Orbital Wrapping Machine Price

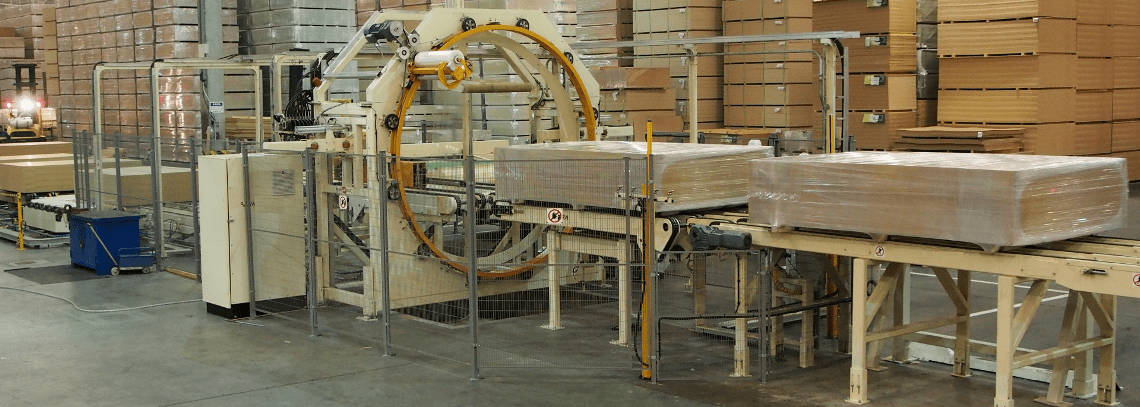

When it comes to packaging solutions, the orbital wrapping machine stands out as an essential tool for industries that require efficient and secure packaging of products. Whether it's for wrapping large machinery, industrial products, or palletized goods, the orbital wrapping machine ensures that items are tightly secured with a stretch film, offering protection from environmental factors like dust, moisture, and scratches. But with a variety of models and features available, the price of an orbital wrapping machine can vary significantly.

Understanding the price range of these machines is key for businesses planning to invest in one. The cost can depend on a number of factors, including machine size, features, and even the brand. Additionally, service and maintenance costs, as well as the cost of replacement films, are factors that should not be overlooked. Before making a purchase, it's essential to weigh both the initial investment and long-term operational costs to determine if an orbital wrapping machine is the right solution for your business.

Determining the cost of an orbital wrapping machine isn’t a straightforward process. Many businesses, especially smaller ones, might find themselves wondering if the initial investment is justified. After all, there are cheaper alternatives available, but how do they compare when it comes to durability, efficiency, and overall value? In this article, we'll delve into the factors influencing orbital wrapping machine prices and explore the best options based on different needs and budgets.

Claim: The price of orbital wrapping machines can vary based on several factors including size, capabilities, and functionality. However, by evaluating these aspects carefully, businesses can make an informed decision that balances both cost-effectiveness and operational efficiency.

1. What Factors Affect the Price of Orbital Wrapping Machines?

The price of orbital wrapping machines can be influenced by a variety of factors that businesses need to consider before making a purchase. From the type of machine to its capabilities, several elements contribute to the overall cost.

1.1 Size of the Machine and Wrapping Capacity

The size of the orbital wrapping machine plays a major role in its price. Larger machines capable of wrapping bigger or heavier loads typically cost more due to the increased complexity of their design and the higher quality materials required for their construction. Machines with higher load capacities often come with more powerful motors and robust frames to ensure safe operation. The cost increases as the wrapping capacity grows, particularly for machines designed to handle heavier industrial products.

In addition to size, the machine's wrapping capacity also influences its price. Machines capable of wrapping pallets or large items with thicker stretch films or multiple layers are generally more expensive due to their additional features and enhanced capabilities.

1.2 Brand and Quality of Manufacturing

The brand of the orbital wrapping machine also affects its price. Renowned manufacturers that offer high-quality, durable machines tend to charge a premium for their products. These brands have established reputations for providing reliable, long-lasting equipment with advanced features. A higher price tag often reflects better construction, superior performance, and customer support services, making them a popular choice for businesses willing to invest in long-term solutions.

On the other hand, lesser-known brands might offer more affordable machines, but they might lack the same level of reliability or customer support. In these cases, the lower price could come with the risk of higher maintenance costs and shorter machine lifespans.

1.3 Additional Factors Influencing Price

In addition to size and brand, there are several other factors that contribute to the price of orbital wrapping machines. These include the materials used in the construction of the machine, the complexity of the technology incorporated (such as automation or remote control features), and any added functionalities. Machines equipped with advanced controls, sensors, or energy-saving mechanisms can significantly increase the price.

The location of purchase also plays a role in pricing. Regional manufacturers might offer more competitive pricing, but international shipping and tariffs could increase the total cost of the machine.

2. How Do Different Brands Influence the Price?

Branding can make a significant difference when it comes to the price of an orbital wrapping machine. Reputable brands in the packaging industry often have a higher price tag due to their extensive research and development, quality control, and after-sales support.

2.1 Leading Brands and Their Market Position

Some of the leading brands in the orbital wrapping machine market include names like Lantech, Macon, and Signode. These brands have built a reputation over decades of providing reliable, high-quality machines that cater to various industries, including logistics, food and beverage, and manufacturing. As a result, their machines tend to be priced at a premium.

Lantech, for example, is known for its robust and customizable orbital wrapping machines that can be tailored to the specific needs of the customer. However, this level of customization and quality comes at a higher cost.

2.2 Price Range of Top-Tier Brands

Top-tier brands like Lantech and Signode typically offer orbital wrapping machines that range from $15,000 to $60,000, depending on the machine's size, features, and capabilities. The more advanced models with high throughput, automated film tension control, and custom configuration options tend to fall on the higher end of this spectrum. These machines are built for heavy-duty industrial use, providing long-term reliability and lower maintenance needs.

On the other hand, some mid-range brands offer machines that provide similar functionality but at a lower price point, usually ranging from $8,000 to $20,000. These machines are often more suitable for smaller businesses or lower-volume operations.

2.3 Lesser-Known Brands and Their Pricing

While premium brands dominate the high-end market, there are also lesser-known or emerging brands offering orbital wrapping machines at a fraction of the cost. These machines might not come with all the bells and whistles of premium models, but they can still offer reliable performance for businesses with less demanding packaging needs.

Lesser-known brands typically offer machines in the $5,000 to $10,000 range, making them an attractive option for small businesses looking to invest in packaging equipment without breaking the bank. However, it's important to carefully evaluate the build quality and performance of these machines to ensure they meet your operational requirements.

3. What Are the Key Features That Impact Price?

The price of an orbital wrapping machine is closely tied to the features it offers. Businesses should carefully assess their needs to determine which features are essential and which ones can be sacrificed to stay within budget.

3.1 Automation and Control Features

One of the key features that can significantly impact the price is the level of automation available. Machines with automated controls, such as programmable settings for film tension, speed, and wrapping patterns, can make the wrapping process more efficient, saving both time and labor costs.

Machines equipped with touch-screen controls, sensors for load detection, and programmable wrap cycles often come at a higher price due to the advanced technology they incorporate. These automation features are especially valuable for businesses with high-volume packaging needs, as they reduce human error and increase productivity.

3.2 Durability and Construction Materials

The durability of the orbital wrapping machine is another important consideration. Machines made from high-quality steel or stainless steel tend to last longer and require less maintenance. The choice of materials affects not only the machine's lifespan but also its ability to handle demanding environments.

Machines designed for outdoor use or in harsh environments often feature corrosion-resistant coatings, weatherproofing, and reinforced frames, all of which add to the overall cost. However, for businesses that require a rugged machine for industrial settings, this added investment can prove worthwhile in the long run.

3.3 Energy Efficiency and Environmental Impact

As energy efficiency becomes an increasing concern for businesses, many orbital wrapping machine manufacturers are incorporating energy-saving technologies. Machines that feature energy-efficient motors, low-energy consumption, and recyclable film options may carry a higher upfront cost but can lead to long-term savings in utility bills and environmental impact.

Energy-efficient machines may come with a higher price tag, but for companies focused on sustainability or trying to reduce operational costs, the investment can pay off quickly.

4. Is the Price of an Orbital Wrapping Machine Worth the Investment?

When considering the purchase of an orbital wrapping machine, the main question that arises is: Is it worth the investment? This question isn’t always easy to answer since the decision hinges on several factors, including the nature of your business, the volume of products you need to wrap, and your long-term goals.

4.1 The Long-Term Benefits of Orbital Wrapping Machines

For businesses that handle large volumes of products, investing in an orbital wrapping machine is often a game-changer. The primary benefit is the significant increase in efficiency. Unlike manual wrapping methods, which require labor-intensive processes, orbital wrapping machines can wrap products quickly and with consistency. This increases throughput, which in turn allows your business to meet growing demand while keeping costs under control.

The automation of wrapping also reduces the risk of human error. When wrapped by hand, items are more likely to be improperly secured, leading to potential damage during transit. Orbital wrapping machines ensure uniformity and secure wrapping, which minimizes the chances of damage and reduces returns. Additionally, many models come with features that automatically adjust film tension and wrapping patterns, ensuring that every package is wrapped precisely the same way.

Another advantage is the labor savings. Orbital wrapping machines can significantly reduce the number of workers needed for wrapping tasks, freeing them up for other essential duties. Even if you're using the machine in a relatively low-volume environment, the cost of the machine may be quickly offset by the hours saved in labor. This is especially valuable in industries where labor costs are high or in businesses that are looking to streamline their operations.

4.2 Calculating the Return on Investment (ROI)

The decision to buy an orbital wrapping machine should come with a calculated expectation of ROI. While the initial cost might seem daunting, it's essential to look at the bigger picture. ROI can be calculated by considering the machine’s impact on productivity, labor savings, reduced material waste, and decreased product damage.

For example, if you were previously paying a team of workers to manually wrap products, the machine will likely save on those labor costs over time. Even more, an orbital wrapping machine can reduce stretch film waste by applying the optimal amount of film to each package, which is a cost-saving measure in itself. Additionally, having properly wrapped products means a reduced chance of returns due to damage, which can save your business even more money.

The payback period for orbital wrapping machines is often between 1 to 3 years, depending on the volume of use. After this period, the machine effectively becomes a source of continuous savings, contributing to the overall profitability of your business.

4.3 Hidden Costs and Considerations

While the benefits are clear, businesses need to account for any hidden costs associated with owning an orbital wrapping machine. The initial purchase price is just the tip of the iceberg. Ongoing costs include maintenance, repairs, and replacement parts, such as the stretch film used in wrapping. Depending on the machine model, these costs can add up over time.

Additionally, some businesses might need to factor in the cost of training staff to operate the machine, especially if it's an advanced model with automation features. Training can take time and might require professional help, which could add to the overall investment.

Another consideration is the cost of servicing the machine. Many manufacturers offer maintenance contracts, but not all businesses opt to purchase them. However, opting out might lead to higher repair costs or longer downtime if the machine breaks down unexpectedly.

Conclusion

In conclusion, the price of an orbital wrapping machine is not just about the initial investment but also about the long-term value it provides. While the cost can range widely depending on features, brand, and machine size, businesses that require high-volume wrapping will often find that the machine pays for itself in a relatively short period. From labor savings to reduced product damage and increased productivity, the benefits of an orbital wrapping machine are undeniable.

However, it's crucial to carefully assess the specific needs of your business and ensure that the machine you purchase aligns with your operational requirements. Whether you're investing in a top-tier model from a leading brand or opting for a more affordable option, the right orbital wrapping machine can significantly enhance your packaging process.

Claim: The decision to purchase an orbital wrapping machine should be backed by a detailed assessment of both its initial cost and the long-term savings it offers. The right machine, when chosen correctly, can become a crucial asset for any business involved in high-volume packaging.