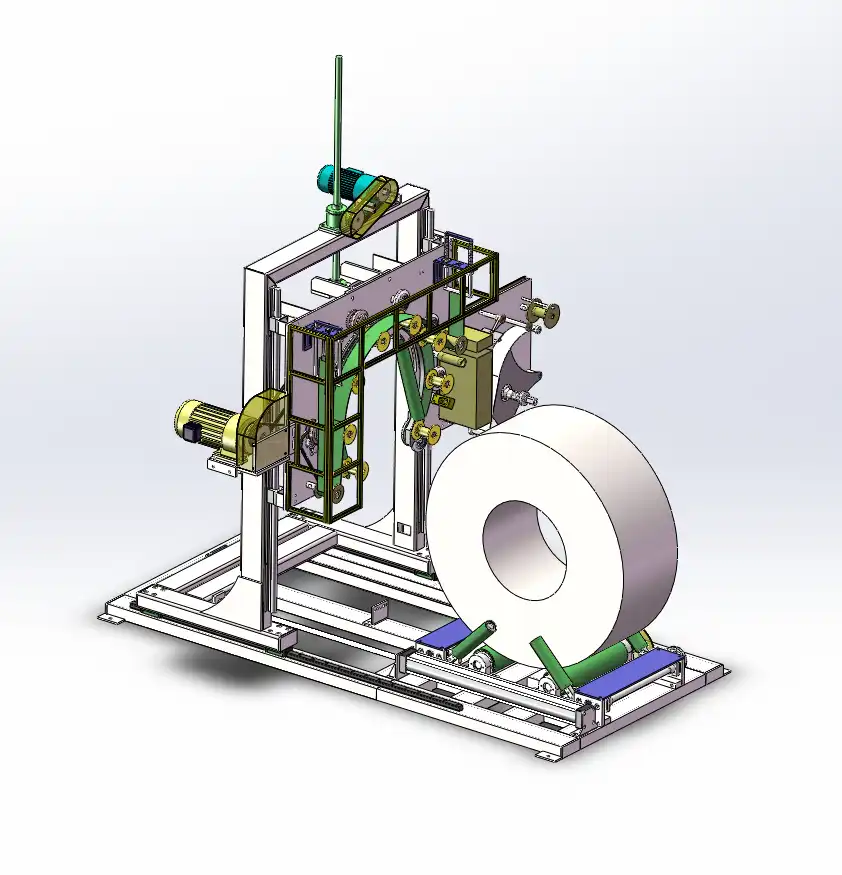

Subject: Rotating Coil

DELIVERABLES:

Rotating Coil 72” (1830mm)

The stand will be designed to accommodate the following coils:

· Coil Diameter: 60” to 84” (1530-2140mm)

· Width: Up to 72”

· Strip Thickness: Up to 0.750”(0.19mm)

· Weight: Up to 72,000 pounds (32700kg)

· The powered rubber coated rollers will turn the outside of the roll at approximately 18 FPM

· which equates to nearly 1 RPM on the coil, depending on coil diameter. (18fpm=5.5m/min,1fpm=0.3m/min)

·

· The frame and chain guard will be powder coated standard QM colors.

· The stand will include the following features:

· Designed for a center of the coil working height of around 48”. - A 4” wide notched area or

· bearings in the middle of the roll placement area for the banding to pass through for being

· put on / cut off. (48”=1220mm, 4”=102mm)

· Lift point in the frame for lifting the equipment in an unloaded condition. –

· A plate over the motor to protect it from impact with the product. –

· Motor power will be 240/480 VAC 3 Phase.

· A remote control tethered pendent with continuous / stop / jog switch, Estop button, and

· forward / stop / reverse switch.

· Motor control including contactors, overloads, and safety circuit will be located in

· a control box on the side of the equipment.

· Document Package that will include Electrical Schematic, Manual of Operation

· Documentation and Technical Support

Rotating Coil 96” (2440mm)

The stand will be designed to accommodate the following coils:

· Coil Diameter: 60” to 84” (1530-2140mm)

· Width: Up to 96”

· Strip Thickness: Up to 0.750” (0.19mm)

· Weight: Up to 82,000 pounds (37200kg)

· The powered rubber coated rollers will turn the outside of the roll at approximately 18 FPM

o which equates to nearly 1 RPM on the coil, depending on coil diameter.

· The frame and chain guard will be powder coated standard QM colors.

· The stand will include the following features:

· Designed for a center of the coil working height of around 48”. - A 4” wide notched area or

o bearings in the middle of the roll placement area for the banding to pass through for being

o put on / cut off.

· Lift point in the frame for lifting the equipment in an unloaded condition. –

· A plate over the motor to protect it from impact with the product. –

· Motor power will be 240/480 VAC 3 Phase.

· A remote control tethered pendent with continuous / stop / jog switch, Estop button, and

o forward / stop / reverse switch.

· Motor control including contactors, overloads, and safety circuit will be located in

o a control box on the side of the equipment.

· Document Package that will include Electrical Schematic, Manual of Operation

· Documentation and Technical Support

More coil packing machine: https://www.fhopepack.com/Coil_packing_machine.html

Automatic steel coil packagign line: coil packing line