Orbital Wrapping Machine for Sale

In today’s fast-paced world of logistics and packaging, an orbital wrapping machine has become an essential asset for many industries, from manufacturing to shipping. These machines offer a practical solution for wrapping goods quickly, efficiently, and securely, making them a sought-after tool in both small and large-scale operations. As the demand for optimized packaging solutions grows, orbital wrapping machines are becoming a game-changer. Whether you're looking to streamline operations or reduce material waste, investing in an orbital wrapping machine can offer your business numerous advantages.

When it comes to packaging, the wrapping process plays a pivotal role in product protection, aesthetics, and efficiency. Unlike traditional methods, orbital wrapping machines provide a continuous, automated way of wrapping goods with stretch film. This technology reduces labor costs, improves consistency, and ensures that products are tightly wrapped for maximum security. With varying models available, from simple manual to fully automated systems, there’s an orbital wrapping machine suitable for every type of business, whether you're a small retailer or a large-scale manufacturer.

The growing interest in these machines stems from their versatility, ease of use, and the ability to integrate with existing packaging lines. It’s important to consider several factors before making a purchase. For instance, the type of product you're wrapping, the required wrapping speed, and the durability of the stretch film can all influence which orbital wrapping machine is the best fit for your needs. Whether you need to wrap pallets, rolls, or individual products, these machines provide a customizable solution that meets your specific requirements.

When considering an orbital wrapping machine for sale, you may have many questions: What makes one model stand out over another? How do you determine the right size and features? And, most importantly, what should you expect from the machine in terms of performance and longevity? In this article, we’ll address these questions, provide a thorough comparison of available models, and help you navigate the process of selecting the ideal orbital wrapping machine for your business.

1. What Is an Orbital Wrapping Machine?

1.1 What does an orbital wrapping machine do?

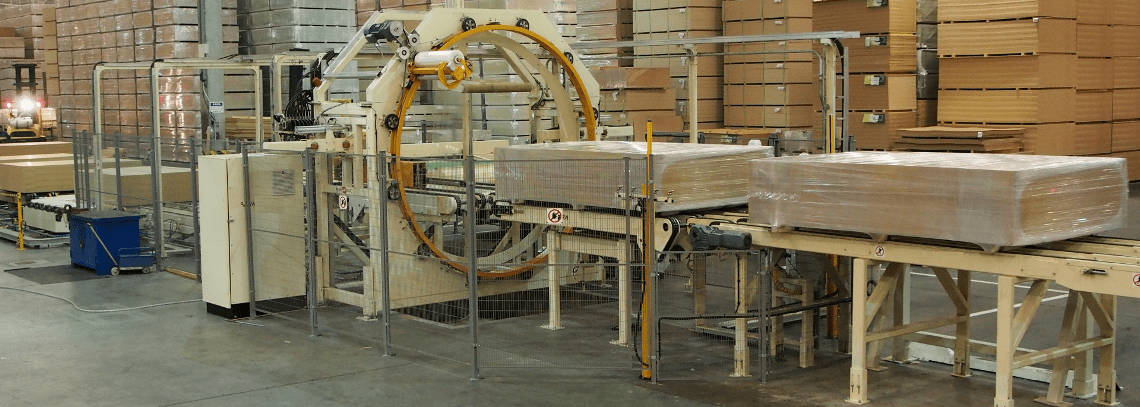

An orbital wrapping machine is a high-efficiency packaging tool designed to wrap products with stretch film using an automated process. Unlike traditional wrap machines that apply film from one direction, orbital machines work by rotating around the product, wrapping it continuously in a spiral pattern. This allows for uniform wrapping, which ensures that each product is securely and tightly wrapped for protection during storage and transit.

These machines are especially useful for wrapping large or heavy items that need to be securely wrapped with minimal manual intervention. For example, they can wrap pipes, coils, furniture, and even large appliances. The machine's design allows it to wrap both the top and bottom of the product, as well as the sides, providing a complete protective layer that holds the item in place.

1.2 How does an orbital wrapping machine work?

Orbital wrapping machines work on a simple but effective principle: the product is placed on a rotating platform, while the machine's arm moves around it, dispensing stretch film in multiple layers. As the product rotates, the film is stretched and applied under tension, which ensures a tight, secure wrap.

The key component of this process is the orbital arm, which can be adjusted based on the product's size. The machine's system automatically adjusts the tension of the film, ensuring a consistent wrap every time. In addition, orbital wrapping machines are equipped with features that allow operators to control the speed and number of layers of film applied, providing flexibility to accommodate different types of products and packaging needs.

1.3 Why choose an orbital wrapping machine over other types of wrapping machines?

Choosing an orbital wrapping machine over other types of machines offers several advantages. First and foremost, it provides better consistency and speed compared to manual wrapping methods. Since the machine is automated, it can wrap products in a fraction of the time it would take a human to do the same job, reducing labor costs and improving throughput.

Orbital wrapping machines are also known for their ability to apply more layers of film with less material wastage. The continuous film wrapping process reduces the amount of unused film, making it a more cost-effective solution for businesses looking to save on packaging materials.

Additionally, the tight, secure wrap created by these machines ensures that products are better protected against damage during transit. This level of protection is especially critical for fragile items or those with irregular shapes, as the wrap keeps them in place and prevents shifting.

2. How to Choose the Best Orbital Wrapping Machine for Sale?

2.1 What are the key features to look for when buying an orbital wrapping machine?

When shopping for an orbital wrapping machine, there are several key features to consider to ensure you're selecting the best one for your business. Some of the most important factors include:

-

Wrap Speed: The machine's wrapping speed determines how quickly it can wrap products. If you're operating in a high-volume environment, a machine with a higher wrapping speed will be more efficient.

-

Film Tension Control: Look for a machine with adjustable film tension. This feature ensures that the film is applied tightly, but without over-stretching it, which can waste material.

-

Size Compatibility: Ensure the machine can handle the size and shape of the products you're wrapping. Some models are designed for smaller items, while others can wrap large, irregularly shaped goods.

-

Automation Features: Depending on your needs, you may want a fully automatic model that requires minimal operator intervention. These models can integrate into existing packaging lines and offer high levels of productivity.

-

Durability and Maintenance: A machine that is built to last will provide you with better long-term value. Look for machines with easy-to-maintain parts and strong construction that can handle heavy use.

2.2 Should you opt for a manual or automatic orbital wrapping machine?

The decision between a manual and an automatic orbital wrapping machine depends on several factors, including your production volume, budget, and labor availability.

-

Manual Orbital Wrapping Machines: These models require more operator involvement. The operator needs to position the product and initiate the wrapping process. While they are often more affordable, manual machines are best suited for small to medium-sized businesses with lower wrapping demands.

-

Automatic Orbital Wrapping Machines: These machines offer a higher degree of automation, requiring little to no human intervention. They can be integrated into larger production lines, wrapping products automatically as they are placed on the conveyor. Automatic models are ideal for high-volume operations, as they save time and reduce the potential for human error.

2.3 What are the considerations for wrapping different product sizes and shapes?

One of the main advantages of orbital wrapping machines is their versatility. These machines can be adapted to wrap a wide range of products, from cylindrical items like pipes to irregularly shaped products such as furniture. However, it’s important to consider a few things when selecting a machine for varying product sizes and shapes:

-

Adjustable Arm Length: Ensure the machine features an adjustable arm to accommodate different sizes of products. Some models come with extendable arms, while others allow you to adjust the speed and rotation pattern to suit the product.

-

Customization: Some orbital wrapping machines can be customized to apply film in specific patterns or layers. This customization is particularly useful when wrapping products with unique dimensions or those that require special attention to detail.

-

Product Positioning: The product's orientation on the platform can also impact how effectively the machine wraps it. Some models feature an adjustable product placement system, allowing operators to position items based on their size and shape for optimal wrapping.

3. What Are the Benefits of Using an Orbital Wrapping Machine?

3.1 How does an orbital wrapping machine improve operational efficiency?

Orbital wrapping machines significantly enhance operational efficiency in several ways. First, their automated nature eliminates much of the manual labor involved in wrapping products. By minimizing human input, these machines free up valuable time for workers to focus on other tasks, which ultimately increases overall productivity.

Unlike manual wrapping, which can be inconsistent and time-consuming, an orbital machine applies a uniform layer of stretch film around each product. This ensures that every item is securely wrapped with precision, helping to reduce errors and the need for rework. Additionally, the continuous wrapping process significantly speeds up the packaging cycle. For businesses handling large volumes of goods, this increase in speed can result in significant time and cost savings.

Beyond just wrapping speed, orbital wrapping machines help maintain product integrity by securely binding items without the risk of slippage. When products are packed tightly and consistently, they are far less likely to be damaged during handling, storage, or transport. This, in turn, reduces the chances of costly product returns and boosts customer satisfaction.

3.2 What impact does an orbital wrapping machine have on packaging costs?

One of the most attractive features of orbital wrapping machines is their ability to lower overall packaging costs. This cost reduction is achieved in several key ways.

-

Less Material Waste: Orbital wrapping machines use film more efficiently. The continuous wrapping motion applies the film in a tightly controlled manner, minimizing waste. This is particularly beneficial for companies that use large volumes of stretch film, as even slight reductions in material usage can add up over time.

-

Long-Term Durability: While the initial investment in an orbital wrapping machine can be significant, the durability and efficiency of these machines often lead to substantial long-term savings. They are designed to withstand heavy use, reducing the frequency of repairs and the cost of replacement parts.

-

Fewer Labor Costs: Since orbital wrapping machines automate the wrapping process, fewer workers are needed to oversee packaging operations. Labor costs can be reduced significantly, especially in high-volume operations where manual wrapping would require a large team to keep up with production demands.

In addition, orbital machines help reduce the costs of handling and storing packaging materials. With their precise wrapping method, these machines ensure that products are wrapped tightly and securely, reducing the need for additional padding or cushioning material that would typically be needed in more traditional packaging methods.

3.3 How can an orbital wrapping machine boost product security?

Product security is a critical concern, especially for high-value or fragile items. Orbital wrapping machines play an essential role in safeguarding products during storage and transport. Here’s how they contribute to better security:

-

Tighter, More Secure Wrap: One of the standout features of orbital wrapping machines is the ability to apply tight, even layers of stretch film around products. The film adheres firmly to the product, preventing shifting and reducing the risk of damage. This is especially important for irregularly shaped or delicate items that could be easily dislodged during handling.

-

Protection from External Elements: The stretch film used in orbital wrapping acts as a protective barrier against moisture, dust, dirt, and even UV light. This makes it ideal for industries that ship goods in varying environmental conditions, ensuring that products arrive at their destination in the same condition they were packed in.

-

Tamper-Evident Security: In some models, the film can be enhanced with tamper-evident features, which offer additional security. This feature makes it clear if the wrap has been disturbed, providing peace of mind that the product has remained secure throughout its journey.

Orbital wrapping machines not only protect products from damage, but they also serve as a deterrent to theft and tampering, adding an extra layer of security in transit.

4. What Are the Key Factors to Consider When Purchasing an Orbital Wrapping Machine?

4.1 What is the ideal price range for an orbital wrapping machine?

The price of an orbital wrapping machine can vary significantly based on factors such as size, functionality, and automation level. For a basic, manual model, you might expect to pay between $5,000 and $10,000. These models are typically suited for small-scale operations with lower wrapping demands.

On the other hand, fully automated orbital wrapping machines, which offer higher speeds and more advanced features, can cost anywhere from $20,000 to $50,000 or more. The price also depends on whether you choose a stand-alone unit or one that is integrated into a larger packaging line. For businesses that handle high volumes or require customized features, investing in a more expensive model can pay off in the long term by improving throughput and reducing labor costs.

4.2 What additional costs should you consider when purchasing an orbital wrapping machine?

While the upfront cost is a significant factor, there are several additional costs associated with purchasing and maintaining an orbital wrapping machine. These include:

-

Installation Fees: Many orbital wrapping machines require professional installation, especially if they are being integrated into an existing packaging line. Installation fees can range from a few hundred to several thousand dollars, depending on the complexity of the system.

-

Maintenance and Repairs: Like any machine, orbital wrapping machines require regular maintenance to keep them in optimal condition. Maintenance costs can include the price of replacement parts, lubricants, and the services of technicians for repairs and troubleshooting.

-

Training Costs: If you're introducing orbital wrapping machines into your operations for the first time, there may be training costs for your team. Many manufacturers offer training programs to help operators understand how to use the machine properly and safely.

When budgeting for an orbital wrapping machine, it’s crucial to factor in these ongoing costs to ensure you're prepared for the total cost of ownership.

4.3 How to ensure the machine fits with your existing workflow?

Before purchasing an orbital wrapping machine, it’s important to consider how the machine will fit into your existing workflow. Here are a few questions to ask:

-

Will the machine integrate with my current packaging line? If you already have a packaging line in place, you'll want to ensure that the orbital wrapping machine can be easily integrated. Some models are designed to work seamlessly with conveyor systems, while others may require more modification.

-

Is there adequate space for the machine? Orbital wrapping machines require a certain amount of space for operation, especially if they are larger, automated models. Measure the area where the machine will be placed and ensure that there is enough room for both the machine and the products it will be wrapping.

-

How will the machine handle my current production volume? Ensure that the orbital wrapping machine you choose is capable of meeting your production demands. If your business handles high volumes, you may need a machine with higher wrapping speeds and more automation.

Taking the time to assess how the orbital wrapping machine fits into your existing infrastructure will help avoid operational disruptions and ensure that the machine enhances your production capabilities.

Conclusion

Orbital wrapping machines have proven to be an indispensable tool for businesses looking to improve packaging efficiency, reduce material waste, and ensure product security. Their automated nature, combined with the ability to handle a wide variety of products, makes them a versatile solution for industries ranging from manufacturing to retail. With features that allow for customization, reduced material costs, and enhanced sustainability, these machines offer a win-win for both businesses and the environment.

When purchasing an orbital wrapping machine, it’s important to consider factors such as speed, size compatibility, and automation level. Investing in the right machine can lead to significant cost savings, improve operational efficiency, and reduce labor requirements. Additionally, regular maintenance and a focus on sustainability will help maximize the machine's lifespan and benefit your company in the long run.

For businesses looking to stay ahead in a competitive market, purchasing an orbital wrapping machine can provide an essential edge—offering better packaging, improved cost-effectiveness, and enhanced security, all while supporting a more sustainable approach to packaging.