Board Orbital Wrapping Machine

Packaging solutions have seen remarkable advancements in recent years, especially in the world of industrial-grade equipment. Among these, the board orbital wrapping machine has become a cornerstone for businesses looking to ensure secure and efficient product packaging. If you’ve ever wondered how your large boards, panels, or flat products are securely wrapped for transport, this marvel of engineering is the answer.

This article dives into the intricacies of board orbital wrapping machines, their applications, and why they’re indispensable in modern industries. Let's unravel the story behind this technological innovation!

1. What makes board orbital wrapping machines essential for industries?

1.1 How do they work?

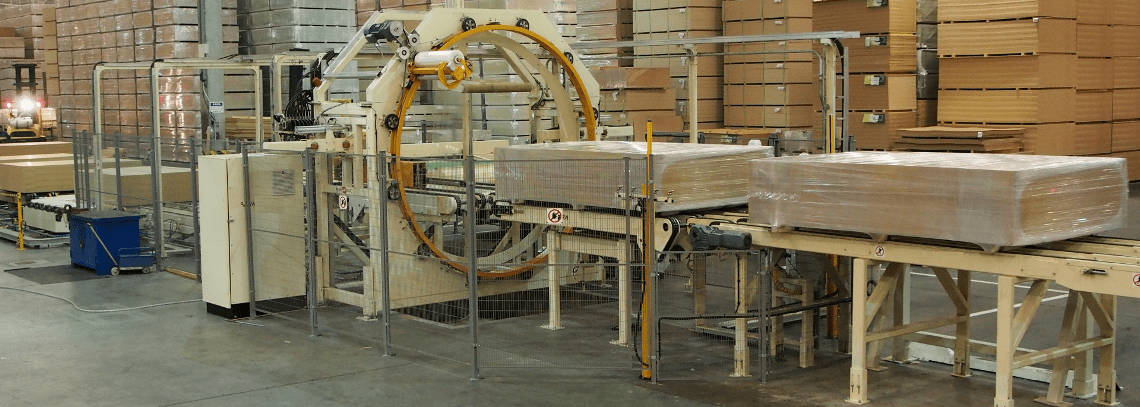

Board orbital wrapping machines function by encasing flat or elongated products, such as wooden boards, panels, or large sheets, in layers of protective film. The "orbital" in their name refers to the machine's circular motion around the object being wrapped, ensuring 360-degree coverage. These machines operate on a turntable or conveyor system, automating the wrapping process with precision.

For instance, imagine a large glass panel ready for shipment. It’s fragile and prone to scratches during transit. A board orbital wrapping machine ensures it is enveloped in protective layers, safeguarding it against damage while minimizing material waste.

By integrating sensors and adjustable settings, modern machines cater to products of varying dimensions, ensuring uniform wrapping every time.

1.2 Industries benefiting the most

The demand for board orbital wrapping machines spans across several industries. Key sectors include:

-

Construction and woodworking: Protecting wooden boards, panels, and doors.

-

Automotive: Securing parts like hoods, doors, or panels during shipment.

-

Manufacturing: Wrapping large machinery components or flat-pack furniture.

-

Glass and ceramics: Safeguarding fragile products during transport.

Each industry faces unique challenges when it comes to product safety during shipment. This machine bridges that gap by providing tailored solutions for bulk and fragile products alike.

1.3 Innovative features driving demand

What sets the latest board orbital wrapping machines apart is their suite of innovations:

-

Adjustable tension control: Ensures the right balance between tight wrapping and preventing product deformation.

-

Pre-stretch technology: Maximizes film utilization, reducing costs.

-

Intuitive interfaces: Touchscreens and programmable settings simplify operation for varied product dimensions.

-

Integration capabilities: Can work seamlessly with existing conveyor belts or production lines.

Such features save time, minimize human error, and enhance overall productivity, making these machines indispensable in high-volume operations.

2. How to choose the right board orbital wrapping machine?

2.1 Key specifications to consider

Selecting the right machine can feel overwhelming, given the myriad of options available. However, focusing on these key specifications simplifies the process:

-

Maximum wrapping dimensions: Determine the largest product size the machine can accommodate.

-

Wrapping speed: Faster machines are ideal for high-volume production.

-

Film compatibility: Some machines support multiple film types, offering flexibility for different use cases.

-

Power consumption: Energy-efficient machines lower operational costs.

For example, if your business frequently ships large wooden panels, a machine with a wider wrapping capacity and faster throughput speed will be a priority.

2.2 Comparing manual vs. automated options

While manual board wrapping machines may seem cost-effective initially, automation offers unparalleled benefits in the long term:

-

Manual Machines:

-

Lower upfront cost.

-

Best suited for small-scale operations.

-

Higher dependency on operator skill.

-

Automated Machines:

-

Consistent and uniform wrapping.

-

Higher initial investment but lower long-term labor costs.

-

Ideal for large-scale, continuous operations.

Deciding between the two depends on your business scale, product types, and budget considerations.

2.3 Cost vs. efficiency: Striking the perfect balance

Cost and efficiency are often at odds when choosing equipment. While automated machines might seem expensive, they offer significant savings through reduced material waste, faster processing times, and minimal labor costs. Here's a simple breakdown:

|

Factor

|

Manual Machines

|

Automated Machines

|

|

Initial Cost

|

Low

|

High

|

|

Maintenance

|

Low

|

Moderate

|

|

Efficiency

|

Moderate

|

High

|

|

Labor Dependency

|

High

|

Low

|

Investing in an automated system often pays for itself over time, making it the smart choice for growing businesses.

3. Common challenges in board wrapping processes and their solutions

3.1 Identifying common issues

Even with the best machines, challenges in the board wrapping process can arise. Here are some of the most common issues:

-

Film tearing or breakage: This often occurs when the film tension is not properly adjusted or when low-quality film is used.

-

Uneven wrapping: This happens when the product dimensions are irregular or the machine isn’t calibrated correctly.

-

Excessive film usage: Inefficient settings or lack of pre-stretch technology can lead to unnecessary material waste.

-

Machine downtime: Poor maintenance practices can result in frequent breakdowns, halting production.

For example, a business handling irregularly sized wooden boards might face difficulty achieving uniform wrapping without precise machine adjustments.

3.2 Leveraging technology to overcome challenges

The latest board orbital wrapping machines come equipped with smart features to tackle these challenges effectively:

-

Automatic tension control: Reduces the risk of film breakage by adjusting the tension dynamically.

-

Pre-set wrapping modes: Allows operators to select a suitable mode based on product type and dimensions, ensuring even wrapping.

-

Film pre-stretch mechanisms: Extend the film's elasticity, reducing material usage while maintaining durability.

-

IoT-enabled maintenance alerts: These systems notify operators when maintenance is due, preventing unexpected downtime.

Adopting such technologies can significantly improve operational efficiency and reduce manual intervention.

3.3 Ensuring long-term efficiency and maintenance

Regular maintenance is critical to the longevity and performance of any wrapping machine. Here’s how you can ensure long-term efficiency:

-

Follow a routine maintenance schedule: Regularly clean and lubricate moving parts to prevent wear and tear.

-

Monitor film quality: Low-quality film can damage rollers and increase operational costs.

-

Train operators: Proper training ensures the machine is used to its full potential.

-

Invest in spare parts: Keep essential components on hand to minimize downtime during repairs.

By addressing these factors, businesses can maximize their ROI on board orbital wrapping machines while ensuring smooth operations.

4. Future trends in board orbital wrapping machines

4.1 Sustainability-focused advancements

As industries move toward sustainability, packaging equipment is no exception. Many manufacturers are developing eco-friendly board orbital wrapping machines that:

-

Use biodegradable films: These films break down naturally without harming the environment.

-

Optimize film usage: Advanced tension and pre-stretch technologies minimize waste.

-

Operate on renewable energy sources: Machines powered by solar or wind energy are becoming increasingly common.

For instance, a furniture company might switch to a machine that uses sustainable film, aligning its practices with customer values and reducing its carbon footprint.

4.2 AI and IoT in packaging solutions

The integration of artificial intelligence (AI) and the Internet of Things (IoT) is revolutionizing the packaging industry. Here’s how these technologies are shaping the future of board orbital wrapping machines:

-

AI for predictive analytics: Anticipates machine maintenance needs to prevent unexpected failures.

-

IoT connectivity: Enables real-time monitoring of machine performance and remote adjustments.

-

Customizable automation: Adapts wrapping techniques to specific product requirements based on data analysis.

For example, IoT-connected machines can alert operators when film rolls need replacement, eliminating guesswork and downtime.

4.3 Predictions for the next decade

The future of board orbital wrapping machines looks promising, with trends pointing toward:

-

Smarter automation: Machines capable of self-calibration and error correction.

-

Enhanced energy efficiency: Lower energy consumption without compromising performance.

-

Sustainable packaging: A shift toward reusable and recyclable materials.

These advancements will not only benefit businesses but also contribute to a more sustainable and efficient global supply chain.

Conclusion

The board orbital wrapping machine has transformed the way industries approach packaging. From ensuring product safety to improving efficiency, these machines are indispensable for modern businesses. By addressing challenges with advanced technologies and embracing sustainable practices, they continue to redefine industry standards.

For businesses looking to invest in wrapping solutions, understanding machine specifications, potential challenges, and future trends is crucial. Choosing the right machine is not just about meeting current needs—it’s about future-proofing your operations in a rapidly evolving market.

[Claim] A board orbital wrapping machine isn’t just equipment; it’s an investment in efficiency, safety, and innovation for the future of your business.