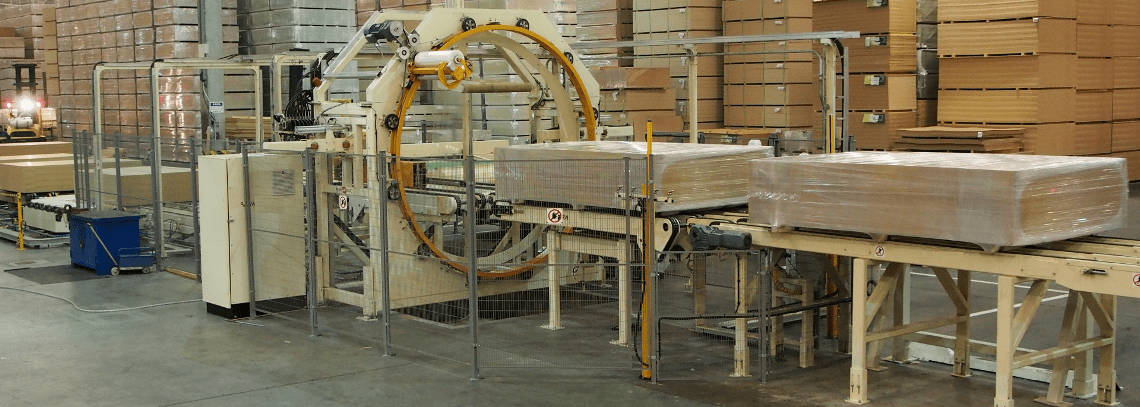

Panel Orbital Wrapping Machine

Efficient packaging solutions are vital for modern manufacturing, and the panel orbital wrapping machine has revolutionized how businesses handle large flat panels. This machine offers a streamlined, automated way to wrap products securely, ensuring they are protected during transportation and storage. Its adaptability to different materials and dimensions makes it an essential tool for industries like construction, furniture, and glass manufacturing.

The advanced technology behind orbital wrapping machines has drastically reduced labor costs, improved productivity, and enhanced the overall quality of packaging. However, understanding its features, applications, and benefits can help businesses make informed purchasing decisions, maximizing returns on investment.

As we dive deeper, this article will explore the intricate details of these machines, addressing their utility, customization options, and what to consider before purchasing. Let’s unwrap the full potential of this remarkable innovation.

[claim] Panel orbital wrapping machines are more than just packaging tools—they are transformative solutions for operational efficiency and product safety.

1. Why is a Panel Orbital Wrapping Machine an Industry Game-Changer?

1.1 Adaptability Across Industries

Panel orbital wrapping machines stand out due to their unparalleled versatility. Industries such as furniture manufacturing, glass processing, and construction rely heavily on these machines to package items of varying shapes and sizes. Unlike traditional methods, which often involve manual labor and inconsistent results, these machines deliver uniform, secure wrapping every time.

Moreover, the technology integrates seamlessly with other production line components, enhancing workflow continuity. Businesses that adopt these machines find that they are no longer constrained by packaging limitations, allowing for greater product customization and operational efficiency.

1.2 Simplifying Logistics

Packaging panels securely for transport is no small task. Orbital wrapping machines simplify this process by providing consistent tension control and protective layering. This reduces the risk of damage, which is particularly crucial when dealing with fragile or high-value items like glass panels or polished wooden boards.

This innovation also ensures that wrapped items occupy less space, lowering shipping costs and optimizing storage. Companies using these machines report fewer customer complaints related to damaged goods, leading to stronger relationships and higher customer retention rates.

1.3 Advanced Automation Capabilities

Automation is the cornerstone of any modern packaging solution, and orbital wrapping machines excel in this regard. Equipped with intelligent controls, these machines adapt wrapping speeds and patterns based on the product's specifications. This not only reduces the risk of errors but also increases overall production speed.

Businesses benefit from significant labor cost savings while ensuring that their products are wrapped to perfection every time. The integration of automation with cutting-edge features such as real-time monitoring and error detection further elevates the efficiency of the packaging process.

2. What Key Features Define the Best Orbital Wrapping Machines?

2.1 Customization for Product Variability

The best orbital wrapping machines are designed with flexibility in mind. They accommodate a wide range of panel dimensions and materials, from thin acrylic sheets to robust steel panels. This adaptability ensures that businesses can use a single machine to package diverse products, eliminating the need for multiple specialized systems.

Machines with adjustable wrapping parameters allow users to fine-tune the process based on their unique requirements. Features like customizable wrapping tension, film thickness options, and speed settings ensure optimal results for every application.

2.2 Durability and Maintenance

Longevity is a key consideration when investing in industrial equipment. High-quality orbital wrapping machines are built with durable materials that withstand continuous operation in demanding environments. These machines often include self-lubricating components and easy-to-clean designs, reducing the time and cost associated with maintenance.

Manufacturers also provide comprehensive support, ensuring that any technical issues are promptly addressed. This minimizes downtime, allowing businesses to maintain productivity levels without interruption.

2.3 Intelligent Features for Enhanced Efficiency

What sets the best machines apart is their integration of smart technology. From touch-screen interfaces to IoT-enabled monitoring systems, these features provide real-time insights into the wrapping process. Operators can track performance metrics, detect errors, and make adjustments on the fly, ensuring consistent output.

Additionally, many modern machines come equipped with eco-friendly modes, allowing businesses to reduce material wastage and energy consumption. This not only cuts costs but also aligns with sustainability goals, an increasingly important consideration for businesses today.

3. How Can You Tailor a Panel Orbital Wrapping Machine to Your Needs?

3.1 Modular Design for Maximum Flexibility

The modular design of panel orbital wrapping machines is one of their most appealing features. These machines can be customized to fit specific operational needs, whether it’s handling oversized panels or working with specialized wrapping materials. This flexibility ensures that businesses can achieve optimal packaging results without investing in multiple machines.

For example, companies in the glass industry might require features like soft-start mechanisms to protect fragile panels, while those in furniture manufacturing might prioritize adjustable tension controls for wrapping large wooden boards. Modular upgrades such as extended conveyors or additional rollers further enhance the machine’s adaptability.

3.2 Enhanced Safety Features

Safety is paramount in any industrial setting, and panel orbital wrapping machines are equipped with advanced features to protect both operators and products. Sensors detect irregularities, such as improperly positioned panels, and halt the operation to prevent accidents.

These machines also feature protective barriers and emergency stop functions, ensuring a safe working environment. Businesses can further enhance safety by integrating automated feeding systems, reducing the need for manual intervention.

3.3 Tailored Software for Precision Control

Customizable software is another critical feature, allowing operators to fine-tune wrapping parameters to meet specific needs. Whether adjusting wrapping speed, layering thickness, or film overlap, these machines provide precise control over every aspect of the packaging process.

Software interfaces are often user-friendly, featuring touchscreens that display key metrics such as wrapping cycles and material usage. Advanced models even include remote monitoring capabilities, enabling operators to oversee the process from a centralized control room.

4. What Are the Long-Term Benefits of Investing in This Technology?

4.1 Reduced Material Costs

One of the most significant advantages of using panel orbital wrapping machines is the reduction in material waste. These machines are designed to optimize film usage, ensuring that only the necessary amount is applied to each panel.

Over time, this results in substantial savings, especially for businesses with high packaging volumes. Additionally, the ability to use thinner, more cost-effective wrapping films further contributes to cost reduction.

4.2 Improved Brand Reputation

A well-wrapped product not only ensures safe delivery but also leaves a lasting impression on customers. Consistent and professional packaging enhances brand reputation, signaling to clients that the company values quality and attention to detail.

Many businesses report increased customer satisfaction and repeat orders after adopting these machines. By minimizing packaging errors and damage during transit, companies can build stronger, more reliable partnerships with their clients.

4.3 Sustainability and Energy Efficiency

In today’s environmentally conscious market, sustainability is a priority for most businesses. Modern orbital wrapping machines incorporate eco-friendly features, such as energy-efficient motors and recyclable film options.

These innovations reduce the carbon footprint of packaging operations, aligning with global sustainability goals. Additionally, the ability to integrate renewable energy sources, such as solar panels, into the machine’s power supply further underscores its environmental benefits.

Conclusion

The panel orbital wrapping machine is not just a tool; it is a transformative solution that redefines packaging efficiency and product safety. From its adaptability to its advanced automation capabilities, this machine offers unparalleled benefits for businesses in various industries.

[claim] By investing in a panel orbital wrapping machine, companies not only streamline their operations but also set themselves up for long-term success in a competitive market.