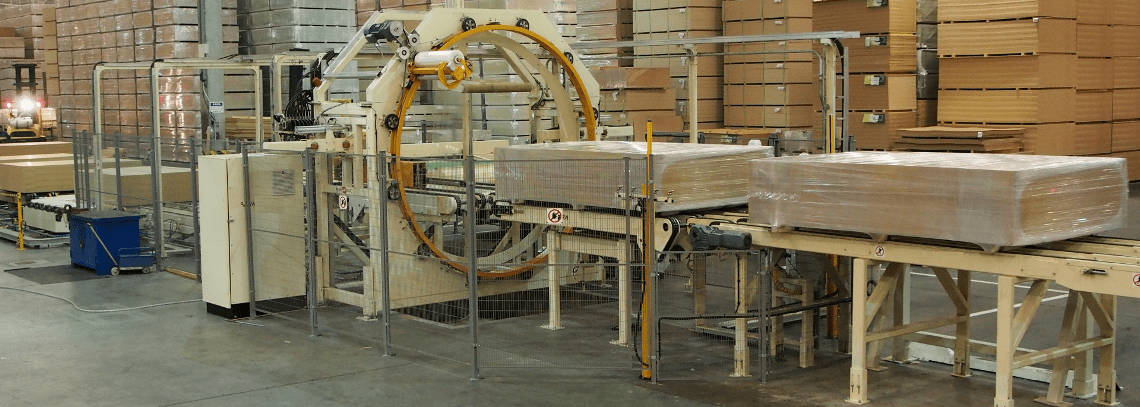

Gypsum Boards Orbital Wrapping Machine

The packaging process is the final touchpoint in ensuring products reach their destination intact, but when it comes to gypsum boards, the stakes are higher. Fragile and bulky, these boards demand specialized handling to prevent damage during transit. Enter the gypsum boards orbital wrapping machine: a technological marvel that has revolutionized how industries package such materials. By wrapping boards seamlessly and securely, this machine not only enhances operational efficiency but also safeguards the product's integrity.

Gypsum boards, widely used in construction, are prone to chipping and cracking if not handled correctly. Traditional methods of securing these boards have proved insufficient in keeping up with modern demands. The orbital wrapping machine steps in as a game-changer, combining precision, speed, and safety to meet these challenges head-on.

Its innovation lies not just in the wrapping mechanism but in how it addresses pain points like waste reduction and manual labor intensity. But how does this machine actually transform the gypsum board packaging landscape? Let’s unwrap the details.

Efficient packaging isn’t just about saving time—it’s about ensuring safety and reducing costs without compromising quality. The gypsum boards orbital wrapping machine exemplifies this balance, offering a sustainable solution for today’s industrial needs.

1. What Makes an Orbital Wrapping Machine Ideal for Gypsum Boards?

1.1 Why precision matters in packaging

In the industrial packaging of gypsum boards, precision is non-negotiable. These materials, while sturdy when installed, are delicate during transit. Even minor errors in handling can lead to significant losses. Orbital wrapping machines are engineered to deliver uniform tension, ensuring that the boards are securely bound without the risk of breakage or shifting.

With consistent pressure applied throughout the wrapping cycle, the risk of over-tightening or loosening is eliminated. The machine’s precision mechanics work seamlessly to wrap every unit as though it were custom-designed, accommodating the specific dimensions and weight of each load.

1.2 How technology reduces packaging waste

Packaging waste is an often-overlooked consequence of inefficient systems. For industries dealing with gypsum boards, excessive use of materials such as film and strapping not only inflates costs but also poses environmental concerns. The orbital wrapping machine optimizes material usage by applying just the right amount of stretch film needed to secure the load.

This reduction in waste directly translates to cost savings, while also allowing businesses to align with sustainability goals. Furthermore, advanced sensors ensure minimal film overlap, a feature that prevents material wastage without compromising the stability of the packaging.

1.3 Addressing unique challenges in gypsum board logistics

Gypsum boards present distinct logistical challenges due to their size, weight, and fragility. Traditional packaging methods often fall short in offering the necessary flexibility to handle such materials. Orbital wrapping machines, however, are designed to adapt.

Their versatility enables them to accommodate varying board dimensions, from standard sizes to custom orders. Moreover, the machine’s rotational wrapping technique ensures that even the edges—often the most vulnerable points—are shielded from impact during transit.

2. How Does Automation Enhance Efficiency in Packaging?

2.1 The role of intelligent controls in reducing errors

Automation introduces a layer of reliability that manual operations simply cannot match. Equipped with intelligent controls, modern orbital wrapping machines can detect irregularities in real-time and adjust operations accordingly. This means fewer errors, less rework, and a smoother packaging workflow overall.

For gypsum boards, where precision and stability are critical, these intelligent systems ensure the wrapping process adheres to stringent quality standards. From monitoring film tension to adapting wrapping speeds, every element is calibrated to perfection.

2.2 Cost savings achieved through automation

Switching to automated orbital wrapping machines is an investment, but one that quickly pays off. By reducing labor costs and minimizing material waste, businesses can significantly lower their operational expenses. Moreover, the machine’s ability to handle large volumes of packaging in a shorter time frame translates to higher productivity and, ultimately, increased profitability.

The automation also brings consistency—each batch of gypsum boards is wrapped identically, ensuring a professional finish that bolsters customer confidence.

2.3 Minimizing downtime with cutting-edge machinery

Unplanned downtime is a costly disruption for any operation. Orbital wrapping machines are designed with durability and ease of maintenance in mind, minimizing such interruptions. Features like automated diagnostics and modular components allow for quick identification and resolution of potential issues, keeping operations running smoothly.

The high-speed functionality of these machines also ensures that large orders can be processed without delays, catering to the demands of fast-paced industrial environments.

3. How Does an Orbital Wrapping Machine Improve Safety Standards?

3.1 Why safety is crucial in gypsum board packaging

Handling gypsum boards involves significant risks, from material damage to worker injuries. Their size and fragility demand specialized equipment that can manage the process safely. Orbital wrapping machines enhance safety by automating critical tasks, reducing the need for manual intervention.

For workers, this means fewer instances of lifting and positioning heavy loads, which are common causes of workplace injuries. For the materials, it ensures secure wrapping without the risks associated with improper handling.

3.2 The impact of design innovations on safety

Modern orbital wrapping machines are built with safety at their core. Features like automatic load sensors, emergency stop buttons, and enclosed wrapping chambers minimize the chances of accidents.

Additionally, ergonomic designs ensure that operators can work comfortably without straining themselves. These innovations collectively create a safer environment, both for workers and the materials being handled.

3.3 Reducing risks with advanced technology

Advanced safety features, such as real-time monitoring systems, further elevate the machine’s capabilities. Sensors can detect irregularities—such as a misaligned load or a film tear—and halt operations instantly to prevent accidents.

This proactive approach to safety ensures that every operation is executed flawlessly, significantly lowering risks and boosting confidence in the packaging process.

4. Why Is Sustainability a Key Benefit of Using Orbital Wrapping Machines?

4.1 How these machines contribute to eco-friendly practices

Sustainability is no longer an optional consideration for businesses; it’s a necessity. Orbital wrapping machines support green initiatives by optimizing material usage and reducing waste. The precision application of stretch film, coupled with minimal overlap, results in significant resource savings.

For companies packaging gypsum boards, this translates to fewer raw materials being consumed, a smaller environmental footprint, and compliance with global sustainability standards.

4.2 Energy efficiency in modern orbital wrapping machines

Beyond material savings, these machines are designed with energy efficiency in mind. Advanced motors and intelligent controls ensure that the equipment uses only as much power as needed, avoiding unnecessary energy consumption.

This efficiency not only reduces operational costs but also aligns businesses with eco-conscious practices, making them more appealing to environmentally aware clients and stakeholders.

4.3 Long-term advantages of sustainable packaging solutions

Investing in sustainable packaging solutions like orbital wrapping machines offers long-term advantages. Reduced waste, lower energy consumption, and minimal environmental impact enhance a company’s reputation and market competitiveness.

Moreover, with increasing regulations around packaging waste, adopting such technology ensures compliance, avoiding potential penalties and reinforcing corporate responsibility.

Conclusion

The gypsum boards orbital wrapping machine is more than just a packaging tool—it’s a cornerstone of modern industrial operations. By combining precision, safety, automation, and sustainability, this technology addresses critical challenges in gypsum board logistics, paving the way for greater efficiency and profitability.

[Claim]: With its innovative design and advanced features, the orbital wrapping machine isn’t merely an option—it’s a necessity for businesses aiming to stay ahead in a competitive landscape.