Fhopepack Innovation

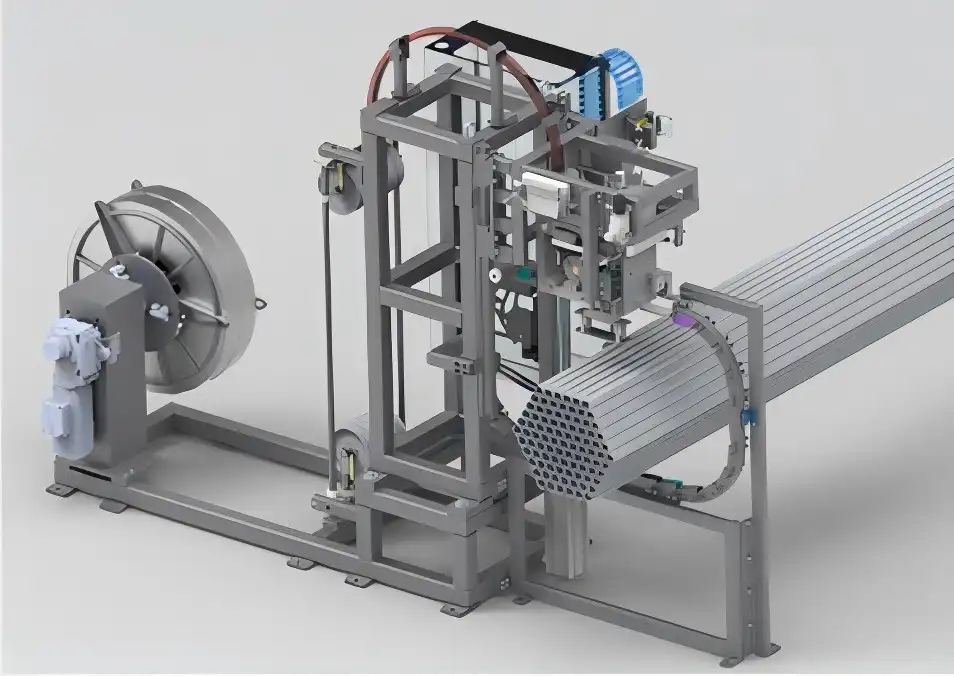

Steel Tube Bundle Strapping Machine | FHOPE

Full- Automatic steel belt strapping machine The process of the strapping by automatic strapping machine with manual operation also. The strapping machine performs all the straps in different strapping position depending on the length of the bundles. The automatic strapping machine is situated at a fixed point and the bundle moves to perform each strapping. Steel Strap : (1)Materials: Cold rolled