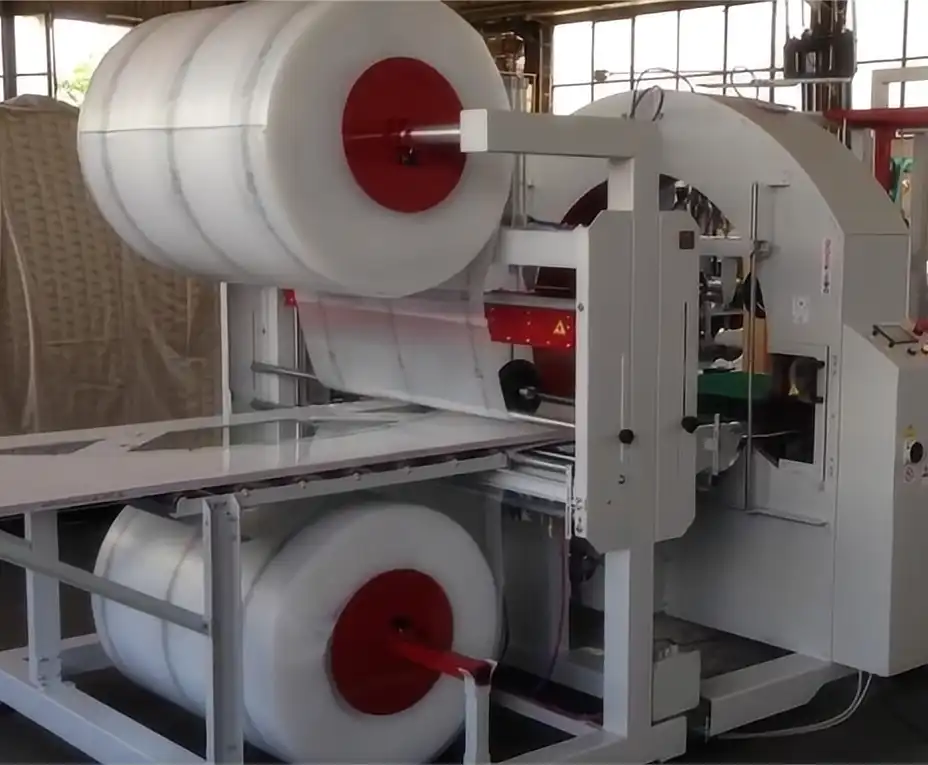

Door Horizontal Orbital Wrapping Machine: A Comprehensive Packaging Solution

The Door Horizontal Orbital Wrapping Machine is a versatile and efficient packaging solution designed for doors, panels, and other horizontal objects. Equipped with advanced features and robust construction, this machine offers precise, secure, and high-quality packaging that enhances product protection during storage and transportation.

Key Features of the Horizontal Orbital Wrapping Machine

The Door Horizontal Orbital Wrapping Machine provides an automated packaging process that uses stretch film to wrap products tightly and uniformly. The machine ensures that products are well protected, with packaging that is both neat and professional in appearance. Some of its key features include:

Reinforced Wrapping Ring:

1.The wrapping machine uses a solid aluminum cast ring to create a stable and steady wrapping operation. The ring is supported by four PU wheels, ensuring smooth motion during the wrapping process.

2.The machine’s ring speed is adjustable, allowing customization for different products and packaging requirements. This feature, combined with the friction adjustment between the driving wheels and ring, ensures optimal performance.

Versatile Wrapping Capabilities:

1.The machine is suitable for packaging a variety of horizontal objects, including doors, aluminum profiles, sheets, and furniture. The wrapped packages are not only well-protected but also visually appealing, with smooth and uniform film coverage.

2.This machine can be integrated into existing production lines, enabling fully automated packaging processes.

Adjustable Settings for Precision Wrapping:

1.The overlapping rate of the wrapping film can be adjusted from 10% to 90%, depending on the product’s packaging requirements. This level of flexibility ensures that the machine can meet different industry standards and customer specifications.

2.The start and stop points of the wrapping process can be customized via the touch screen interface, allowing operators to control the wrapping length and film tension with precision.

Advanced Control and Automation

The Door Horizontal Orbital Wrapping Machine is equipped with a sophisticated PLC control system that automates the entire packaging process, ensuring efficiency and consistency. Key features of the control system include:

-

Photocell Sensors: The machine uses photocell sensors to detect product positions accurately, ensuring proper alignment and wrapping.

-

Fully Automated Operation: Once the product is loaded onto the in-feeding conveyor, the machine takes over, wrapping the product automatically and stopping at preset positions.

Technical Specifications

The Door Horizontal Orbital Wrapping Machine comes with the following technical parameters:

Object Size:

|

|

Length:

|

2000-13,500mm

|

Width:

|

400mm

|

Height:

|

1000-200mm

|

Weight:

|

50-300kg

|

Conveyor Dimensions:

|

|

Length:

|

6000mm

|

Width:

|

1300mm

|

Wrapping Film:

|

|

Material:

|

LLDPE stretch film

|

Film Width:

|

500mm

|

Outer Diameter:

|

100-180mm

|

Inner Diameter:

|

76mm

|

Power Consumption:

|

|

Machine:

|

1.5kW

|

Conveyor:

|

0.75kW per set

|

Ring Speed:

|

10-50r/min (adjustable)

|

Wrapping Speed:

|

3-20 meters per minute

|

Power Supply:

|

380V, 50Hz, 3-phase

|

Conveyor System for Heavy-Duty Operations

The machine's conveyor system is designed to handle heavy loads, making it ideal for large and heavy products such as doors. Features of the conveyor system include:

-

Heavy-Duty Rollers: The in-feeding conveyor is built to accommodate heavy products, with a load capacity of up to 3500kg.

-

Adjustable Speed: The conveyor speed can be adjusted via the touch screen to match the wrapping speed, ensuring smooth operation without any delays or interruptions.

Mechanical Hand for Automatic Material Handling

One of the standout features of the machine is its automatic mechanical hand, which operates without the need for manual intervention. Controlled by a sensor and PLC program, the mechanical hand can automatically feed and tie the wrapping material around the product. This feature significantly reduces labor costs and improves the overall efficiency of the packaging process.

Benefits of the Door Horizontal Orbital Wrapping Machine

-

Enhanced Product Protection: The machine ensures that all sides of the product are securely wrapped, providing excellent protection against dust, moisture, and other environmental factors.

-

Custom Solutions: Provides a range of models and customizable options to suit various product sizes, shapes, and packaging requirements.

-

Automated Efficiency:With its fully automated operation and minimal manual input, the machine significantly reduces labor requirements while increasing throughput.

-

Energy Efficient:The machine's energy-efficient design helps reduce operational costs, with features like soft start/stop and recirculation heating in the shrink tunnel.

Conclusion

For manufacturers looking to streamline their packaging operations while ensuring product quality and protection, the Door Horizontal Orbital Wrapping Machine is an ideal solution. With its robust construction, automated features, and versatile wrapping capabilities, it is perfectly suited for industries that require high-quality packaging for large horizontal objects. By investing in this machine, manufacturers can increase efficiency, reduce labor costs, and deliver better-packaged products to their customers.