Home > Industry Machines > Other > solution >

Fhopepack Innovation

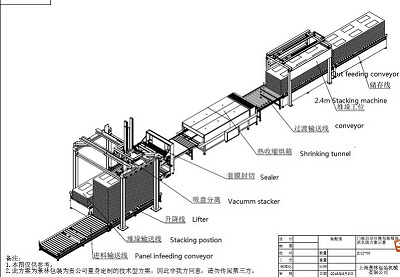

Automatic Board packaging machinery/Board shrink wrapping machine-

FPSH-B100 is a automatic shrinking machine for profile, board, window, door...with one side sealing and full sides packaging,... which is with highly efficiency and nice packaging for saving labor and material cost.