How Pushing Type Online Pallet Changer Enhances High-Speed Pallet Changing

In modern industrial logistics, online pallet changers have revolutionized the way businesses handle palletized goods. As supply chains demand speed, accuracy, and efficiency, traditional methods of manual pallet replacement can no longer meet operational goals. This is where the pushing type online pallet changer steps in, seamlessly integrating into automatic pallet changing lines to offer a faster, safer, and more reliable solution. This article delves into how this advanced automatic pallet changing machine achieves high-speed pallet changes while maintaining operational excellence.

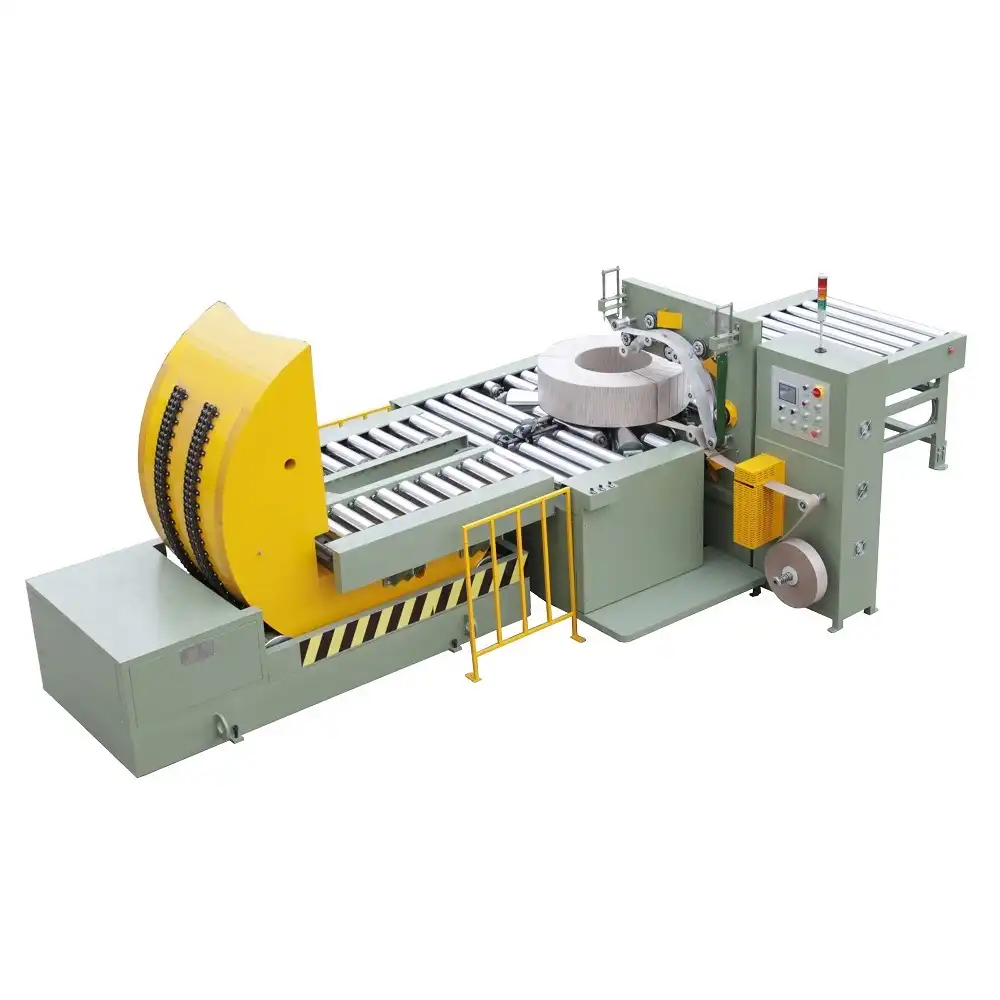

Understanding the Pushing Type Online Pallet Changer

The pushing type online pallet changer is a cutting-edge machine designed for automatic pallet changing in high-speed industrial environments. It works by transferring goods from one pallet to another with a smooth pushing mechanism, minimizing the risk of product damage and ensuring seamless transitions. Unlike traditional pallet changers, this device eliminates the need for lifting or manual adjustments, making it highly efficient and reducing operational downtime.

Key Features of the Pushing Type Pallet Changer

-

High-Speed Operations:

With a capacity to handle up to 55 pallets per hour, the pushing type pallet changer meets the demands of high-speed logistics operations. Its automatic pallet changing line integration ensures uninterrupted workflow, making it ideal for industries like manufacturing, warehousing, and distribution.

-

Precision and Safety:

The device is equipped with sensors to detect pallet alignment and height, ensuring goods are transferred smoothly without dislodging or damage. The pushing mechanism avoids friction between the goods and pallets, safeguarding even fragile items.

-

Robust Construction:

Made of high-quality carbon steel, this automatic pallet changing machine is durable and reliable for long-term use. It can handle a maximum load of 1000 kg, making it suitable for heavy-duty applications.

-

Versatile Compatibility:

Whether using wooden or plastic pallets, the machine adapts to different pallet sizes and types. It supports goods measuring up to 1160 mm × 1180 mm, with a minimum edge extension of 30 mm for optimal stability during transfer.

How the Pushing Type Online Pallet Changer Works

The process of online pallet changing with this machine is streamlined and efficient. Here’s a step-by-step breakdown:

-

Preparation:

Goods are manually separated from their initial pallet, ensuring they meet the size and placement criteria for transfer. Care is taken to avoid stacking pallets unnecessarily, which could disrupt the process.

-

Placement:

The goods are placed on the loading platform, where sensors check their height and alignment. If the height exceeds 2200 mm, the system routes the goods to a higher conveyor section. Otherwise, they proceed directly to the automatic pallet changing machine.

-

Pallet Transfer:

The pushing mechanism smoothly shifts the goods onto the new pallet. The precision-engineered platform avoids friction or misalignment, ensuring the goods remain stable during the transfer.

-

New Pallet Delivery:

An AGV (Automated Guided Vehicle) delivers a new pallet to the machine’s platform. Each delivery includes a single pallet or up to 10 stacked pallets, depending on operational requirements. The AGV aligns the pallet accurately with the machine’s delivery line to maintain efficiency.

-

Completion and Dispatch:

Once the goods are securely transferred, the machine sends them to the designated location using an automatic pallet changing line. Advanced systems such as WCS (Warehouse Control Systems) ensure the goods are sorted and dispatched to the appropriate location without delay.

Scope of Supply:

|

Item

|

Dimensions (L×W×H)

|

Quantity

|

|

Heavy Load Roller Conveyor

|

L1500 × W1200 × H850

|

5

|

|

Dismantling and Stacking Machine

|

L1500 × W2500 × H2800

|

1

|

|

Pallet Dismantling Machine

|

L1500 × W2500 × H2800

|

1

|

|

Pallet Changer

|

L7000 × W1500 × H2800

|

1

|

|

Height Detection Device

|

W1500 × H2500

|

1

|

|

Control System

|

N/A

|

1 Set

|

Advantages of Pushing Type Online Pallet Changer

1. Enhanced Efficiency

Traditional manual methods of pallet changing are labor-intensive and time-consuming. By integrating a pushing type online pallet changer into an automatic pallet changing line, businesses can significantly reduce cycle times. The machine's ability to handle up to 16 meters per minute ensures rapid throughput, meeting the demands of high-volume operations.

2. Improved Safety

Manual pallet changes often expose workers to risks such as heavy lifting injuries and accidents. The automatic pallet changing machine eliminates these hazards by automating the entire process. Its advanced safety mechanisms, including clamps and sensors, ensure secure operations, even with heavy or unstable loads.

3. Cost Savings

Automating the pallet-changing process reduces labor costs and minimizes material waste. The machine’s precise handling prevents damage to goods, ensuring they arrive at their destination intact. This reliability lowers the risk of product loss, contributing to long-term cost savings.

4. Seamless Integration

The pushing type online pallet changer is designed to integrate effortlessly with existing systems. Whether paired with AGVs, conveyors, or WCS, it operates as part of a cohesive automatic pallet changing line. This flexibility allows manufacturers to upgrade their logistics systems without overhauling existing infrastructure.

Selecting the Right Automatic Pallet Changing Machine Manufacturer

When investing in an online pallet changer, choosing the right manufacturer is critical. Look for a provider with expertise in designing high-speed, reliable, and durable machines. Key factors to consider include:

-

Customizability: Ensure the machine can adapt to your specific operational needs, such as pallet size and load capacity.

-

Support and Maintenance: Opt for a manufacturer that offers comprehensive after-sales support, including training, spare parts, and maintenance services.

-

Technology: Choose a provider that incorporates advanced features like IoT-enabled monitoring, automated sensors, and PLC (Programmable Logic Controller) systems.

A reputable automatic pallet changing machine manufacturer not only provides high-quality equipment but also partners with you to optimize your operations and ensure long-term success.

Conclusion

The pushing type online pallet changer represents a significant leap forward in logistics and material handling. By automating and streamlining the pallet-changing process, it enhances efficiency, improves safety, and reduces costs. Integrated into an automatic pallet changing line, this machine ensures high-speed operations that meet the demands of modern supply chains.

For businesses seeking to upgrade their logistics capabilities, partnering with a trusted automatic pallet changing machine manufacturer is the key to unlocking greater productivity and operational excellence. Whether in manufacturing, warehousing, or distribution, the online pallet changer is an indispensable tool for staying competitive in today’s fast-paced industrial landscape.