Market Analysis: Finding the Best Orbital Packaging Machine for Your Application

In the fast-paced world of manufacturing and logistics, orbital packaging machines have become essential tools for efficiently wrapping long, bulky, or irregularly shaped products. These machines are designed to improve product protection, reduce packaging time, and lower operational costs. With various models and features available in the market, finding the best orbital packaging machine for your application requires a thorough understanding of your specific needs and the latest market trends. This article provides a comprehensive market analysis to help you choose the best orbital packaging machine tailored to your operational requirements.

1. Understanding the Purpose of an Orbital Packaging Machine

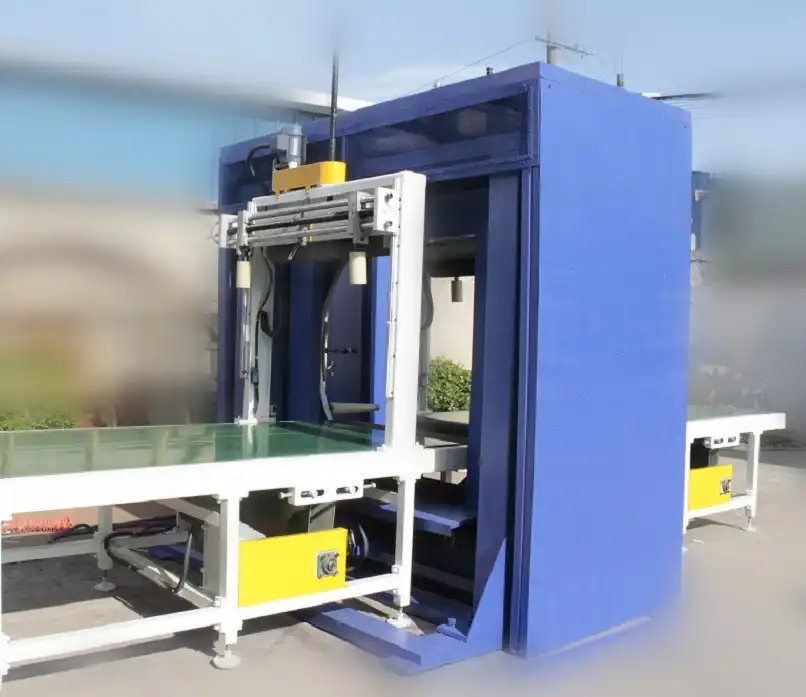

An orbital packaging machine works by wrapping products in a horizontal orientation using stretch film or other materials. These machines are ideal for packaging long or bulky items that cannot easily be wrapped with traditional vertical wrapping systems. Industries that commonly use orbital packaging machines include construction materials, aluminum profile production, furniture, and logistics companies handling long goods like pipes or metal rods.

The primary purpose of these machines is to protect products during storage and transportation by applying a tight and secure wrap. The stretch film or protective material provides a barrier against moisture, dust, and physical damage, ensuring that the products reach their destination in optimal condition.

2. Key Features to Look for in an Orbital Packaging Machine

When selecting the best orbital packaging machine for your application, there are several key features to consider. Each feature impacts the machine's performance, efficiency, and suitability for your specific packaging needs.

2.1 Machine Size and Wrapping Diameter

The size of the machine and the diameter of the wrapping ring determine the maximum size of the products that can be wrapped. It's essential to choose a machine with a wrapping diameter that can accommodate the largest product in your inventory. For manufacturers dealing with long items like wooden planks or pipes, a larger wrapping diameter is necessary to ensure proper coverage.

2.2 Automation Level

Orbital packaging machines come in different levels of automation, ranging from manual and semi-automatic models to fully automated systems. A fully automated machine can significantly increase productivity by reducing the need for manual intervention, while a semi-automatic model may provide more flexibility for smaller operations.

Fully automated machines are ideal for high-volume production lines that require continuous packaging without operator involvement, while semi-automatic machines are often better suited for companies with lower production volumes or those that handle a variety of product sizes.

2.3 Film Tension Control

Maintaining the proper tension of the wrapping material is crucial to ensure that the product is securely wrapped without damaging it. Advanced tension control systems allow the machine to automatically adjust the tension based on the size and shape of the product, ensuring a consistent and reliable wrap. For industries dealing with fragile or high-value products, precise tension control is a must.

2.4 Pre-Stretch Capabilities

Pre-stretch film technology is one of the most important features to consider when looking for an orbital packaging machine. Pre-stretching the film before it is applied to the product helps to reduce material waste and improve the strength of the wrap. This feature not only enhances the overall efficiency of the packaging process but also lowers material costs.

2.5 Productivity and Speed

The speed at which the machine operates directly impacts your packaging line's productivity. Machines with higher wrapping speeds are ideal for high-volume operations that require quick turnaround times. It's important to assess your production volume and choose a machine that matches your throughput requirements without compromising on the quality of the packaging.

2.6 Customizable Settings

Flexibility is key when dealing with products of varying sizes and shapes. Customizable settings allow operators to adjust the machine’s parameters, such as wrapping speed, tension, and film usage, to meet the specific needs of each product. This feature is particularly useful for businesses that package a diverse range of items and require adaptability in their packaging process.

3. Common Packaging Challenges and How Orbital Packaging Machines Address Them

Several common challenges arise in packaging long, bulky, or irregularly shaped products. The right orbital packaging machine can address these challenges, providing solutions that improve both efficiency and product protection.

3.1 Irregular Product Shapes

Products with irregular shapes, such as furniture, aluminum profiles, or construction materials, can be difficult to wrap consistently. Orbital packaging machines are designed to handle these types of products by automatically adjusting the film application based on the product’s dimensions, ensuring complete and even coverage.

3.2 Product Damage During Transportation

One of the main reasons for investing in an orbital packaging machine is to prevent product damage during transportation. By securely wrapping the product, the machine creates a protective barrier that reduces the risk of scratches, dents, and other damage caused by handling or environmental factors such as moisture and dust.

3.3 Film Waste and Environmental Impact

Without proper control over film usage, packaging operations can generate a significant amount of material waste, which increases costs and has a negative impact on the environment. Orbital packaging machines with pre-stretch capabilities minimize film waste by optimizing the amount of material used while maintaining high levels of product protection.

3.4 Inconsistent Wrapping Quality

Manual or outdated wrapping methods can lead to inconsistent packaging, with some products receiving too little or too much film. This inconsistency can affect both product protection and the appearance of the packaging. Orbital machines offer precise and uniform wrapping, ensuring consistent quality across all packaged products.

4. Market Trends in Orbital Packaging Machines

The orbital packaging machine market is evolving rapidly, with several key trends influencing the types of machines available and the features they offer. Staying up-to-date with these trends can help businesses make informed purchasing decisions.

4.1 Automation and Smart Technology

The push for automation across industries has led to significant advancements in orbital packaging machines. Many modern machines now come equipped with smart technology, such as programmable logic controllers (PLCs) and IoT-enabled features. These technologies allow for remote monitoring, predictive maintenance, and real-time performance tracking, enabling businesses to optimize their packaging processes and reduce downtime.

4.2 Sustainability Initiatives

As businesses focus more on sustainability, the demand for eco-friendly packaging solutions is increasing. Orbital packaging machines that use recyclable or biodegradable films, as well as those designed to minimize energy consumption, are becoming more popular. Investing in a machine with sustainability features can help reduce a company’s carbon footprint and align with growing environmental regulations.

4.3 Customization and Modular Designs

Modular designs that allow for customization are also gaining traction in the market. Businesses can tailor their orbital packaging machines to meet specific production needs, adding features such as automated product feeders, integrated conveyors, or robotic arms. This flexibility ensures that the machine grows with the company’s packaging requirements and continues to provide value over time.

5. Selecting the Right Supplier for Orbital Packaging Machines

Choosing the right supplier is just as important as selecting the right machine. The quality of the supplier's service, support, and expertise can significantly impact the success of your packaging operations.

5.1 Reputation and Experience

Look for suppliers with a strong reputation in the packaging industry and a proven track record of delivering high-quality machines. Reputable suppliers will have extensive experience in providing orbital packaging solutions across various industries and can offer valuable advice on selecting the right machine for your application.

5.2 After-Sales Support

A supplier’s after-sales support is crucial for ensuring that your machine operates efficiently over the long term. Ensure that the supplier offers maintenance services, spare parts, and technical support to minimize downtime and keep your packaging line running smoothly.

5.3 Customization Options

Work with a supplier that offers customization options to tailor the machine to your specific needs. Whether you need a machine with additional features or require integration with existing systems, a flexible supplier will be able to provide solutions that meet your unique requirements.

6. Cost Considerations: Total Cost of Ownership

When evaluating the best orbital packaging machine for your application, it’s important to consider the total cost of ownership (TCO). The TCO includes not just the initial purchase price but also ongoing operational costs such as energy consumption, film usage, maintenance, and potential downtime.

6.1 Initial Investment

The upfront cost of the machine will depend on its size, automation level, and the features it offers. While entry-level machines may have a lower initial cost, higher-end models with advanced features can provide better long-term value due to increased efficiency and lower maintenance needs.

6.2 Operational Efficiency

Machines with pre-stretch capabilities and energy-saving features can significantly reduce operational costs. Over time, the savings from reduced film usage and lower energy consumption can offset the higher purchase price of a more advanced machine.

6.3 Maintenance and Downtime

Investing in a machine with a comprehensive service contract and easy access to spare parts can help reduce the risk of costly downtime. Regular maintenance ensures that the machine continues to operate at peak performance, extending its lifespan and reducing the need for expensive repairs.

7. Case Studies: Successful Implementation of Orbital Packaging Machines

To gain a better understanding of how orbital packaging machines can improve packaging processes, let’s look at some real-world case studies:

7.1 Construction Materials Manufacturer

A construction materials manufacturer struggled with the packaging of long, heavy products like steel beams and pipes. By implementing a fully automated orbital packaging machine, the company was able to increase productivity by 30%, reduce film usage by 20%, and improve product protection during transport. The investment in automation also led to a significant reduction in labor costs.

7.2 Furniture Manufacturer

A furniture manufacturer needed a solution for securely wrapping large, irregularly shaped items like sofas and tables. The company invested in a semi-automatic orbital packaging machine with customizable settings, allowing them to package products of varying sizes efficiently. This resulted in improved packaging consistency and reduced product damage during shipping.

8. Conclusion

Finding the best orbital packaging machine for your application involves a careful analysis of your packaging needs, the machine's features, and the total cost of ownership. By focusing on key factors such as automation, film tension control, and sustainability, you can make an informed decision that enhances your packaging efficiency, reduces costs, and improves product protection.

Working with a reputable supplier, ensuring after-sales support, and staying up-to-date with market trends will ensure that your investment in an orbital packaging machine delivers long-term value. With the right machine in place, you can streamline your packaging operations and achieve greater productivity in your manufacturing or logistics processes.