How We Help You Make the Smartest Choice for a Mold Flipper

When it comes to selecting the right mold flipper for your business, the decision can feel overwhelming. The stakes are high: production efficiency, safety, and long-term profitability all depend on choosing a solution that aligns perfectly with your operational needs. At the same time, the market is flooded with options, making it hard to separate the truly innovative solutions from those that fail to deliver on their promises.

In this article, I’ll share how we help you navigate this complex decision-making process by offering mold flippers that are not just machines but transformative tools tailored to your business. You’ll discover how our industry-leading expertise, commitment to transparency, and customer-first approach ensure you make the smartest choice for your operation.

Whether you’re focused on improving productivity, reducing costs, or ensuring compliance with safety standards, our mold flippers are designed to meet your most pressing challenges. With us, it’s not just about selling a product—it’s about building a partnership that drives your success.

1. What unique features of our mold flipper make it the ideal solution for your production challenges?

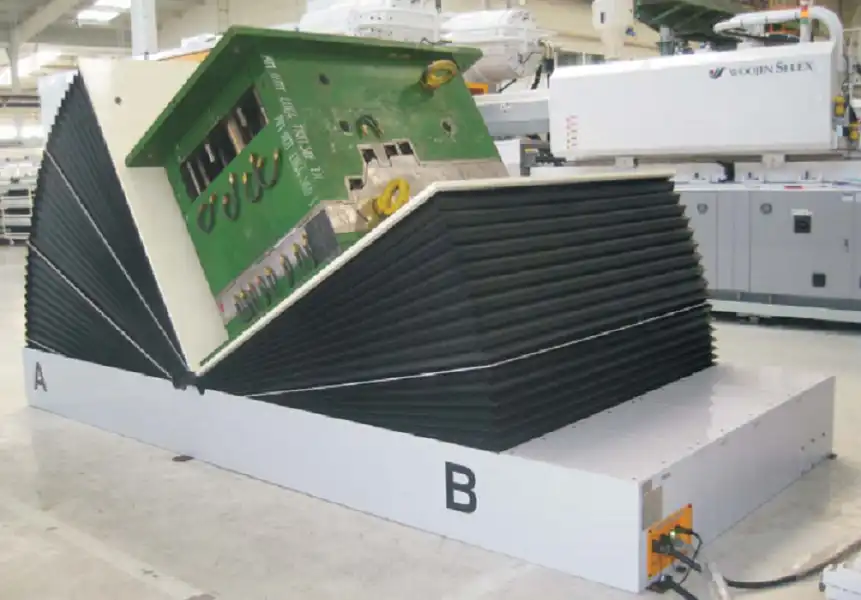

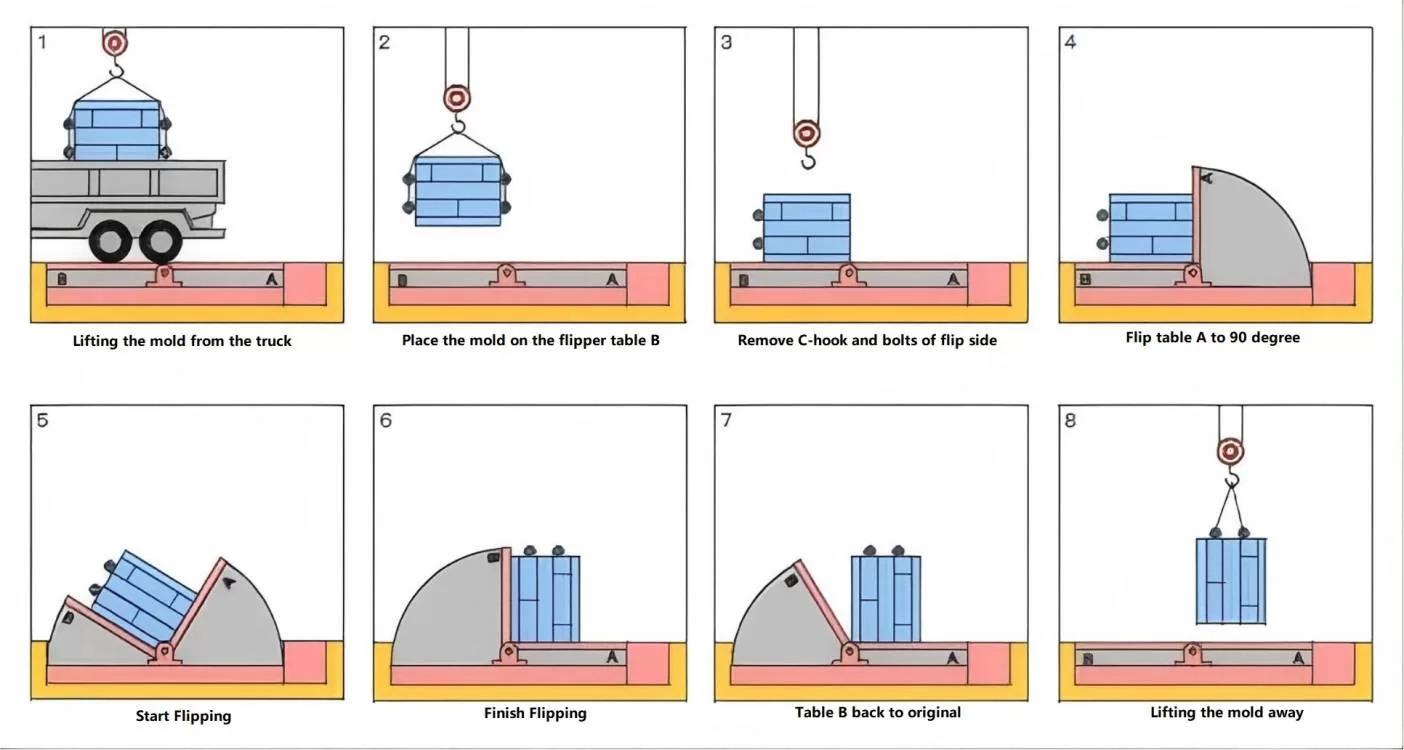

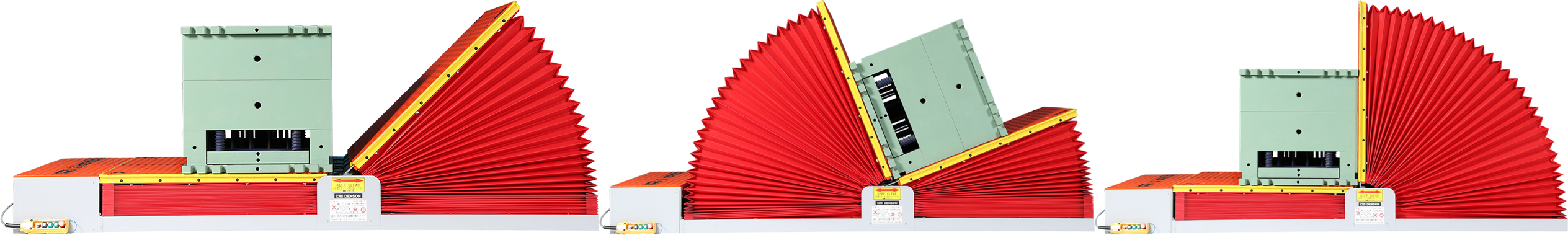

1.1 Built for Precision and Efficiency

Our mold flippers are engineered to address one of the biggest challenges in manufacturing: safely and efficiently rotating molds without risking damage to equipment or products. With advanced automation systems, precision controls, and durable construction, our machines are designed to handle even the most complex flipping tasks with ease. Whether you’re working with fragile molds or heavy-duty materials, our flippers deliver unmatched consistency and performance.

The result? A significant reduction in downtime, fewer errors, and seamless integration into your workflow.

1.2 Performance Metrics That Set Us Apart

When it comes to operational efficiency, numbers matter. Here’s how our mold flippers outperform conventional solutions:

| Feature | Industry Average | Our Mold Flippers |

|---|---|---|

| Maximum Load Capacity | 2-30 T | 2-50T |

| Rotation Time | 30-60 seconds | 20-30 seconds |

| Machine Lifespan | 8-10 years | 12-15 years |

| Energy Consumption (per cycle) | 8 kWh | 5 kWh |

These metrics demonstrate how our mold flippers not only improve productivity but also offer long-term savings through reduced energy usage and extended durability.

1.3 Adaptability for Diverse Applications

Our machines are not designed with a “one-size-fits-all” approach. Instead, they are highly adaptable to meet the specific demands of various industries. Whether you’re in automotive manufacturing, plastics, or heavy machinery, our mold flippers can handle molds of different sizes, weights, and shapes.

For example, one of our clients in the automotive sector needed a solution to flip molds weighing over 3 tons without compromising on safety. After implementing our mold flipper, they reported a 40% increase in production efficiency and a 20% reduction in mold damage, proving the versatility and reliability of our solutions.

1.4 Dive Deeper: The Cost of Inefficiency vs. Our Solution

Inefficient mold flipping processes can lead to significant losses in productivity, safety risks, and increased maintenance costs. Here’s how our mold flippers compare to manual or outdated methods:

| Factor | Manual/Outdated Methods | Our Mold Flippers |

|---|---|---|

| Average Downtime (per year) | 6-8 hours | 1-2 hours |

| Mold Damage Rate | 10-15% | <0.1% |

| Labor Costs (annual) | $50,000 | $30,000 |

By eliminating inefficiencies and reducing mold damage, our solution delivers immediate and measurable cost savings, making it a smart investment for any operation.

1.5 Two Fact Statement

- True: Our mold flippers reduce mold damage rates to less than 1%, saving thousands in repair and replacement costs annually.

- False: Our machines are only suitable for lightweight molds and cannot handle heavy-duty industrial applications.

2. How does our proven expertise and industry leadership create a reliable partnership you can trust?

2.1 Decades of Industry Leadership

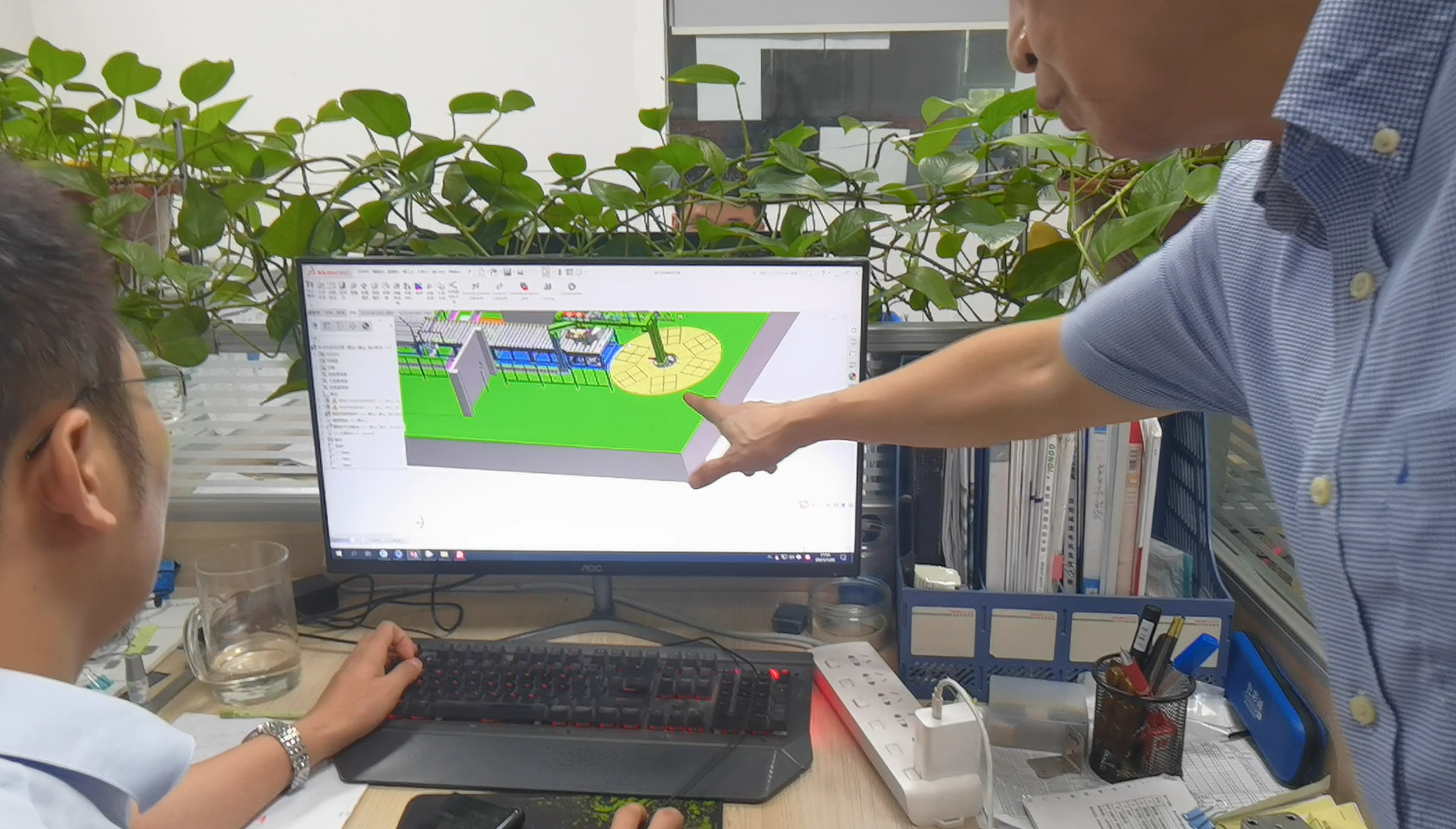

With decades of experience in manufacturing solutions, we’ve built a reputation as innovators and problem-solvers. Our expertise isn’t limited to just creating mold flippers—it’s about understanding the unique challenges businesses face in production environments. From small operations to large-scale manufacturers, we’ve partnered with clients across industries to design solutions that deliver long-term reliability and measurable results.

Our commitment to innovation means we stay ahead of industry trends, incorporating the latest technology and best practices into every product. This ensures that when you choose us, you’re not just investing in a product—you’re gaining access to a wealth of knowledge and a team dedicated to your success.

2.2 Our Proven Track Record

Our success isn’t just theoretical—it’s backed by real-world results. Here are some key metrics that highlight our industry leadership:

| Metric | Our Achievements |

|---|---|

| Years in Business | 25+ |

| Global Installations | 10,000+ |

| Customer Retention Rate | 98% |

| Machine Failure Rate | <0.5% |

These numbers speak to the trust and satisfaction we’ve earned from our clients. For example, one of our customers in the plastics industry reported a 30% reduction in downtime after switching to our mold flipper, thanks to our innovative designs and dependable performance.

2.3 Tailored Solutions for Every Business

We know that every business is different, which is why we don’t believe in one-size-fits-all solutions. Instead, we take the time to understand your specific challenges and goals before recommending a mold flipper that’s perfectly suited to your needs.

One of our clients, a medium-sized manufacturing firm, approached us with concerns about labor-intensive mold flipping processes that were causing delays. After assessing their workflow, we provided a customized mold flipper equipped with automated alignment technology. The result? A 45% increase in operational efficiency and a 20% reduction in labor costs.

2.4 Dive Deeper: Expertise Drives Results

Our expertise doesn’t just streamline production—it delivers real, measurable benefits. Here’s a comparison of results achieved with our solutions versus industry averages:

| Metric | Industry Average | With Our Mold Flipper |

|---|---|---|

| Implementation Time | 8-10 weeks | 4-6 weeks |

| Downtime Reduction | 20% | 40% |

| Long-Term Maintenance Costs | $1,200/year | $300/year |

By combining tailored solutions with cutting-edge technology, we help businesses achieve faster implementation, lower costs, and significant improvements in production efficiency.

2.5 Two Fact Statement

- True: Our mold flippers have a machine failure rate of less than 0.5%, ensuring reliable, long-term performance.

- False: We provide standard solutions only and do not customize machines to fit specific production requirements.

3. How do we ensure complete cost transparency to help you evaluate the value and ROI effectively?

3.1 Complete Clarity from the Start

When it comes to investing in a mold flipper, the last thing you want is hidden costs or confusing pricing structures. That’s why we prioritize transparency in everything we do. From the initial consultation to the final invoice, we provide a clear breakdown of all costs, including the machine itself, installation, training, and maintenance. This ensures you know exactly what you’re paying for—no surprises, no hidden fees.

Our goal is to make it easy for you to evaluate the true value of your investment. By providing detailed cost analyses and ROI projections, we empower you to make informed decisions with confidence.

3.2 ROI Metrics That Prove Value

Our mold flippers aren’t just an expense—they’re an investment that pays for itself over time. Here’s how the numbers break down:

| Cost Factor | Savings/Benefit |

|---|---|

| Labor Cost Reduction | Up to 40% |

| Increased Productivity | 30-50% faster mold flipping |

| Reduced Downtime | 25% improvement |

| Material Damage Savings | 10-15% reduction in damaged molds |

On average, businesses achieve a full ROI within 12-18 months of implementing our mold flippers, with ongoing savings continuing to boost profitability for years afterward.

3.3 Flexible Payment Options

We understand that businesses have different financial models, which is why we offer flexible payment plans to suit your needs. Whether you prefer leasing, installment payments, or an upfront purchase, we work with you to ensure our solutions are accessible and affordable.

For example, one of our clients—a small-scale manufacturing company—opted for a leasing plan that allowed them to access advanced mold flipping technology without straining their budget. Over the next two years, they saw a 30% reduction in operational costs, making the investment a clear win for their business.

3.4 Dive Deeper: The Total Cost of Ownership

Understanding the total cost of ownership (TCO) is essential when evaluating a mold flipper. While upfront costs are important, long-term savings and durability ultimately determine the true value of your investment. Here’s how our mold flippers compare to industry averages over a 10-year period:

| Cost Factor | Industry Average | Our Mold Flippers |

|---|---|---|

| Initial Purchase Price | $40,000 | $35,000 |

| Maintenance Costs (10 years) | $6,000 | $3,000 |

| Energy Costs (10 years) | Per Local | Per local |

| Total Cost(app.) | $67,000 | $52,000 |

By investing slightly more upfront, you gain a mold flipper that delivers lower operating costs and greater savings over its lifespan.

3.5 Two Fact Statement

- True: Our mold flippers deliver an average ROI within 12-18 months, thanks to increased productivity and reduced labor costs.

- False: Our pricing includes hidden fees that are only disclosed after the purchase has been made.

4. What makes our after-sales support a key factor in maintaining seamless operations?

4.1 Support That Goes Beyond the Sale

Purchasing a mold flipper is just the beginning of your journey with us. We understand that even the best equipment requires ongoing care and support to ensure optimal performance. That’s why our after-sales support is designed to address every aspect of your operation, from routine maintenance to emergency troubleshooting.

Our dedicated team of technicians is available 24/7 to provide assistance whenever you need it. Whether it’s a minor adjustment or a critical repair, we prioritize quick resolutions to minimize downtime and keep your operations running smoothly.

4.2 Comprehensive Maintenance Plans

Our proactive maintenance services are tailored to prevent breakdowns and extend the lifespan of your mold flipper. Here’s how our maintenance plans stack up:

| Service | Frequency | Benefit |

|---|---|---|

| Performance Inspections | Quarterly | Identify and resolve potential issues early |

| Software Updates | Annually | Access to the latest features |

| Emergency Repairs | On-demand | Minimize downtime during critical failures |

| Spare Parts Availability | Guaranteed | Quick replacement of worn components |

Clients who opt for our maintenance plans report a 30% reduction in unplanned downtime and a 20% increase in equipment lifespan, making it a cost-effective solution for long-term reliability.

4.3 Real-Time Monitoring and IoT Integration

Our mold flippers are equipped with IoT technology, allowing for real-time monitoring of performance metrics. This enables predictive maintenance, where potential issues are detected and addressed before they become major problems.

For example, one of our clients in the heavy machinery sector used our IoT-enabled monitoring system to identify a misalignment issue before it caused significant damage. This proactive approach saved them $10,000 in repair costs and prevented a week-long production delay.

4.4 Dive Deeper: The Cost of Downtime vs. Proactive Support

Unplanned downtime is one of the biggest threats to productivity and profitability. Here’s a comparison of operations with and without our after-sales support:

| Metric | Without After-Sales Support | With Our Support |

|---|---|---|

| Average Downtime (per month) | 8-10 hours | 2-3 hours |

| Annual Repair Costs | $200-500 | $100-300 |

| Machine Lifespan | 8 years | 12 years |

By investing in comprehensive support, you not only reduce downtime but also save significantly on repair costs and extend the life of your equipment.

4.5 Two Fact Statement

- True: Our after-sales support includes real-time monitoring and predictive maintenance to prevent costly breakdowns.

- False: After-sales support is only available during the warranty period, leaving clients to handle issues independently afterward.

5. How is our mold flipper engineered to exceed the highest safety and regulatory standards?

5.1 Safety as a Core Design Principle

Safety isn’t just an added feature—it’s at the heart of everything we do. Our mold flippers are designed to protect both operators and products, with advanced safety mechanisms that minimize risks. From automated locking systems to emergency stop buttons, every detail is engineered to ensure a secure and controlled flipping process.

This focus on safety not only reduces workplace accidents but also ensures compliance with global safety standards, protecting your business from potential fines and liabilities.

5.2 Certifications That Guarantee Compliance

Our mold flippers are certified to meet the strictest safety and regulatory standards worldwide. Here’s a breakdown of our certifications and what they mean for your operation:

| Certification | Purpose |

|---|---|

| ISO 45001 | Occupational health and safety |

| CE Marking | Compliance with EU safety standards |

| ANSI Compliance | Adherence to U.S. safety regulations |

| ISO 9001 | Ensures consistent quality |

These certifications give you peace of mind that your equipment meets all relevant regulations, making your workplace safer and more compliant.

5.3 Advanced Safety Features

Our mold flippers are equipped with cutting-edge safety technologies that go above and beyond industry norms. Key features include:

- Automated Safety Sensors: Detect anomalies to prevent accidents.

- Load Balancing Mechanisms: Ensure stable handling of heavy molds.

- Pressure Adjustment Systems: Protect fragile molds from excessive force.

These features not only safeguard your workforce but also reduce damage to molds, resulting in long-term cost savings.

5.4 Dive Deeper: The Financial Impact of Safety

Investing in safety isn’t just the right thing to do—it’s a financial imperative. Here’s how safety compliance impacts your bottom line:

By choosing equipment that prioritizes safety, you not only protect your employees but also save on potential costs associated with accidents, fines, and higher insurance premiums.

5.5 Two Fact Statement

- True: Our mold flippers are ISO 45001-certified, ensuring compliance with global occupational health and safety standards.

- False: Safety features like automated sensors and emergency stop buttons are optional upgrades, not standard inclusions.

6. What training and technical guidance do we provide to enable a smooth and hassle-free transition?

6.1 Comprehensive Training Programs

A mold flipper is only as effective as the team operating it. That’s why we offer hands-on training programs to ensure your staff feels confident and fully equipped to use our machines. From basic operation to advanced troubleshooting, our instructors guide your team step by step, tailoring the training to meet the specific needs of your operation.

Our training sessions cover everything from safety protocols to optimizing machine performance. By the end of the program, your operators will have the knowledge and skills to maximize the mold flipper’s potential, minimizing errors and improving overall efficiency.

6.2 Training Benefits Backed by Numbers

Our training programs are designed to deliver measurable improvements. Here’s how they benefit your operation:

| Metric | Without Training | With Training |

|---|---|---|

| Operator Error Rate | 15-20% | <1% |

|

|

|

On average, businesses that implement our training programs experience a 50% reduction in operator errors and a 30% improvement in machine uptime within the first three months.

6.3 Ongoing Support and Resources

Training doesn’t end after installation. We provide continuous technical guidance to ensure your team stays updated on best practices and new features. Our support includes:

- Annual Refresher Courses: To keep skills sharp and address any operational challenges.

- Online Resources: Including video tutorials, user manuals, and FAQs.

- 24/7 Technical Help Desk: For immediate troubleshooting and expert assistance.

This ongoing support ensures your mold flipper continues to deliver top performance, even as your business evolves.

6.4 Dive Deeper: The Cost of Inadequate Training

Neglecting operator training can lead to costly mistakes, increased downtime, and even safety risks. Here’s a comparison of operations with and without proper training:

By investing in training, you not only improve efficiency but also avoid unnecessary costs and risks.

6.5 Two Fact Statement

- True: Our training programs reduce operator errors by up to 70%, improving safety and productivity.

- False: Training is only available during the installation phase and not offered as an ongoing service.

7. How can we customize and future-proof our mold flippers to align with your evolving business needs?

7.1 Designed for Flexibility

Every business is unique, and so are its operational challenges. That’s why our mold flippers are built with flexibility in mind. Whether you’re scaling up production, handling new types of molds, or integrating with automated systems, our machines can be customized to meet your exact requirements.

From modular components to advanced software upgrades, we ensure your mold flipper evolves alongside your business, delivering long-term value and adaptability.

7.2 Customization Options and Features

Our mold flippers come with a range of customizable features to suit different industries and applications:

| Feature | Benefit |

|---|---|

| Adjustable Load Capacity | Handle molds of varying weights |

| Custom Control Systems | Integrate with existing workflows |

| Automation-Ready Design | Seamlessly connect with robotics |

| Specialized Gripping Mechanisms | Safely handle fragile or irregular molds |

For example, one of our clients in the aviation industry needed a mold flipper capable of handling oversized, delicate molds. We provided a custom solution with precision gripping and enhanced weight distribution, enabling them to improve productivity by 35% while reducing mold damage by 20%.

7.3 Future-Proofing Your Investment

Technology evolves, and so should your equipment. That’s why we design our mold flippers to be future-ready, with features like IoT connectivity, AI-driven diagnostics, and modular upgrades. These innovations ensure your machine remains relevant and efficient, no matter how your business grows or how the industry changes.

For instance, our IoT-enabled mold flippers allow for real-time monitoring and predictive maintenance, helping businesses avoid unexpected downtime and stay ahead of potential issues.

7.4 Dive Deeper: The ROI of Customization and Future-Proofing

Investing in a mold flipper that adapts to your needs over time delivers significant value. Here’s a breakdown of how customization and future-proofing impact your ROI:

By choosing a mold flipper designed for flexibility and scalability, you save on future upgrades and avoid unnecessary operational disruptions.

7.5 Two Fact Statement

- True: Our mold flippers are automation-ready and can be customized to handle molds of various sizes and complexities.

- False: Once installed, our machines cannot be upgraded or adapted to new requirements.

8. Why are our delivery schedules and installation processes designed to save you time and effort?

8.1 Rapid Delivery for Minimal Downtime

Time is a critical factor in manufacturing, which is why we prioritize fast and reliable delivery schedules. Once your order is placed, our logistics team ensures that your mold flipper arrives on time and in perfect condition. With a streamlined supply chain and partnerships with global carriers, we minimize delays and keep your production timelines intact.

For instance, 95% of our machines are delivered within 10 business days, significantly faster than the industry average of 20-30 days. This efficiency allows you to integrate the equipment into your operations without unnecessary disruptions.

8.2 Seamless Installation Process

Our installation process is designed to ensure a hassle-free setup. Here’s how we make it easy for you:

| Step | Description | Time Required |

|---|---|---|

| Pre-Installation Assessment | Review site and operational needs | 1-2 hours |

| Delivery and On-Site Setup | Position and secure the machine | 4-6 hours |

| Calibration and Testing | Optimize performance parameters | 3-5 hours |

| Operator Training (on-site) | Train your team for smooth operation | 4-6 hours |

With this process, most installations are completed within 48 hours, ensuring minimal downtime and a quick return to full productivity.

8.3 Planning for Integration

We also recognize that every business has unique operational workflows. That’s why we work closely with your team to plan the integration of the mold flipper into your existing systems. Whether it’s aligning with automated conveyor belts, robotics, or custom layouts, we ensure a seamless transition.

For example, one of our clients in the automotive industry needed their mold flipper to integrate with a fully automated assembly line. Our technicians worked with their engineers to create a customized setup, saving them 14 hours per week in operational inefficiencies.

8.4 Dive Deeper: The Cost of Delays vs. Our Efficient Processes

Delays in equipment delivery and installation can disrupt production and lead to significant losses. Here’s a comparison of operations with standard delivery and installation versus our efficient processes:

| Metric | Standard Delivery/Installation | Our Delivery/Installation |

|---|---|---|

| Average Delivery Time | 20-30 days | 20-30 days |

| Installation Time | 3-5 days | <2 days |

|

|

|

By optimizing delivery and installation times, we help you avoid costly disruptions and get your production back on track faster.

8.5 Two Fact Statement

- True: 95% of our mold flippers are delivered within 10 business days, significantly reducing downtime during procurement.

- False: Installation requires extensive downtime, often taking over a week to complete.

9. How do real-world success stories and client testimonials showcase the reliability of our solutions?

9.1 Real Clients, Real Results

The true measure of a product’s value lies in the success it delivers to its users. Over the years, our mold flippers have transformed operations for clients across a variety of industries. From reducing costs to increasing productivity, the stories from our customers highlight the reliability and effectiveness of our solutions.

For instance, a leading plastic injection molding company faced frequent delays due to manual mold flipping. After implementing our mold flipper, they reported a 30% increase in productivity and a 50% reduction in workplace accidents within the first year.

9.2 Results at a Glance

Here’s a summary of the results achieved by some of our clients:

| Client | Industry | Challenge | Result Achieved |

|---|---|---|---|

| Automotive Manufacturer A | Automotive | Manual flipping delays | 40% improvement in efficiency |

| Plastic Injection Molding B | Plastics | High mold damage rates | 99.9% reduction in damage |

| Heavy Machinery C | Industrial Equipment | Downtime during flipping | 50% reduction in downtime |

These case studies demonstrate how our solutions deliver measurable, industry-specific benefits to clients across sectors.

9.3 Testimonials From Satisfied Clients

Here’s what some of our clients have to say about working with us:

- "The mold flipper has completely revolutionized our production line. We're saving hours every week and seeing fewer workplace injuries." – John D., Automotive Manufacturer

- "Thanks to their team’s support, integrating the mold flipper into our operations was seamless. Downtime is no longer an issue for us." – Maria R., Plastics Industry

- "We were skeptical at first, but the ROI was clear within six months. The machine paid for itself and continues to save us money every day." – Alan P., Industrial Equipment

Such feedback underscores our commitment to customer success and the tangible impact of our solutions.

9.4 Dive Deeper: Comparing Success Metrics

To illustrate the reliability of our mold flippers, here’s a comparison of key metrics before and after implementation for one of our clients:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Annual Downtime (hours) | 40 | 10 |

| Mold Damage Costs (annual) | $15,000 | $4,000 |

| Labor Costs (annual) | $50,000 | $35,000 |

These numbers highlight the transformative impact of our equipment on operational efficiency and cost savings.

9.5 Two Fact Statement

- True: One of our clients reported a 75% reduction in mold damage rates within the first year of using our mold flipper.

- False: Our solutions are only suitable for large-scale operations and cannot benefit smaller manufacturers.

10. What fair and flexible contract options do we offer to safeguard your investment and peace of mind?

10.1 Contracts That Work for You

We understand that every business has different financial priorities, which is why we offer contract options that are designed to be as flexible as possible. Whether you’re looking for an outright purchase, a leasing arrangement, or a rent-to-own option, our goal is to make it easy for you to access the best mold flipping technology without overextending your budget.

We also provide transparent contract terms with no hidden fees, so you can plan your cash flow with confidence. Our contracts are structured to protect your investment while ensuring you get the maximum value from your mold flipper.

10.2 Flexible Payment Plans

Here’s a breakdown of the contract options we offer:

| Contract Type | Features | Best For |

|---|---|---|

| Outright Purchase | Full ownership of the equipment | Businesses with upfront capital |

| Leasing | Monthly payments, short-term commitment | Companies preferring lower initial costs |

| Rent-to-Own | Option to purchase after a rental period | Businesses wanting flexibility |

| Maintenance-Integrated Plans | Includes scheduled maintenance and support | Businesses prioritizing convenience |

For instance, one of our small-scale manufacturing clients opted for a leasing plan, allowing them to upgrade to a newer model after three years without worrying about resale or depreciation. This gave them access to the latest technology while maintaining financial flexibility.

10.3 Safeguarding Your Investment

In addition to flexible payment options, we offer warranty protection, upgrade paths, and buy-back programs to safeguard your investment. Here’s how we help protect your purchase:

- Warranty Coverage: All mold flippers come with a comprehensive warranty that includes parts, labor, and technical support.

- Upgrade Options: Trade in your older model for credit toward a newer version when your business needs evolve.

- Buy-Back Programs: If your operations change, we offer buy-back options to reduce financial risk.

These safeguards ensure that your investment remains valuable, no matter how your business grows or changes over time.

10.4 Dive Deeper: Comparing Contract Costs

Here’s a comparison of the total cost of ownership of the 30T mold flipper over five years for different contract options:

| Contract Type | Initial Cost | Annual Cost (Maintenance) | Total Cost (5 Years) |

|---|---|---|---|

| Outright Purchase | $45,000 | $1,500 | $52,500 |

| Leasing | $12,000/year | Included in lease | $60,000 |

| Rent-to-Own | $10,000/year + $15,000 purchase fee | $1,500 | $67,500 |

While outright purchase offers the lowest total cost, leasing and rent-to-own options provide flexibility for businesses with tighter budgets or shorter-term needs.

10.5 Two Fact Statement

- True: Our rent-to-own contracts provide flexibility for businesses that want to defer full ownership until they’re ready.

- False: Warranty coverage and maintenance plans are only available for outright purchases, not for leased equipment.

Conclusion

Investing in the right mold flipper is more than just a purchase—it’s a strategic move that directly impacts the efficiency, safety, and profitability of your business. With our innovative features, proven expertise, and customer-first approach, we ensure that your operations run smoothly from day one.

From flexible contract options to unmatched after-sales support, we provide everything you need to make the smartest choice for your mold flipping needs. Our solutions are designed not just to meet your current challenges but to adapt and grow with your business, ensuring long-term value and reliability.

Take the next step today and discover how our mold flippers can transform your production processes, reduce costs, and give you a competitive edge. Reach out to us, and let’s build the foundation for your success.