Orbital Stretch Wrapper Price Guide: What You Need to Know Before You Buy

If you’re in the manufacturing or logistics sector, chances are you’ve heard of orbital stretch wrappers. These machines are a mainstay for efficiently wrapping long or oddly shaped products—from metal profiles and tubes to wood planks and furniture parts. As demand grows for streamlined packaging solutions, more businesses are turning to orbital stretch wrappers to speed up operations and reduce labor costs. But how much does an orbital stretch wrapper actually cost, and why do prices vary so much? In this guide, we’ll break down typical price ranges, influencing factors, and cost-saving tips, so you can decide which model best fits your needs and budget.

What Is an Orbital Stretch Wrapper?

An orbital stretch wrapper is a packaging machine designed to wrap elongated products with stretch film by rotating the roll of film around a horizontal or vertical ring. Unlike a traditional turntable-style stretch wrapper—where the pallet itself rotates—the orbital wrapper’s ring moves around the stationary product. This design allows for a more efficient wrap on items that are long, cylindrical, or highly irregular in shape.

Orbital wrappers are popular in industries like metal fabrication (e.g., steel tubing, extrusions, beams), furniture manufacturing, home construction materials, and more. Because the product doesn’t rotate, orbital wrapping reduces potential damage to delicate or heavy items.

Typical Orbital Stretch Wrapper Price Ranges

Just like any capital equipment, orbital stretch wrappers span a wide price range, from basic entry-level units to high-end, fully automated solutions. Below is a broad overview of what you can expect:

-

Basic Semi-Automatic Models:

-

Price Range: $1,000 to $15,000

-

Who It’s For: Smaller operations that want to improve packaging efficiency but don’t require high throughput. Often good for entry-level usage or intermittent wrapping needs.

-

Features: Manual product positioning, semi-automatic film feed, and basic control panels.

-

Mid-Tier Automated Models:

-

Price Range: $5,000 to $20,000

-

Who It’s For: Medium-sized manufacturers with consistent daily volume. These models often come with automated film clamping, cutting, and more advanced controls.

-

Features: Programmable settings, partial automation, user-friendly HMI (human-machine interface), higher throughput than basic models.

-

High-End Fully Automatic/High-Capacity Systems:

-

Price Range: $10,000 and up (some can exceed $80,000)

-

Who It’s For: Large-scale production lines needing minimal human intervention. Ideal for 24/7 operations.

-

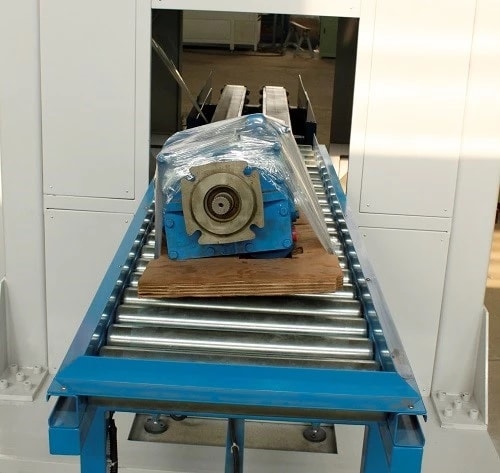

Features: Conveyor integration, robotic arms or automated infeed/outfeed, sophisticated control systems, and advanced safety guards. Typically faster throughput and more customization options.

Remember, these are ballpark figures. Individual prices can vary based on supplier margins, regional tariffs, brand reputation, and customization packages.

Factors Influencing Orbital Stretch Wrapper Costs

-

Load Capacity and Ring Size

The diameter of the wrapper’s ring or “band” dictates which product dimensions can fit. Larger rings are more expensive to manufacture and require more robust motors and controls.

-

Automation Level

Higher automation—such as automated film clamping, cutting, and conveyor integration—adds to the machine’s sticker price. However, automation can reduce labor costs in the long run.

-

Film Prestretch and Tension Control

A quality prestretch system can stretch film by up to 200–300% before it is applied, dramatically reducing film usage. Machines with advanced tension control often cost more but deliver better ROI through material savings.

-

Brand and Build Quality

Reputable brands that provide robust support, longer warranties, and better components usually charge a premium. However, you often get improved durability, fewer breakdowns, and quicker replacement parts—key considerations in a busy production environment.

-

Customization

If your facility needs special modifications—like multi-point sensor arrays, custom safety enclosures, or specialized conveyors—expect higher upfront costs.

-

Ancillary Equipment

Add-ons like outfeed conveyors, label applicators, or corner board applicators can quickly add thousands of dollars to your total project cost.

Comparing Semi-Automatic vs. Fully Automatic

|

Feature

|

Semi-Automatic

|

Fully Automatic

|

|

Initial Cost

|

Lower ($10k–$25k)

|

Higher ($50k+)

|

|

Operator Involvement

|

Operator needs to start/stop wrap cycles, attach and cut film manually

|

Minimal; the system automates clamping, cutting, and wrapping

|

|

Throughput

|

Moderate

|

High

|

|

Maintenance Complexity

|

Generally simpler

|

More complex, requires specialized technicians

|

|

Best Suited For

|

Small to medium loads, intermittent usage

|

Large-scale, constant production environments

|

For many businesses on a tight budget, semi-automatic wrappers are a good first step. They strike a balance between efficiency and cost. Meanwhile, high-volume operations often find fully automatic systems more economical in the long run, thanks to reduced labor and faster throughput.

New vs. Used Machines

If you’re particularly budget-conscious or just starting out, used or reconditioned orbital stretch wrappers can be a viable alternative to buying new:

-

Pros: Lower upfront cost; availability of reputable used-equipment dealers; potentially faster delivery.

-

Cons: Shorter warranty periods (if any); uncertain machine history; might lack modern automation or safety features.

When shopping for used equipment, always request maintenance records and thoroughly inspect the machine for wear on motors, bearings, and film carriage assemblies. A slight discount upfront can lead to higher service costs if the system isn’t in top shape.

Total Cost of Ownership (TCO)

Price tags alone don’t tell the whole story. Over the lifespan of the machine—which can be 10+ years with proper maintenance—operational expenses, maintenance, and downtime can far outweigh the original purchase cost. Here’s a quick breakdown of common TCO considerations:

-

Maintenance & Service

-

Preventive maintenance intervals

-

Costs for replacement parts (gearboxes, belts, rollers)

-

Availability of in-house service technicians vs. external service calls

-

Energy Consumption

-

Motor efficiency

-

Operating hours per day

-

Potential rebates for energy-efficient models

-

Film Consumption

-

Prestretch capabilities

-

Tension control to minimize film waste

-

Downtime Costs

-

Production bottlenecks if the wrapper is offline

-

Lost labor and potential delayed shipments

-

Warranty & Support

-

Standard coverage vs. extended plans

-

Supplier’s service network reach

-

Availability of local technicians

Before locking in on a price, make sure you’re comparing overall value. A higher-priced machine with superior reliability and more advanced film-saving features may yield a lower total cost over time than a cheaper entry-level alternative.

Why Orbital Stretch Wrapper Prices Vary Among Suppliers

You might come across multiple suppliers offering essentially the “same” machine at different prices. Why is that?

-

Supplier Margins & Brand Positioning: Some brands simply price at a premium to position themselves as top-tier. Others compete on cost to attract budget-conscious buyers.

-

Geographic Location: Import duties, shipping, and local taxes can affect final pricing.

-

Certification & Quality Standards: If a machine meets advanced safety or industry-specific certifications (e.g., CE marking in Europe or UL listing in the U.S.), it can command a higher price.

-

Customer Support & Service Packages: Some suppliers bundle training and extended warranties, which can raise the sticker price but may reduce headaches later.

Is a Used Orbital Wrapper a Good Investment?

For budget-focused operations or start-ups, a used orbital stretch wrapper can provide a shortcut to more efficient packaging without the high upfront investment. However, the key is in your due diligence:

-

Verify Machine History: Look for documentation of regular maintenance.

-

Check for Upgradable Features: If the control system is too old, it may not be compatible with future expansions or automation upgrades.

-

Inspect Wear Components: The film carriage assembly, ring bearings, and drive motors are all critical wear points.

If you find a well-maintained used machine from a reputable reseller, it can be an effective way to stretch your packaging budget. Just be prepared that older models might lack the latest automation or advanced safety features.

Financing Options to Consider

Investing in capital equipment doesn’t have to drain your cash flow. Many manufacturers and suppliers provide financing or leasing options:

-

Equipment Leasing: Make fixed monthly payments over a set term, often with an option to purchase the machine at lease end.

-

Bank Financing or Loan: Traditional lending can be arranged if you have established credit.

-

Supplier Financing: Some OEMs offer in-house financing or payment plans to encourage buyers to choose their brand.

-

Bulk Purchase Discounts: If you’re equipping multiple facilities or placing a large order, ask about volume discounts.

Evaluate your current financial situation and projected returns. A slightly higher interest rate might be acceptable if faster automation drastically boosts productivity and revenue.

Key Takeaways & Next Steps

-

Understand Price Ranges: Expect to spend anywhere from $10,000 for a basic semi-automatic orbital wrapper to well over $50,000 for a fully automated, high-capacity solution.

-

Pinpoint Your Needs: Evaluate throughput, load sizes, and desired automation level before settling on a price bracket.

-

Remember TCO: Maintenance costs, film usage, and downtime matter just as much as the upfront purchase.

-

Compare Multiple Quotes: Don’t just compare sticker prices—look at warranties, service support, and brand reputation.

-

Consider Pre-Owned: A well-maintained used wrapper can be a solid investment, provided you verify its condition and service history.

With these key insights, you’re better positioned to shop around. Orbital stretch wrappers can dramatically boost packaging efficiency and reduce labor costs—if you choose the right model.

Frequently Asked Questions (FAQs)

-

How much does an orbital stretch wrapper cost?

Most entry-level models start around $10,000, while fully automated, large-capacity wrappers can exceed $50,000. Price depends on size, automation, and brand.

-

Which type of orbital wrapper offers the best ROI?

High-throughput automated wrappers often yield the best long-term ROI if your production volume justifies the higher initial investment.

-

Can I find budget-friendly alternatives?

Yes. Refurbished or used machines can be significantly cheaper upfront. Just ensure you purchase from a reputable reseller and check the machine’s maintenance history.

-

Why do prices vary across suppliers?

Costs are influenced by brand reputation, quality standards, regional import fees, and the level of after-sales support included.

-

Is financing available?

Many suppliers offer leasing or financing plans to ease the burden of large cash outlays. Your best approach is to compare rates and terms across multiple providers.

Ready to Take the Next Step?

If you’re looking to increase your packaging efficiency, reduce labor costs, and protect your products more effectively, an orbital stretch wrapper might be the perfect solution. Contact us today for a custom quote or try our online price calculator to see how various specifications affect your total investment. By combining the right machine with solid after-sales support, you’ll be well on your way to streamlined operations and a healthier bottom line.

In summary, the price of orbital stretch wrappers depends on factors such as machine size, automation level, brand reputation, and added features like prestretch capabilities or advanced safety systems. By understanding the full breadth of available options—semi-automatic versus fully automatic, new versus used—and how total cost of ownership can overshadow the initial purchase price, you’ll be in an excellent position to make a confident buying decision.