Automatic Orbital Wrapping Machine

The packaging industry has undergone rapid transformation over the past few decades, and the introduction of automatic orbital wrapping machines has played a significant role in this evolution. As businesses look for ways to improve their packaging processes, reduce waste, and enhance operational efficiency, automatic orbital wrapping machines have emerged as a top choice. These machines provide a seamless solution for wrapping products securely and efficiently, especially for irregularly shaped items. With advancements in technology, these systems offer precise control, enhanced safety features, and significant cost savings in the long run.

Despite their undeniable benefits, many businesses still face challenges when it comes to choosing the right orbital wrapping machine for their operations. From understanding the technical specifications to evaluating the supplier’s post-installation support, the decision-making process can be daunting. As industries continue to prioritize automation and lean operations, the demand for intelligent, automatic wrapping solutions is only expected to grow. This article will delve into the various facets of automatic orbital wrapping machines, examining how they work, the advantages they bring, and what businesses need to consider when investing in these systems.

With the increasing complexity of logistics and the growing demand for sustainable packaging solutions, it’s clear that orbital wrapping machines are an essential part of modern industrial packaging systems. From small-scale manufacturers to large multinational corporations, these machines are proving to be indispensable. But how do you ensure that you are choosing the right machine for your specific needs? Let’s explore the critical considerations.

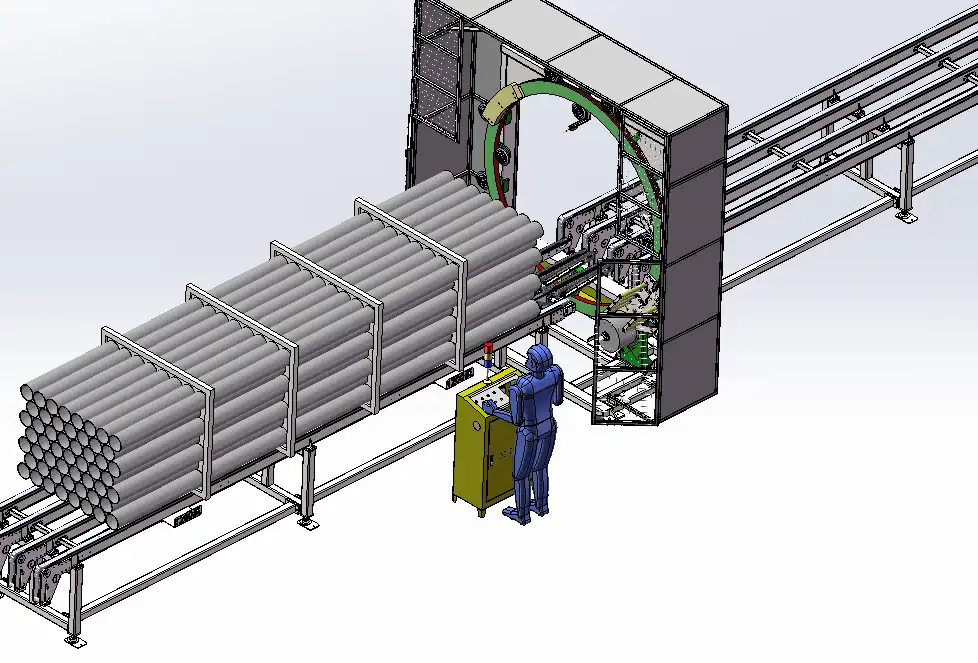

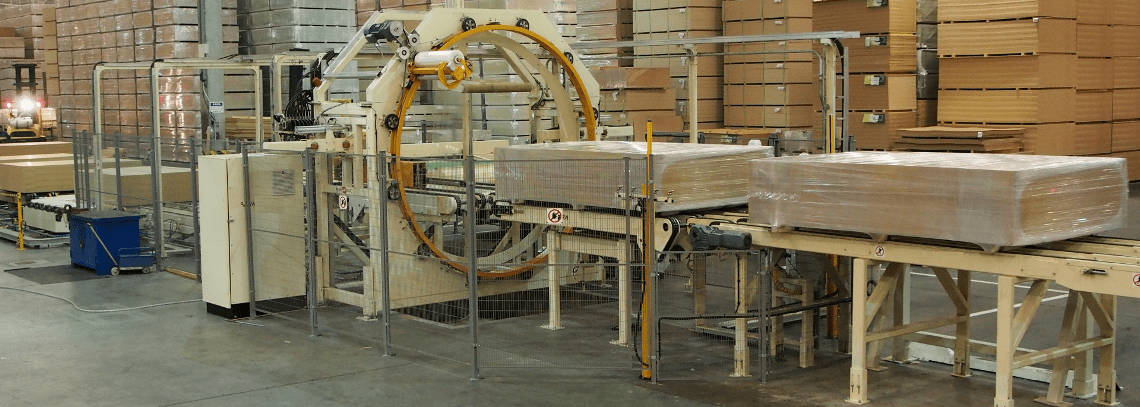

How Does an Automatic Orbital Wrapping Machine Work?

At the heart of an automatic orbital wrapping machine lies a simple yet highly efficient system designed to apply a protective layer of stretch film around the product. The machine operates in a continuous loop, with the film wrapping around the item while the item rotates or moves through the system. The orbital wrapping technique offers several advantages over traditional wrapping methods, particularly when it comes to handling products of various shapes and sizes.

While the machine automatically adjusts its wrapping parameters, the film is applied with consistent tension and precise overlap, ensuring uniform protection. This automated process reduces the risk of human error, enhances product stability, and speeds up the packaging process. Additionally, modern orbital wrapping machines often feature adjustable settings for film tension, rotation speed, and overlap, allowing for customization based on the specific needs of the product being wrapped.

What Are the Key Benefits of Using an Automatic Orbital Wrapping Machine?

Efficiency and Speed

One of the primary advantages of automatic orbital wrapping machines is the increase in operational efficiency. With the ability to wrap products at a much faster rate than manual processes, businesses can streamline their packaging operations and reduce labor costs. This increased speed, coupled with the automation of the wrapping process, leads to significant time savings, especially in high-volume environments.

Consistency and Precision

Automatic orbital wrapping machines provide unparalleled consistency in wrapping. Unlike manual wrapping methods, where human error can result in inconsistent film tension and coverage, orbital wrapping machines ensure that every item receives the same level of protection. This consistency is particularly important for industries where product integrity and packaging quality are crucial.

Cost Savings

Over time, the initial investment in an automatic orbital wrapping machine pays for itself by reducing labor costs and improving material efficiency. The precision of the wrapping process means that less film is wasted, leading to material savings. Additionally, the increased speed of operation allows businesses to handle larger volumes of products with fewer employees, further driving cost savings.

How Do Automatic Orbital Wrapping Machines Improve Sustainability?

In an era where sustainability is at the forefront of industrial operations, automatic orbital wrapping machines play a crucial role in reducing waste and environmental impact. By minimizing film wastage and optimizing the use of stretch film, these machines contribute to more sustainable packaging processes.

Waste Reduction

One of the most significant environmental benefits of using an automatic orbital wrapping machine is the reduction in packaging waste. Traditional wrapping methods often lead to excessive use of materials, particularly when human operators apply inconsistent tension or overlap. In contrast, orbital wrapping machines ensure that the film is used efficiently, minimizing waste and promoting a more sustainable approach to packaging.

Energy Efficiency

Modern orbital wrapping machines are designed with energy efficiency in mind. Many machines come equipped with features that reduce energy consumption while maintaining high levels of performance. This energy efficiency not only lowers operational costs but also reduces the overall environmental footprint of the packaging process.

Recyclable Materials

Many automatic orbital wrapping machines are compatible with recyclable stretch films, which further contribute to sustainable packaging practices. By using recyclable materials, businesses can improve their environmental impact and comply with increasingly strict regulations around packaging waste. This eco-friendly approach is particularly appealing to companies that are looking to improve their sustainability credentials and meet consumer demand for environmentally responsible products.

Why Is Post-Installation Support Crucial for Automatic Orbital Wrapping Machines?

Importance of Reliable Customer Service

When investing in an automatic orbital wrapping machine, it’s important to consider the level of post-installation support provided by the supplier. While the machine itself may be state-of-the-art, ongoing support and maintenance are crucial for ensuring that the equipment continues to perform optimally. A reputable supplier will offer training, troubleshooting, and maintenance services to help businesses maximize their return on investment.

Training and Onboarding

The installation of a new orbital wrapping machine often requires some training for the operators. A good supplier will provide comprehensive training to ensure that employees understand how to use the machine effectively and safely. This training can help minimize the risk of errors, increase operational efficiency, and ensure that the machine is used to its full potential.

Maintenance and Upgrades

Regular maintenance is essential for the longevity of the machine. Suppliers who offer maintenance contracts or on-demand support can help businesses stay ahead of potential issues before they become major problems. Additionally, some suppliers may offer upgrades to keep the machine aligned with evolving technology trends or regulatory standards, further extending the lifespan of the equipment.

How Can You Choose the Right Automatic Orbital Wrapping Machine for Your Business?

When selecting an automatic orbital wrapping machine for your business, several factors need to be taken into account to ensure that the machine will meet your needs and provide the best value over time. These considerations include production volume, the types of products you package, your budget, and the level of automation required. The right machine should align with your business goals, enhance your packaging processes, and fit within your operational constraints.

Production Volume

One of the first things to consider is your production volume. If you operate a high-volume facility, you will need an orbital wrapping machine capable of handling large quantities of products quickly and efficiently. Machines with higher wrapping speeds and the ability to run continuously are ideal for such environments. For smaller businesses or those with more modest packaging needs, a less advanced model may be more suitable, as it will likely come at a lower cost.

Product Size and Shape

Orbital wrapping machines are particularly effective for wrapping irregularly shaped items, as their wrapping method allows the film to be applied evenly across the surface of the product. Before making a purchase, evaluate the types of products you need to wrap. If your products have varying sizes or are oddly shaped, an orbital wrapping machine that can be adjusted to handle these variations will be essential.

Budget Considerations

As with any major investment, your budget will play a crucial role in selecting the right orbital wrapping machine. While high-end models offer advanced features and increased efficiency, they also come with a higher price tag. It’s important to weigh the upfront cost against the long-term savings and efficiency gains the machine can provide. For businesses looking to keep costs down, there are also mid-range models that offer a good balance of performance and price.

How Does Automation Impact the Efficiency of Orbital Wrapping?

Automation is at the core of the orbital wrapping process, and it significantly impacts the efficiency and cost-effectiveness of the machine. By automating the wrapping procedure, businesses can achieve faster wrapping speeds, reduce the likelihood of human error, and maintain consistent packaging quality.

Increased Throughput

One of the biggest advantages of automation is the increase in throughput. Automated systems can wrap products much faster than manual processes, allowing businesses to process more items in less time. This is particularly valuable in high-demand industries where production speed is critical. Furthermore, since the machine operates without the need for constant supervision, it frees up employees to focus on other tasks, thus improving overall operational efficiency.

Consistent Quality and Reduced Errors

Automation ensures that every product is wrapped with the same level of precision, which can be challenging with manual methods. The machine controls the tension of the film, the number of wraps, and the overlap, ensuring that the final package is uniform and secure. This consistency helps prevent issues such as under-wrapping or over-wrapping, which can lead to waste or damaged products.

Labor Reduction

The need for labor-intensive manual wrapping is minimized with automated systems, allowing businesses to operate with fewer employees in the wrapping process. This can result in substantial labor savings, particularly in large-scale operations. Moreover, since the machine operates continuously, downtime between packaging cycles is minimized, further boosting productivity.

How Do Maintenance and Longevity Affect Your Investment in Orbital Wrapping Machines?

When investing in an automatic orbital wrapping machine, the total cost of ownership includes more than just the initial price of the equipment. Ongoing maintenance and the machine’s overall longevity play a major role in determining the long-term value of your investment.

Preventive Maintenance and Cost Savings

Routine maintenance is essential to keeping the orbital wrapping machine running smoothly and preventing costly breakdowns. Preventive maintenance, such as lubricating moving parts, cleaning the machine regularly, and checking for wear and tear, can help extend the machine’s lifespan. By investing in a machine that offers easy-to-perform maintenance tasks and regular servicing from the manufacturer, businesses can avoid costly repairs and minimize downtime.

Longevity and ROI

The longevity of the machine will significantly impact your return on investment. A well-maintained automatic orbital wrapping machine can last for many years, making it a worthwhile long-term investment. To ensure that the machine remains operational for as long as possible, it’s essential to choose a machine made from durable materials and equipped with high-quality components. Furthermore, purchasing a machine with warranties or service agreements can provide peace of mind and protect your investment.

Conclusion

Choosing the right automatic orbital wrapping machine is a crucial decision that can significantly enhance the efficiency, consistency, and sustainability of your packaging process. With careful consideration of factors such as production volume, product size, and budget, businesses can select a machine that aligns with their specific needs. The benefits, from increased speed and precision to cost savings and environmental impact, make automatic orbital wrapping machines a compelling choice for modern packaging operations.

Investing in a high-quality orbital wrapping machine not only improves operational efficiency but also helps businesses stay competitive in a fast-paced industry. By embracing automation, businesses can streamline their processes, reduce waste, and create a more sustainable packaging operation. As technology continues to advance, the capabilities of orbital wrapping machines will only improve, making them an even more valuable asset for industries looking to stay ahead of the curve.