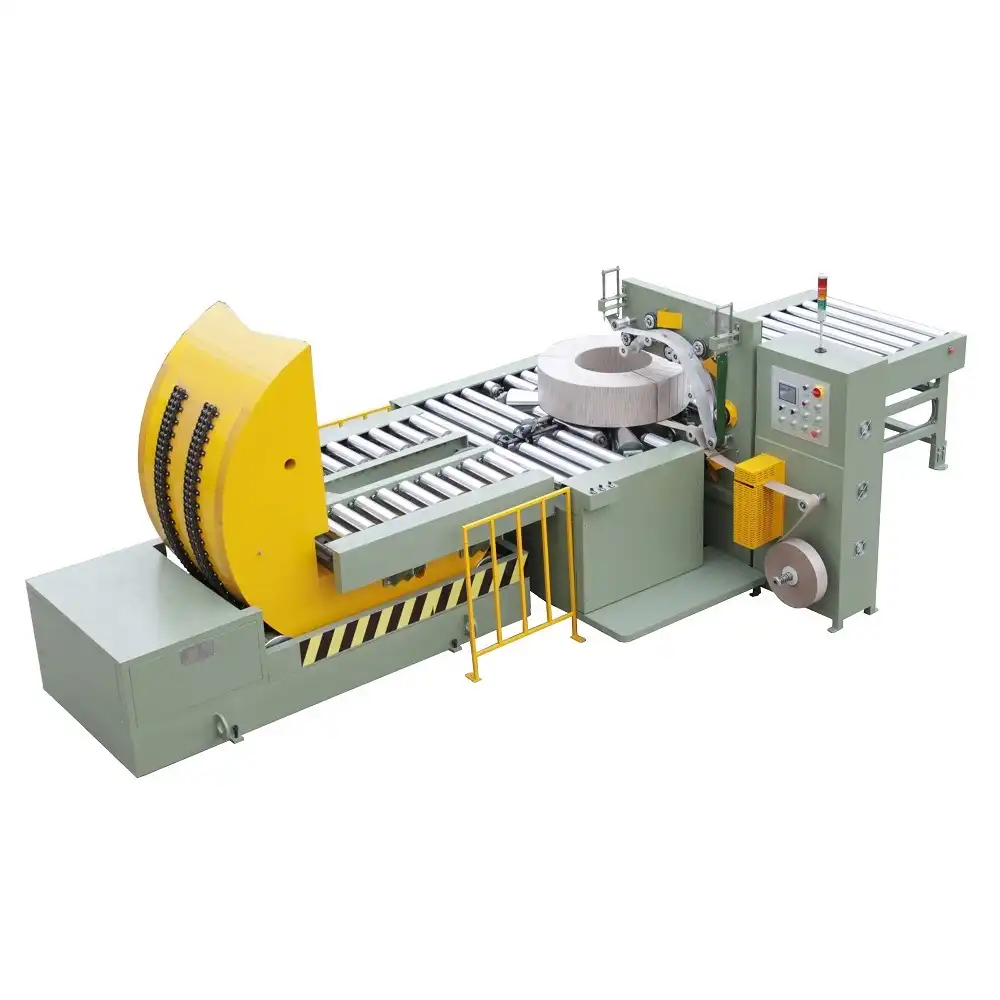

Automatic bubble film wrapping machine

This is the bubble film wrapping machine for heating plate.

Following is the special designing for meeting the customer's packaging requirement after checking the operation process with packing materials.

Heater plate: Maximum circumscribed circle 400-800mm Length: 600-2000mm Height <200mm

Weight: 5-50kg

Feeding conveyor line: 2000mm with power

Discharge conveyor line: 2000mm with power

Ring speed: 20-100r/min

Power: about 2.5kw

Power supply: 380v, 3PH. 60Hz

Packing material: PE film/stretch film

OD: 100-200mm Width: 150-200mm ID: 50mm

Bubble film: OD: 200-500mm width: 300-1000mm

1. The outer diameter of the bubble film is expanded to 1200mm

2. Increase the grating beam to detect problems, the signal density is 10mm

3. The inner diameter of the stretch film is changed to 50mm

4. The sealing and cutting knife head is widened, extending 15mm from the splint

5. The feeding direction of the stretch film roll is adjusted to the direction of the discharge conveyor line (need to be confirmed by Fengding)

6. Docking with front-line programs to realize automatic loading and unloading.

7. Solve the problem that the film is easily clamped in when the cutter is reset.

8. The shortest package is 400mm

9. The adjustment range of the installation mechanism has a larger margin

10. Adjust the beam on the bottom of the cutter cylinder to move it to a position where it does not interfere with the cutter cylinder.

11. Adjust the feeding position of the lower roll film, consider placing it on its side.

12. Consider the Teflon treatment of the cutter splint

13. Provide more information about the stretch film roll company

14. Can realize single-layer, single-piece product packaging

15. Cancel or reduce the spring pressure because it is easy to flatten the bubble film

16. Consider the outer diameter of the film roll 220-250mm

17. Consider automatic identification of the length of products of different lengths

18. When packaging small products, consider that the object is small and light, and the bubble film cannot be moved.

19. Consider SCJ for down-pressing cylinder

20. Consider the PVC belt line for the heaviest object 55kg. Lightest object weight 4.8Kg