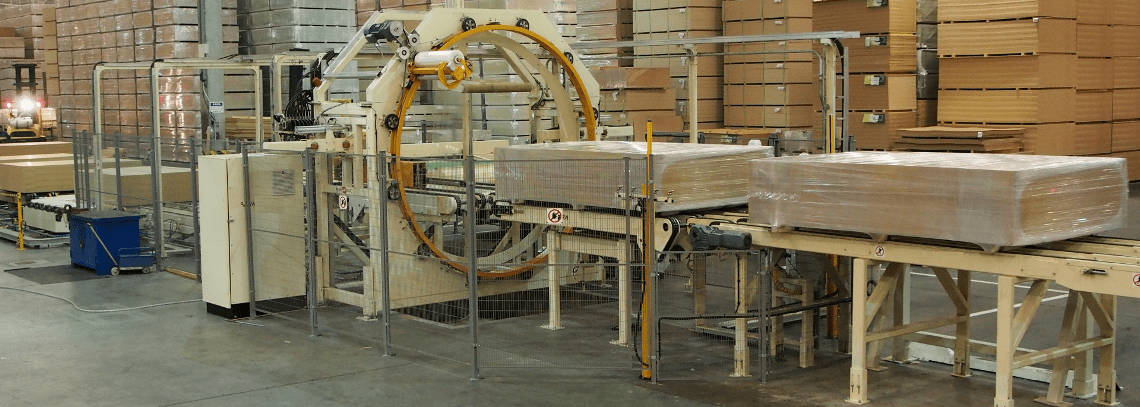

Horizontal Orbital Wrapping Machine

It was a busy day in the warehouse, the kind where every second counts, and the pressure to streamline operations is always on. We were about to test a new horizontal orbital wrapping machine. For weeks, our team had been reviewing options, debating features, and trying to find a solution that would enhance both efficiency and safety. This machine, we hoped, would be the answer to reducing the time spent manually wrapping products, while also improving the overall durability of the packaging. After all, the stakes are high in the packaging world: damaged goods cost money, but so does inefficiency.

After setting up the machine and initiating the test, we were struck by how smoothly it operated. The horizontal wrapping mechanism seemed to work seamlessly, offering a great balance of speed and precision. But I couldn't help but wonder: What makes these machines so effective in the first place? Why are so many businesses investing in orbital wrapping solutions?

The benefits were clear in our initial trial, but it prompted me to look deeper into the mechanics, features, and real-world advantages of a horizontal orbital wrapping machine. This isn't just a piece of equipment; it's a game-changer for industries that rely on reliable and secure packaging.

Claim: The horizontal orbital wrapping machine’s ability to consistently deliver high-quality wraps, coupled with its efficiency, makes it a valuable investment for any packaging-heavy industry.

1. What Makes a Horizontal Orbital Wrapping Machine So Efficient?

1.1 The Unmatched Speed and Consistency of Horizontal Wrapping

I remember the first time I saw the machine in action. It was as though the wrapping process had been turned into an art form, a seamless blend of speed and precision that left no room for error. Horizontal wrapping machines are designed to wrap items quickly, but more importantly, they do so consistently. The speed allows for high throughput, and the precision ensures that each wrap is identical—every time. This type of consistency is crucial, especially for industries like food packaging, where quality control is non-negotiable.

In a bustling warehouse, time is a commodity, and it can be the difference between making a deadline or falling behind. The horizontal orbital wrapping machine cuts down on the time it takes to wrap goods, offering a faster alternative to manual methods. This efficiency translates into higher productivity, and in turn, a more streamlined operation.

1.2 Improving Operational Flow with Less Labor

In many industries, the labor required for wrapping goods is a substantial cost. With the horizontal orbital wrapping machine, this issue is addressed head-on. The machine reduces the number of hands needed to complete the task and eliminates the need for manual labor-intensive steps. For example, workers no longer have to manually wrap each item with plastic or tape, and there’s no need for tedious adjustments during the wrapping process. This automation frees up workers for other tasks, making better use of their time and energy.

When you think about the labor savings alone, the return on investment (ROI) for these machines becomes apparent. The machine’s ability to handle the task autonomously increases both operational efficiency and employee satisfaction. Less manual work means less fatigue and fewer opportunities for human error, which in turn enhances the overall productivity of the workforce.

2. How Does the Technology Behind Horizontal Orbital Wrapping Work?

2.1 The Core Components of a Horizontal Orbital Wrapping System

To truly understand why these machines are so effective, it’s essential to break down how they work. The horizontal orbital wrapping machine uses a combination of advanced technology to wrap products efficiently. At its core, the system consists of a rotating arm that orbits around the product, applying film in a circular motion. The machine typically operates with adjustable speed controls, allowing operators to fine-tune the wrapping process to suit the size and nature of the item being wrapped.

Another key element is the film tension control system. This ensures that the film is applied evenly, without wrinkles or gaps, guaranteeing that the wrap is tight and secure. The wrapping arm is often made of durable materials designed to handle heavy-duty use, making it ideal for both small and large-scale packaging operations.

2.2 The Precision of Automated Wrapping Technology

What truly sets the horizontal orbital wrapping machine apart is its level of automation. The automation behind the wrapping process allows for exceptional precision, ensuring that the film is applied uniformly without the need for manual intervention. This is crucial in industries where the stability and protection of the wrapped goods are paramount. For instance, fragile products, such as glass or delicate electronics, require the wrapping to be applied in such a way that it offers full protection during transit.

When I first witnessed the machine in action, it was astonishing to see how the orbital wrapping process automatically adjusted to different product sizes. The sensor technology built into the system allows it to detect variations in product dimensions and adapt the wrapping accordingly. This level of responsiveness ensures that the machine can work with a broad range of products, from small boxes to large industrial equipment, without compromising on wrapping quality.

2.3 The Role of Smart Controls in Modern Machines

As the demand for smarter, more efficient solutions grows, horizontal orbital wrapping machines have kept pace with these advancements. Many modern models come equipped with smart controls that allow for real-time monitoring and adjustments. This technology connects the machine to a central management system, enabling operators to track performance metrics, detect maintenance issues, and even adjust settings remotely.

In industries where uptime is critical, the ability to remotely monitor machine performance can significantly reduce downtime. For example, if an issue arises with the film tension or wrapping arm, the machine can alert the operator, who can then make adjustments or call for service. This feature is particularly useful in environments that operate 24/7, where quick response times are essential to maintaining production schedules.

3. What Are the Cost Benefits of Investing in a Horizontal Orbital Wrapping Machine?

3.1 Reducing Packaging Material Waste

One of the most immediate benefits of investing in a horizontal orbital wrapping machine is the reduction in packaging material waste. Traditional wrapping methods often involve excess film, with workers having to manually trim and adjust wraps to fit the products. This not only wastes materials but also drives up costs. In contrast, orbital wrapping systems are engineered to apply the exact amount of film needed, minimizing waste. The film is applied tightly and uniformly, ensuring that every inch of material is utilized effectively.

The machine’s film tension control system plays a significant role here. It ensures that the wrap is applied evenly and securely, without overuse of materials. Over time, this precision can lead to significant savings on packaging materials, making it a highly cost-effective investment. Not only does it help reduce material costs, but it also helps businesses meet sustainability goals by minimizing waste.

3.2 Lowering Labor and Operational Costs

While the upfront cost of a horizontal orbital wrapping machine can be a significant investment, the long-term savings it offers are undeniable. The automation of the wrapping process reduces the need for manual labor, which lowers labor costs over time. In fact, with fewer workers needed to operate the wrapping station, businesses can reallocate their workforce to higher-value tasks that require more skill or attention.

Additionally, the reduced need for manual labor can decrease human error, which often leads to costly mistakes, such as improperly wrapped products or wasted materials. The reduction in errors alone can offset much of the initial cost of the machine. Furthermore, many of these machines are designed to run continuously with minimal downtime, making them ideal for high-volume operations. This constant, reliable operation maximizes the productivity of the entire packaging process.

3.3 Improving Return on Investment Through Enhanced Efficiency

When considering the ROI of a horizontal orbital wrapping machine, it's important to look beyond the direct cost savings. Efficiency improvements translate into faster throughput, which means more units can be wrapped in less time. In a fast-paced industry like ours, where time equals money, this increase in throughput can result in a significant competitive advantage.

Moreover, the increased efficiency also reduces the strain on other equipment in the packaging line. When one part of the process speeds up, it often creates a ripple effect, enabling the entire system to operate at a higher level of efficiency. In some cases, businesses may be able to reduce their reliance on other types of equipment or infrastructure, further decreasing operational costs.

4. How Can a Horizontal Orbital Wrapping Machine Improve Workplace Safety?

4.1 Enhancing Worker Safety with Automation

When we first switched to using the horizontal orbital wrapping machine, one of the most noticeable improvements was in the safety of our workplace. In traditional wrapping methods, workers would often have to physically handle heavy rolls of plastic wrap and position them manually, sometimes in awkward postures. The risk of injury, particularly musculoskeletal strain or repetitive motion injuries, was significant.

With the automation offered by the horizontal orbital wrapping machine, the need for manual handling is virtually eliminated. Workers no longer have to lift heavy rolls of film or move items around to get them wrapped. The machine takes care of these tasks, reducing the physical strain on employees and improving workplace ergonomics. In turn, this contributes to fewer workplace injuries and greater employee well-being.

4.2 Minimizing Risk of Workplace Accidents

The horizontal orbital wrapping machine is also equipped with safety features designed to reduce the risk of accidents in the workplace. Features such as emergency stop buttons, protective shields, and sensors that detect human presence around the machine help ensure that workers are not exposed to unnecessary risks. These safety measures are crucial, especially in high-volume environments where the potential for accidents is heightened.

By minimizing these risks, the machine creates a safer work environment, which is not only important for worker health but also for compliance with safety regulations. In industries where safety violations can result in fines or legal consequences, having a machine with these built-in protections is a smart move.

4.3 Promoting a Safer, More Efficient Workflow

The safety of workers isn’t the only benefit; the horizontal orbital wrapping machine also helps improve workflow efficiency. When employees don’t have to worry about manual wrapping tasks, they can focus on higher-priority jobs that require their attention. This leads to fewer distractions and a smoother workflow across the entire packaging line. Additionally, the machine’s consistency in wrapping ensures that products are handled with the utmost care, which reduces the chances of damaged goods—another safety concern that can arise when products are mishandled or improperly wrapped.

With fewer accidents and less manual labor involved, the overall safety and efficiency of the operation improve. The machine’s automated process frees up workers to engage in tasks that require problem-solving or decision-making, ultimately raising the overall productivity and safety of the workplace.

Conclusion

Horizontal orbital wrapping machines are more than just a tool for wrapping products; they represent a shift towards greater efficiency, cost-effectiveness, and safety in the workplace. From minimizing material waste to improving labor costs and ensuring the safety of employees, the benefits are clear. As industries continue to grow and evolve, the demand for smarter, more automated solutions will only increase. Investing in a horizontal orbital wrapping machine is not just an investment in equipment; it’s an investment in the future of the business.