FHOPE Group's sales department, design team, quality department and after-sales department be ready to help you design the best fully automated packaging system.

Main technology parameter and components

A. Vertical tension wire accumulator

Vertical wire storage tension be assembled and welded by steel plate. The tension in operation be adjusted by control cabinet DC-24V power supply. Cumulative wire length be 5m-20m. Adopt deceleration motor, instrument display tension, automatically control the speed of running, to avoid over tension or wire broken.Multiple limit switches be used to ensure safety. Machine stop in emergency when wire be broken.

B. Automatic Coiling Machine

PLC store wire specifications, when specifications be unchanged, only the stored specifications can be read. Double winding head to achieve non-stop working. Coiling system can complete automatic wire feeding, winding coil making, cutting off wire automatically.

Automatic alarm system be working when abnormal occurs during running.

Servo motor control transverse movement, linkage with the coiling machine, HMI touch screen, operation panel with speed control button, emergency switch and so on...

Coiling Machine details:

(1): Length meter counter:

Automatic up&down adjustable for encoder reel, it can provide accurate counting length to centimeters. Upper and lower wheels be sprayed with aluminum alloy material,the lower wheels be coated with strong PU to prevent the deformation and damage of wire, be made of ceramic and hardness treatment.

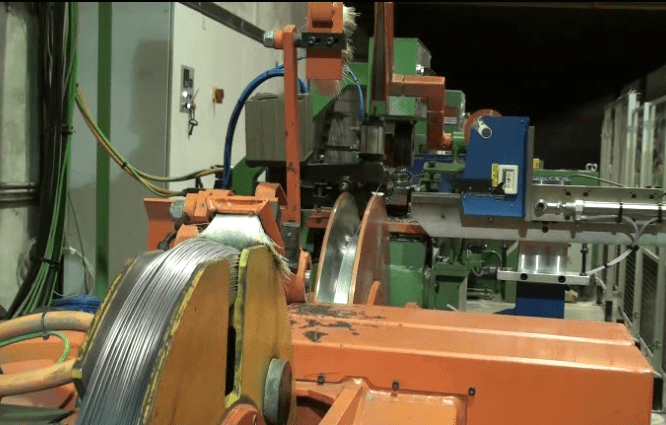

(2).Winder head:

Automatic wire feeding&clamping and automatic start coiling making. Servo control arranging system be used to control coil shape. Nose be precisely positioned for start and stop and coil strapping positioning. When predetermined length be reached, stop automatically and coiling head opens automatically.

(3) .Traverse:

(4) Be for shifting winder, servo motor drives and computer control traverse.

(5)

(6) Portal cutter:

(7) Cutter be made of special steel and processed by vacuum heating, with higher hardness and long service life. Door cutting machine design, when the bobbin reaches a predetermined length automatically cut off the wire.

C. Automatic coil strapping machine

When coil be moved to strapping position, strapping device tighten and seal the PP belt. Automatically adjust tension to ensure safe hot welding at strapping positions.

Features:

1.Through wire coil ID for strapping.

2.PLC program control for coiling and strapping steps.

3.Automatic positioning for straps strapping.

4. Adjustable tension for different wire coil size.

5. 3-6 places per coil for strapping.

Technical date:

Strap width 10mm

Strap thickness 0.8 mm

Type of strap PP belt

Strap quality Smooth /High quality polyester strap

Type of joint By friction - vibration

Joint location The strapping is performed in the front part of the wire coil.

Joint efficiency Approx. 75-90% of the breaking load of the strap.

Strapping machine be designed to achieve a high success rate of PP belt strapping,wire coil positioning, automatically perform all the strapping actions. The belt distributor and accumulator be placed in a fixed position, too easy to operate it.

D. Automatic wire coil unloading machine

Automatic device that automatically takes coil from strapping position for wire coils stacking for pallet unloading. Automatic program control to keep crane and guide rail run smoothly, to complete the last step of whole automation packaging line.