Board Orbital Wrapping Machine

Packaging large or irregularly shaped items can be a logistical nightmare. Traditional methods often lead to inefficiencies, material wastage, or even damage during transit. Enter the board orbital wrapping machine, a groundbreaking solution that promises to revolutionize how industries handle their packaging needs. This machine combines advanced technology with precision to ensure secure, efficient, and eco-friendly wrapping, making it a must-have for modern operations.

When it comes to improving packaging efficiency, investing in the right equipment can significantly impact your bottom line. But how exactly does a board orbital wrapping machine transform operations? Let’s delve into its mechanics, advantages, and why it's becoming the industry standard.

With an increasing emphasis on sustainable practices and operational efficiency, understanding the capabilities of these machines isn’t just beneficial—it’s essential for businesses aiming to stay competitive.

1. What Are the Core Benefits of a Board Orbital Wrapping Machine?

1.1 Why is this machine a game-changer for businesses?

The board orbital wrapping machine redefines how products are secured during packaging by providing a level of precision and uniformity that traditional methods can’t match. Its primary advantage lies in its ability to tightly wrap items, regardless of their dimensions, ensuring consistent protection during handling and transportation.

Its automated design drastically reduces manual intervention, cutting down on labor costs while minimizing human errors. This efficiency translates to increased throughput, enabling businesses to meet tight deadlines without compromising on quality.

1.2 How does it align with sustainability goals?

The demand for sustainable packaging solutions is at an all-time high. Board orbital wrapping machines help businesses achieve these goals by optimizing material usage. Unlike manual wrapping methods, these machines apply just the right amount of stretch film to secure items, reducing waste.

Additionally, the high precision of these machines ensures that fewer resources are required to redo damaged packaging, which further minimizes environmental impact. Their design also allows for the use of biodegradable or recyclable films, making them a green choice for eco-conscious companies.

1.3 Dive deeper: How do they ensure cost-effectiveness?

Cost-effectiveness in packaging comes from two main areas: material savings and operational efficiency. By optimizing the amount of film used and ensuring that every wrap is perfect, businesses see significant savings in their packaging costs.

Moreover, the speed and consistency offered by these machines enable higher productivity levels, ensuring that more packages can be wrapped in less time. This not only meets customer demands faster but also reduces energy consumption per package, adding to the overall cost savings.

2. How Does It Enhance Operational Efficiency in Packaging Lines?

2.1 What makes it indispensable for high-volume operations?

In a high-volume packaging environment, time is money. Board orbital wrapping machines are designed with speed and efficiency in mind, capable of wrapping items at rates far exceeding manual methods. Their automated systems ensure seamless integration into existing production lines, eliminating bottlenecks and maintaining consistent output.

The uniformity of the wraps ensures that products are securely protected, reducing the likelihood of damage during transit—a critical factor for maintaining customer satisfaction.

2.2 Why do automation and precision matter so much?

Automation eliminates variability caused by manual processes, ensuring every package is wrapped to the same high standard. This precision is especially crucial for products with irregular shapes or fragile components, where consistent tension and coverage are vital.

By relying on advanced sensors and controls, these machines adjust their operation to accommodate different product dimensions, further enhancing their versatility and reliability.

2.3 Dive deeper: How do these machines improve worker safety?

Worker safety is a top priority in any manufacturing environment. Traditional manual wrapping methods often require repetitive motions, leading to fatigue or even injuries over time. Board orbital wrapping machines mitigate these risks by automating the process, reducing the need for direct human involvement.

Additionally, these machines are equipped with advanced safety features such as emergency stop functions, protective barriers, and user-friendly controls, ensuring that operators remain safe throughout their operation. This shift not only protects employees but also reduces downtime caused by workplace injuries, further enhancing productivity.

3. Why Is It the Preferred Choice for Large or Irregular Items?

3.1 What challenges do irregularly shaped items pose, and how does this machine address them?

Packaging irregularly shaped items has long been a struggle for businesses. Manual wrapping methods often result in inconsistent tension, uneven coverage, and even product damage. The board orbital wrapping machine addresses these challenges with its innovative design and precise mechanisms.

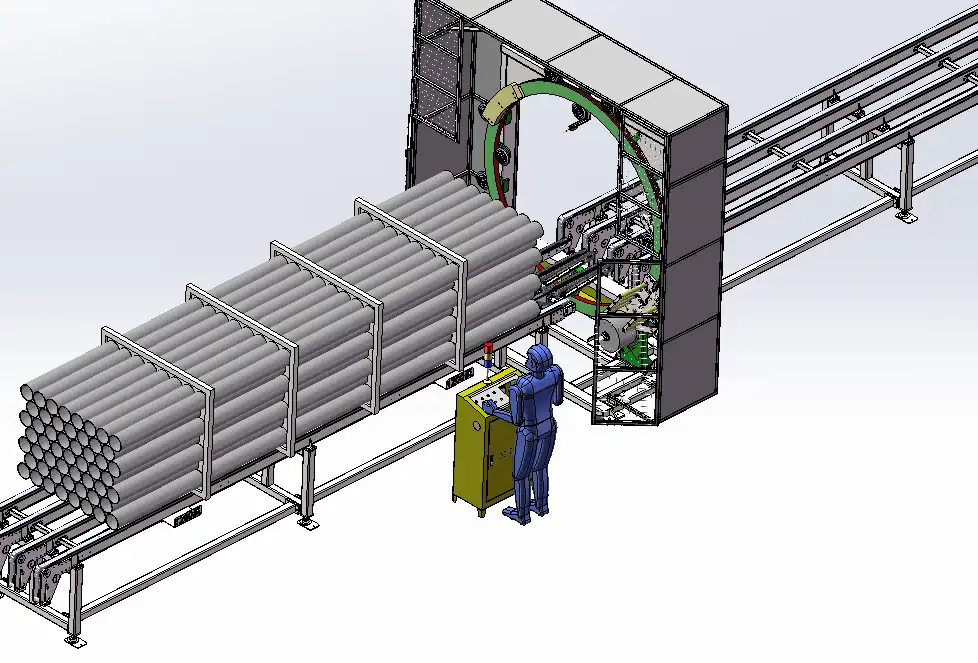

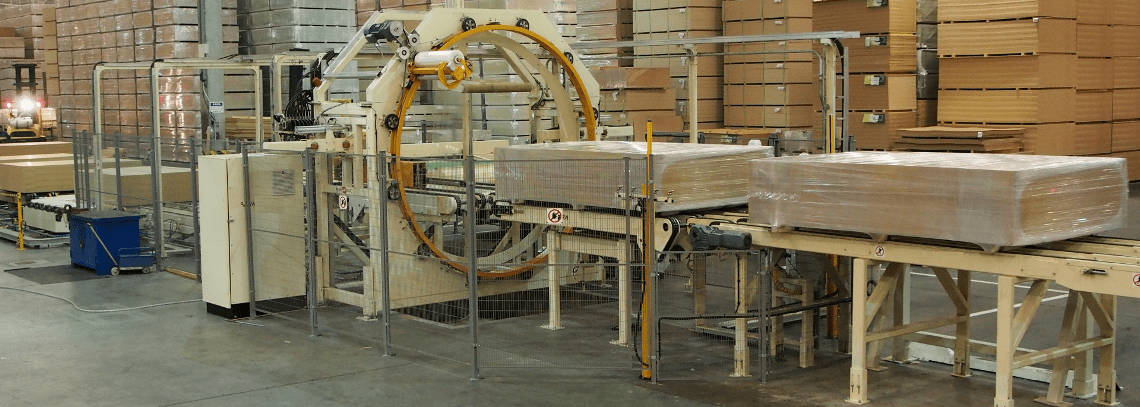

Its rotating ring technology allows for 360-degree wrapping, ensuring that every corner and curve of the item is covered securely. This adaptability makes it the preferred choice for industries handling oversized boards, furniture, or oddly shaped machinery.

3.2 What industries benefit most from this technology?

Industries dealing with heavy-duty or non-standard products, such as construction materials, manufacturing equipment, and furniture, benefit immensely from these machines. The automation and efficiency offered by orbital wrappers allow companies to streamline their operations while maintaining high packaging standards.

For example, in the construction sector, oversized boards or panels often require careful handling. Orbital wrapping machines ensure that these items are securely bundled, reducing the risk of damage during transportation. Similarly, manufacturers of industrial components rely on these machines for consistent and protective packaging.

3.3 Dive deeper: How do they reduce transportation risks?

Transportation of large or irregular items comes with a unique set of risks, including shifting loads, exposure to environmental elements, and potential damage from mishandling. The board orbital wrapping machine mitigates these risks by creating a tight and uniform wrap around the item.

This secure packaging not only prevents movement during transit but also provides an additional layer of protection against moisture, dust, and physical impacts. By reducing the likelihood of transit-related damages, businesses can save significantly on replacement costs and maintain strong customer satisfaction levels.

4. What Features Should You Look for in a Reliable Machine?

4.1 Why does machine build quality matter?

The build quality of a board orbital wrapping machine directly impacts its longevity and performance. Machines constructed with durable materials and precision engineering are better equipped to handle the demands of high-volume operations.

Investing in a robust machine ensures consistent performance over time, reducing the need for frequent maintenance or replacement parts. This reliability is particularly crucial for businesses with tight production schedules, where downtime can lead to significant losses.

4.2 What role do customization and scalability play?

Every business has unique packaging requirements, and a one-size-fits-all approach rarely works. High-quality orbital wrapping machines offer customizable features such as adjustable ring sizes, tension controls, and compatibility with various wrapping materials.

Scalability is another critical factor. As your business grows, the machine should be able to adapt to increased production volumes or different product types, ensuring it remains a valuable asset for years to come.

4.3 Dive deeper: Why is after-sales support essential?

No matter how advanced a machine is, it’s only as good as the support behind it. Reliable after-sales service ensures that businesses can quickly resolve any technical issues, minimizing downtime.

Look for manufacturers or suppliers that provide comprehensive training, regular maintenance, and readily available replacement parts. These services not only extend the life of the machine but also give businesses the confidence to operate without disruptions.

Conclusion

The board orbital wrapping machine represents a pivotal advancement in packaging technology, addressing inefficiencies and challenges that businesses have faced for decades. Its ability to handle irregularly shaped items, enhance operational efficiency, and align with sustainability goals makes it an indispensable tool for modern industries.

Whether your focus is on reducing costs, improving productivity, or meeting eco-friendly standards, investing in the right machine is a strategic move that can propel your business forward.