China Horizontal Wrapping Machine Factory: A Comprehensive Guide to Finding the Best Supplier

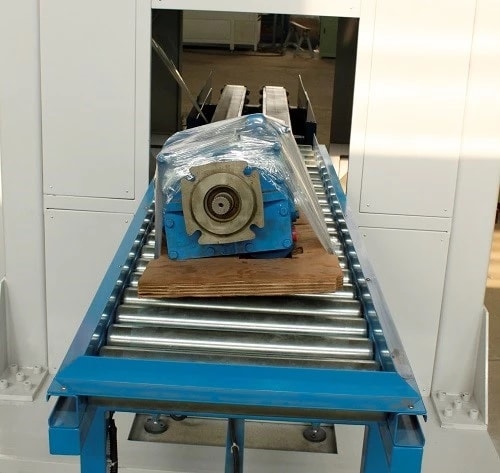

FHOPE is a leading ODM manufacturer of

horizontal wrapping machines, strategically based in Shanghai, East China. With tailored solutions catering to various industries, FHOPE offers an extensive range of machinery that adapts to diverse packaging needs based on unique product shapes, dimensions, and requirements.

Beyond standard items like panels, boards, sheets, steel pipes, and tubes, FHOPE’s product line includes models specifically designed for packaging cement fiberboard and other industrial materials. Moreover, these machines are fully compatible with all types of industrial square balers, making them a versatile choice for complex production lines.

FHOPE also provides continuous stretch film packaging machines that can seamlessly integrate into palletizing and packaging lines, adding automation to reduce packaging material waste and lower labor costs. This automated approach not only enhances operational efficiency but also ensures that products are securely packaged in a durable, visually appealing manner, supporting both functionality and aesthetics. With FHOPE’s advanced technology, companies can achieve high-quality, cost-effective packaging solutions that meet the demands of today’s industrial landscape.

Parameters:

Object size

|

Length:>800mm

Bundle OD:200-600

Weight:20-200kg

|

Infeed conveyor

|

2000mm L×800mmW

|

Outfeed conveyor

|

2000mmL×800mmW

|

Material

|

LLDPE stretch film/ Paper/ Woven

Width: 150-300mm

OD: 100-250mm

ID: 50mm

(Let me know, if you need another size)

|

Air Supply

|

5~8kgf/cm2

|

Conveyor Speed

|

3~12m/min

|

Ring speed

|

App. L5200 x W1800 x H1800mm

|

Power output

|

about 4.5kw

|

Power voltage

|

AC 380v,50Hz,3Phase

|

Control Power voltage

|

ADC24V

|

China Horizontal Wrapping Machine Factory: A Comprehensive Guide to Finding the Best Supplier

In today's fast-paced manufacturing world, efficiency and reliability are crucial. As industries around the globe seek solutions to optimize their packaging processes, one name that consistently rises to the top is China. With its vast network of horizontal wrapping machine factories, China has become a go-to destination for businesses looking for high-quality and cost-effective machinery solutions.

But how do you choose the right supplier from a sea of options? In this article, we’ll dive deep into the key factors that make a Chinese horizontal wrapping machine factory stand out, the benefits of sourcing from China, and what to look for when evaluating potential suppliers.

Introduction to Horizontal Wrapping Machines

Horizontal wrapping machines, often used in industries such as packaging, logistics, and manufacturing, are designed to securely wrap items, ensuring that products are protected during transportation and storage. Whether you’re dealing with furniture, pipes, steel coils, or other large products, horizontal wrapping machines offer robust solutions to improve packaging efficiency and reduce damage during shipment.

China has quickly become a leader in producing these machines, offering innovative designs, competitive pricing, and a wide array of customization options to suit the needs of different industries. Whether you need a machine for a small business or a large-scale manufacturing plant, Chinese suppliers are often the first choice.

Why China is the Leading Manufacturer of Horizontal Wrapping Machines

China’s dominance in the horizontal wrapping machine market is no accident. The country’s manufacturing infrastructure is among the best in the world, supported by technological advancements, skilled labor, and an emphasis on innovation.

-

Cost-Effective Production: China’s low production costs have made it an attractive destination for businesses looking for affordable machinery. The reduced cost doesn’t mean lower quality; instead, it’s a reflection of China’s highly efficient production systems.

-

Wide Range of Options: Whether you’re looking for a semi-automatic or a fully-automated horizontal wrapping machine, Chinese factories provide an incredible range of customization options. This flexibility ensures you can find the right machine that fits your exact needs.

-

Focus on Export Quality: As one of the world’s leading exporters, many Chinese manufacturers adhere to international standards when producing machinery. Factories often ensure that their machines comply with ISO certifications and other global quality standards, ensuring high reliability and durability.

Benefits of Sourcing Horizontal Wrapping Machines from China

When it comes to sourcing horizontal wrapping machines, there are numerous benefits to choosing a factory in China. Beyond just cost savings, there are other advantages that position Chinese manufacturers ahead of the competition:

-

Scalability: Chinese factories are equipped to handle large-scale orders as well as smaller custom orders, making them a versatile option for businesses of all sizes. Their production capabilities allow for quick turnarounds on even the most complex machinery requirements.

-

Advanced Technology Integration: Chinese manufacturers are at the forefront of automation technology, often incorporating the latest innovations such as PLC controls, touch screens, and safety sensors into their machines. This ensures that buyers get a highly efficient and safe machine that can meet the demands of modern packaging environments.

-

Post-Sale Support and Maintenance: Many leading Chinese manufacturers provide comprehensive after-sales support, including maintenance packages, technical assistance, and even training for operators. This helps ensure that your machine runs smoothly long after purchase.

-

Global Shipping and Installation: China’s logistical infrastructure is incredibly advanced, allowing manufacturers to ship products to nearly any location around the world. Many factories also offer installation services, sending a technician to your site to help set up the machine and ensure it operates correctly from day one.

What to Look for in a Chinese Horizontal Wrapping Machine Factory

Finding the right supplier is crucial to ensuring you get a high-quality wrapping machine that fits your business needs. When evaluating potential factories, it’s important to consider a few key factors:

-

Reputation and Experience: A factory with a proven track record of producing horizontal wrapping machines is a good indicator of reliability. Look for manufacturers with positive reviews, a solid history of exports, and client testimonials from businesses in similar industries.

-

Customization Capabilities: Every business has different packaging requirements. A good factory should offer customization options that allow you to tailor the machine to your specific needs, whether it’s modifying the wrapping speed, film tension, or size specifications.

-

Compliance with International Standards: Ensure that the factory follows international manufacturing standards. ISO certification and CE marking are good indicators that the manufacturer adheres to global quality and safety regulations.

Key Technologies Used in Chinese Horizontal Wrapping Machines

When it comes to modern packaging solutions, Chinese manufacturers are leveraging advanced technologies to ensure their wrapping machines offer precision, speed, and safety. Here are some of the cutting-edge technologies you’ll find in Chinese horizontal wrapping machines:

-

Programmable Logic Controllers (PLC): Many Chinese-made wrapping machines come equipped with PLC systems. These systems allow for automation and precise control of the wrapping process, enabling users to adjust speed, film tension, and wrap cycles with ease. PLC integration ensures consistency and accuracy, making it easier to handle different packaging requirements.

-

Touch Screen Interfaces: Modern wrapping machines feature user-friendly touch screen interfaces, simplifying the process of machine operation. These interfaces enable operators to monitor performance, adjust settings in real-time, and troubleshoot errors without needing extensive technical knowledge.

-

Automatic Film Cutter and Clamping System: Chinese horizontal wrapping machines often include automatic film cutting and clamping features, which reduce manual intervention and improve efficiency. This feature is particularly beneficial for high-volume packaging environments where minimizing downtime is essential.

-

Integrated Safety Features: Safety is a top priority for Chinese manufacturers, and many machines come with advanced safety features like emergency stop buttons, safety sensors, and protective barriers to reduce the risk of accidents. These technologies help ensure that machines meet international safety standards and provide operators with a secure working environment.

Evaluating the Cost-Effectiveness of Chinese Horizontal Wrapping Machines

When considering purchasing a horizontal wrapping machine from China, cost-effectiveness is often a primary concern for businesses. While Chinese manufacturers are known for their competitive pricing, it’s important to evaluate the total cost of ownership, not just the initial purchase price.

-

Affordable Initial Investment: Chinese factories benefit from economies of scale and low labor costs, allowing them to offer competitive pricing on machinery without sacrificing quality. This makes them an ideal choice for businesses that want to minimize upfront costs.

-

Lower Operating Costs: Many Chinese-made wrapping machines are designed with energy-efficient motors and minimal maintenance requirements, reducing long-term operating costs. Additionally, features like automatic film cutting and tension control help to optimize material usage, ensuring you get the most out of your wrapping film.

-

Durability and Long Lifespan: Despite their affordability, Chinese horizontal wrapping machines are built to last. Using high-quality materials such as stainless steel and durable components, these machines can withstand the rigors of industrial environments, ensuring you get a long lifespan from your investment.

-

Customization to Fit Your Budget: Many Chinese manufacturers offer customization options that allow you to choose features that fit your budget. Whether you need a basic model or a more technologically advanced machine, there are options for every price point.

How to Choose a Reliable Horizontal Wrapping Machine Factory in China

Choosing the right supplier can be challenging, especially when dealing with overseas manufacturers. To ensure you partner with a reliable factory, here are some tips to guide your decision-making process:

-

Factory Audits and Visits: Whenever possible, consider conducting a factory audit or visiting the facility in person. This will give you a chance to see the production process, inspect the quality control measures, and meet the team behind the operation. If an in-person visit isn’t feasible, many factories offer virtual tours or provide comprehensive documentation about their operations.

-

Check References and Reviews: Reliable manufacturers often have a history of satisfied clients. Ask for references or check online reviews to gauge the factory’s reputation. Customer testimonials can provide insights into the factory’s responsiveness, quality of products, and after-sales support.

-

Request Product Samples: Before placing a large order, ask the factory to provide product samples. This will allow you to evaluate the machine's quality, ensure it meets your specifications, and confirm that it aligns with international standards.

-

Communication and Support: Ensure that the factory offers clear and open communication throughout the entire purchasing process. A factory that provides prompt responses to inquiries, technical support, and transparent timelines is more likely to be a reliable long-term partner.

Importance of Post-Sale Services and Support

Purchasing a horizontal wrapping machine is just the first step. It’s essential to consider the after-sales support offered by the factory, as this can greatly impact the longevity and performance of your machine. Key post-sale services to look for include:

-

Installation and Training: Many Chinese factories offer on-site installation services, ensuring that your machine is set up correctly. Additionally, they often provide training sessions for your team to ensure they can operate the machine efficiently.

-

Maintenance and Spare Parts: Choose a manufacturer that offers ongoing maintenance services and guarantees the availability of spare parts. Regular maintenance will ensure that your machine continues to perform at its best and helps to prevent unexpected downtime.

-

Warranty and Technical Support: A factory that offers a comprehensive warranty and round-the-clock technical support is a sign of a reputable supplier. This can provide peace of mind, knowing that any issues will be handled quickly and professionally.

Understanding Shipping and Logistics for Horizontal Wrapping Machines from China

Importing large machinery like a horizontal wrapping machine requires careful consideration of shipping and logistics. Here’s what you need to know when ordering from China:

-

Global Shipping Network: China’s position as a global manufacturing hub means that its factories are well-versed in international shipping procedures. Many factories have established global logistics networks, ensuring timely deliveries to almost any part of the world.

-

Packaging and Handling: Chinese manufacturers typically package machines in durable wooden crates to prevent damage during transit. However, it’s always wise to confirm that your machine will be adequately protected, especially for long-distance shipping.

-

Customs and Import Duties: Before placing an order, it’s important to understand the customs regulations and import duties in your country. Most Chinese manufacturers can assist with the paperwork needed to streamline the import process.

Conclusion

China’s horizontal wrapping machine factories provide a reliable and cost-effective solution for businesses around the world. By leveraging cutting-edge technology, competitive pricing, and a focus on customization and quality, these factories have established themselves as leaders in the industry.

When selecting a supplier, consider factors like reputation, customization options, compliance with international standards, and after-sales support. By choosing a trusted factory, you can ensure that your business benefits from a high-quality machine that will improve efficiency, reduce costs, and enhance your overall packaging operations.

In conclusion, investing in a Chinese horizontal wrapping machine is a smart decision for companies looking to boost their packaging capabilities without breaking the bank. By doing thorough research and selecting a reliable supplier, you’ll be well-positioned to enjoy the many benefits these machines offer for years to come.