YouTube Orbital Wrapping Machine

In today's fast-paced packaging world, the YouTube Orbital Wrapping Machine is revolutionizing how products are secured and transported. Whether you're a large-scale manufacturer or a small business owner, the demand for efficient and reliable packaging solutions is more pressing than ever. But what exactly makes the YouTube Orbital Wrapping Machine stand out? Its unique capabilities and customizable features have caught the attention of companies striving for maximum productivity and minimum downtime. If you're considering investing in one, it's crucial to understand its benefits and how it compares to other options available in the market. The ultimate goal? To ensure your packaging line operates at peak efficiency.

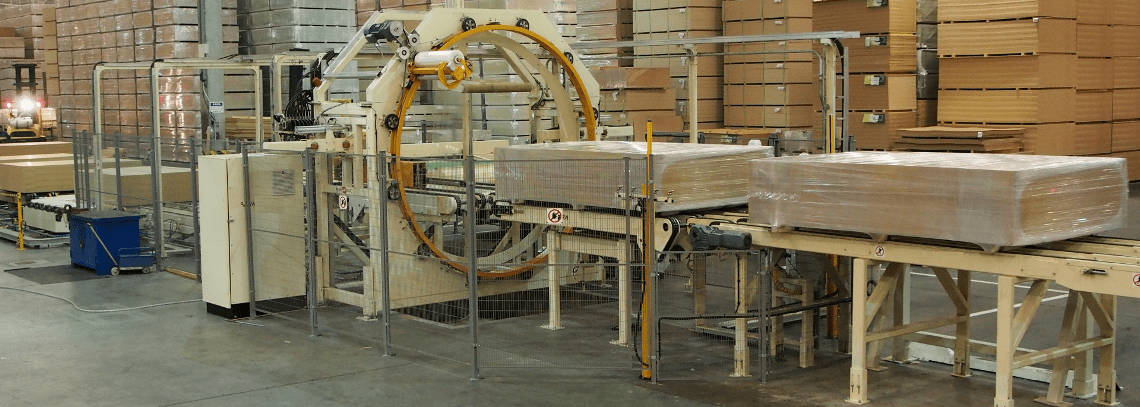

The concept of orbital wrapping has transformed traditional packaging processes, offering an advanced alternative to standard stretch wrapping systems. This machine uses a rotating arm that wraps film around products, creating a secure and consistent packaging layer. The beauty of orbital wrapping lies in its ability to adjust to various product shapes and sizes, ensuring a perfect wrap every time. But what makes the YouTube Orbital Wrapping Machine particularly noteworthy? Its integration with cutting-edge technology and customizable features can increase operational efficiency, reduce material waste, and improve product protection during transit.

Understanding the true value of the YouTube Orbital Wrapping Machine goes beyond its surface-level benefits. As we delve deeper into the specific advantages and considerations, it becomes clear that businesses that adopt this machine are not just improving their packaging processes; they’re enhancing their overall operational workflows. The next question is: how do you assess whether this machine aligns with your specific needs and production goals?

1. What Are the Key Benefits of a YouTube Orbital Wrapping Machine?

1.1 Increased Efficiency and Speed

In today’s highly competitive manufacturing environment, efficiency is everything. The YouTube Orbital Wrapping Machine excels in speed, allowing businesses to wrap products faster than traditional methods. Unlike manual wrapping or older machinery, which may struggle with larger or irregularly shaped products, this machine ensures quick, consistent results every time. By increasing the speed of packaging, it helps businesses meet demanding production schedules without compromising on quality or safety.

With its ability to wrap multiple items simultaneously or in quick succession, this machine significantly cuts down on the time spent on each product. It’s especially beneficial in industries where high throughput is essential, such as food production, electronics, or logistics. The time saved translates into higher overall productivity, enabling businesses to scale their operations and meet customer demands with ease.

1.2 Flexibility for Different Products and Applications

The adaptability of the YouTube Orbital Wrapping Machine is one of its most significant advantages. Thanks to its customizable settings, this machine can handle a wide range of product types, from irregularly shaped items to oversized loads. Whether you're wrapping pipes, machinery parts, or pallets of goods, the machine can adjust to different dimensions and ensure a secure, tight wrap that protects the contents.

Additionally, its orbital wrapping process provides excellent film coverage, even around odd shapes or delicate items, which minimizes the risk of damage during shipping. For industries that deal with fragile or high-value products, this added protection is invaluable. The film can also be adjusted for varying tension and overlap, providing the right amount of security without wasting materials.

1.3 Reducing Material Waste and Lowering Costs

One of the major operational concerns for packaging processes is material waste, which contributes directly to increased costs. The YouTube Orbital Wrapping Machine excels in this area by using precisely the right amount of film to secure each product. Its advanced settings allow operators to fine-tune the film tension, reducing the overuse of materials that often happens in manual or less advanced machines.

Additionally, because the machine applies the film evenly and tightly, it ensures that products are securely wrapped without the need for excess wrapping. Over time, these small reductions in material usage can result in significant cost savings for a company. Businesses can also reduce their environmental footprint by using less plastic film, aligning with sustainability goals.

2. How Does the YouTube Orbital Wrapping Machine Compare to Traditional Wrapping Systems?

2.1 Speed and Productivity

Traditional wrapping systems, such as manual hand wrapping or even older automated machines, often struggle to match the efficiency levels of the YouTube Orbital Wrapping Machine. These systems typically require more time and human labor to wrap each product, especially when dealing with large or unusually shaped items. For instance, manual wrapping demands precision and time, which can slow down the overall production process.

In comparison, the YouTube Orbital Wrapping Machine automates this process, increasing throughput without sacrificing wrap quality. The consistency in speed ensures that your packaging line can maintain a steady pace, accommodating larger production volumes without additional labor costs or delays.

2.2 Consistency and Reliability

Another area where the YouTube Orbital Wrapping Machine outshines traditional systems is in consistency. While manual wrapping is subject to human error—resulting in inconsistent wraps or damage to the product—this machine ensures a perfect wrap every time. The orbital wrapping method guarantees even distribution of film, reducing the chances of loose or uneven packaging.

Traditional systems, on the other hand, may struggle to wrap products with complex shapes, often leading to the need for rework or adjustment. This can result in longer packing times, reduced output, and more frequent machine downtime. The YouTube Orbital Wrapping Machine, by contrast, provides a reliable solution that minimizes downtime and maximizes efficiency.

2.3 Lower Maintenance and Downtime

The YouTube Orbital Wrapping Machine is designed with durability in mind, requiring less maintenance than many traditional wrapping systems. Older machines, especially those with more mechanical components, often need frequent repairs or adjustments to maintain performance. These machines can experience breakdowns during peak production times, causing delays and costing businesses valuable time.

Thanks to its automated and self-regulating systems, the YouTube Orbital Wrapping Machine minimizes the risk of unexpected downtime. This reliability ensures that packaging lines remain operational, contributing to higher productivity and reducing the likelihood of costly interruptions in the production cycle.

3. What Factors Should You Consider When Choosing a YouTube Orbital Wrapping Machine for Your Business?

3.1 Compatibility with Your Existing Equipment

Before purchasing a YouTube Orbital Wrapping Machine, it's essential to assess how well it integrates with your current packaging line. Many businesses already use automated machinery or conveyors to transport goods, and the last thing you want is to introduce a machine that disrupts your existing workflow. Compatibility with your setup ensures a smoother transition and reduces the need for costly upgrades or modifications.

This machine is known for its versatility, but you must verify that its specifications align with your operational requirements. Check whether the machine can handle the weight and size of the products you typically package, as well as the film materials you use. A seamless fit with your existing systems can make a big difference in terms of efficiency and overall productivity.

3.2 Maintenance and Support Options

Another critical factor to consider is the maintenance and support options available for the YouTube Orbital Wrapping Machine. As with any advanced machinery, regular maintenance is key to keeping it running at optimal levels. Look for machines that come with comprehensive support packages, including regular servicing, troubleshooting, and easy access to spare parts.

The reliability of after-sales support is an area that should not be overlooked. An unreliable support network can lead to unnecessary downtime and potentially expensive repairs. Ensure that your supplier offers adequate training for your operators and technicians to handle minor issues in-house. Additionally, check if the manufacturer provides warranty options and maintenance contracts for added peace of mind.

3.3 Customization and Features

Every business has its unique requirements when it comes to packaging, which is why the customization options of the YouTube Orbital Wrapping Machine are crucial. The best machines come with adjustable settings that allow you to tailor the wrapping process to the specific dimensions and packaging materials of your products.

For instance, you may need specific settings for tension control, film overlap, and speed adjustments depending on the type of items being wrapped. Machines that offer these kinds of customizable options are more flexible and can be adapted to changing needs as your business evolves. Moreover, the addition of features like automatic film cutting and integrated sensors for alignment can improve both the speed and precision of the wrapping process, making your packaging line even more efficient.

4. How Can You Integrate a YouTube Orbital Wrapping Machine Into Your Existing Packaging Line?

4.1 Assessing Workflow and Integration Needs

When you're looking to integrate the YouTube Orbital Wrapping Machine into your current packaging line, the first step is to analyze your existing workflow. Understanding how goods are transported, sorted, and wrapped will help you determine where the machine should be placed and how it will interact with other equipment. This will also help in figuring out any potential bottlenecks in the process.

If your packaging line already includes automated conveyors or robotic arms, integration will be smoother. The orbital wrapping machine can be placed at the end of the line, where it will automatically receive products and wrap them without manual intervention. However, if your system is less automated, you may need to invest in additional equipment to facilitate a smooth connection between processes.

4.2 Training and Familiarizing Your Team

Once the machine is in place, training is essential to ensure that your team is equipped to handle it efficiently. Unlike manual wrapping, operating the YouTube Orbital Wrapping Machine requires specific knowledge of its controls and settings. This includes understanding how to adjust film tension, wrapping speed, and the wrap layers for different product types.

Provide your team with proper training from the machine manufacturer or supplier, ensuring that both operators and maintenance staff are well-versed in troubleshooting, replacing components, and conducting regular maintenance. Properly trained personnel will ensure that the machine operates smoothly, minimizing downtime and increasing operational efficiency.

4.3 Monitoring and Continuous Improvement

After the machine is integrated and the initial training is complete, it's essential to monitor its performance over time. Collect data on key metrics such as wrapping speed, material usage, and product protection to assess the machine's effectiveness in your packaging line. This will allow you to make adjustments if necessary and maximize the machine's potential.

Additionally, regularly revisiting your machine’s settings and evaluating its impact on your workflow can help identify areas for improvement. This continuous improvement mindset can lead to more streamlined processes and long-term gains in efficiency, as well as a reduction in material waste and labor costs.