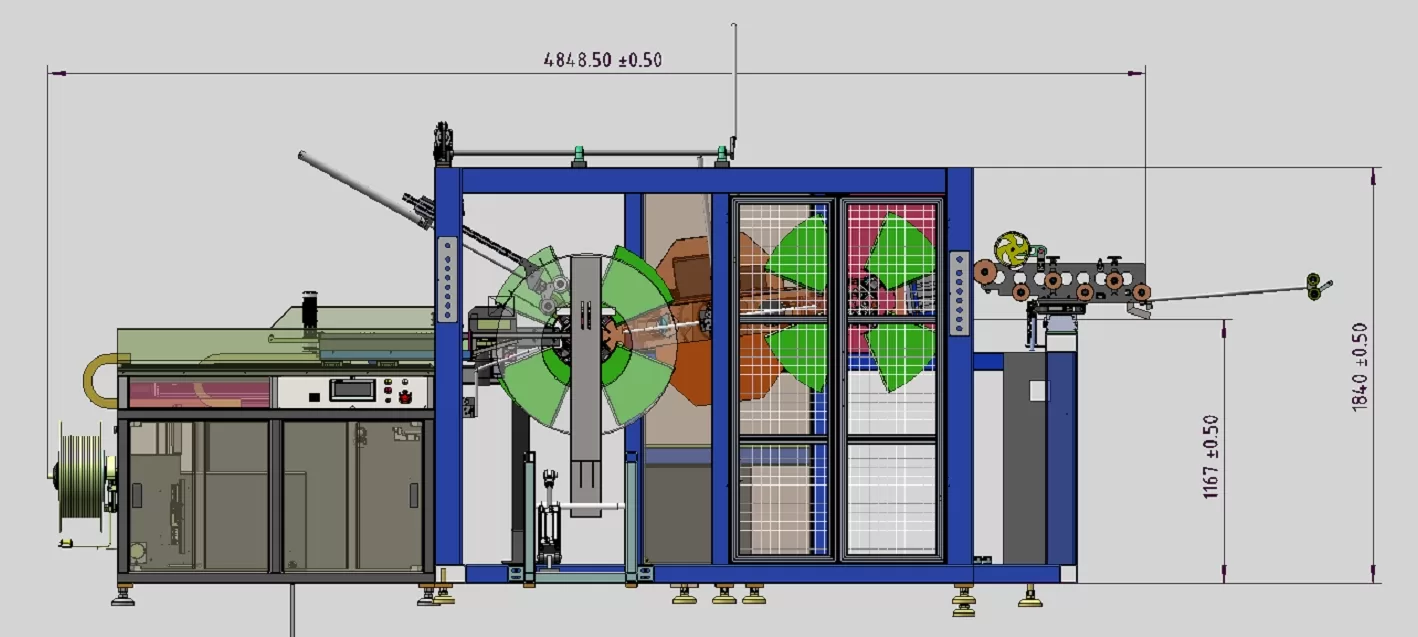

FCL-800 is a automation pipe coiling and strapping equipment that can automatically complete a series of complete steps, from fixing the length, and then winding, cutting, strapping, winding, to the end step of the line. The machine belt and connecting terminal are automatically adjusted by safe weld strapping.The coiling and strapping in highly sucussful rate upto 99%.

Function:

a. PLC and HMI for the operation and parameter setting.

b. Servo system for pipe winding and strapping.

c. Iot monitor and error code for easy trouble shooting.

d. Accuracy pipe length checking and cutting.

e. High sucessful strapping rate.

The coiling speed is upto 80m per minute. The coiling shape of platic pipe coil is union and regular. There are two packing methods to make the product faster and more compact and beautiful after strapping--WRAPPING AND SHRINK WRAP.

|

Machine No.

|

FCL-800A

|

FCL-800B

|

FCL-800C

|

|

coil size

|

OD: Φ500-800mm

Height: 80-200mm

ID: Φ200-300mm

|

OD: Φ500-800mm

Height: 100-300mm

ID: Φ250-500mm

|

OD: Φ500-800mm

Height: 100-300mm

ID: Φ300-600mm

|

|

Tube size

|

OD:5-16mm

|

OD:10-20mm

|

OD:15-30mm

|

|

Air supply

|

6 bar

|

6 bar

|

6 bar

|

|

Meter counter

|

10-50

|

20-100

|

20-200

|

|

Coil feed style mode

|

Automatic

|

Automatic

|

Automatic

|

Note: The machine can be modified per different coil size.

Features:

1. PLC control program.

2. The setting parameters can be used in the control program.

3. The OD of coiling is adjustable.

4. The cutting length of the tube can be adjusted.

5.Two protection devices are used to fix and move the helix.

6.Automatically detect wrong function and alarm when failure occurs.

7.Positioning pipe through sensor.

8.The compression device keeps the tube stable.

9. Automatic binding process control.

10.Different coils can be positioned automatically

11.Adjustable tension of different pipe rings.

12.Connect to the winding machine.

13. Conical roll with lifting function.