Fhopepack Innovation

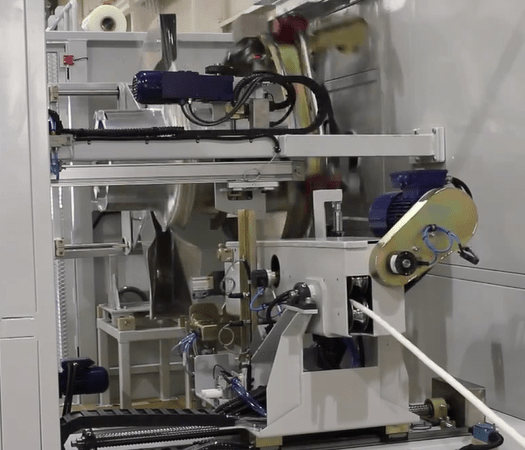

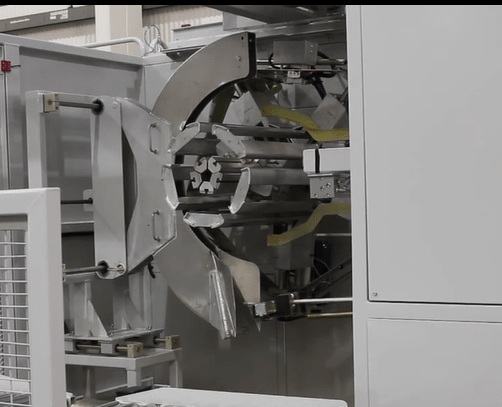

Single head pipe coiler with automatic strapping

Automatic pipe coiling and strapping machine that is specialized for vertical coiling and strapping is a type of handling equipment that is used to shape and secure pipes or hoses into coils. These machines are designed to be highly efficient and can greatly reduce the need for manual labor compared to traditional coiling and strapping processes. One of the key benefits of an automatic pipe coi