Automatic Cable Wire Winding and Packing Line

Application

The automatic cable packaging line is designed for off-line cable packaging. It efficiently counts cable lengths, performs automatic cutting, creates coils, applies polypropylene strapping, and conducts heat shrinking for coil packaging. All components comply with CE guidelines and are built using the latest technology and design standards for industrial applications.

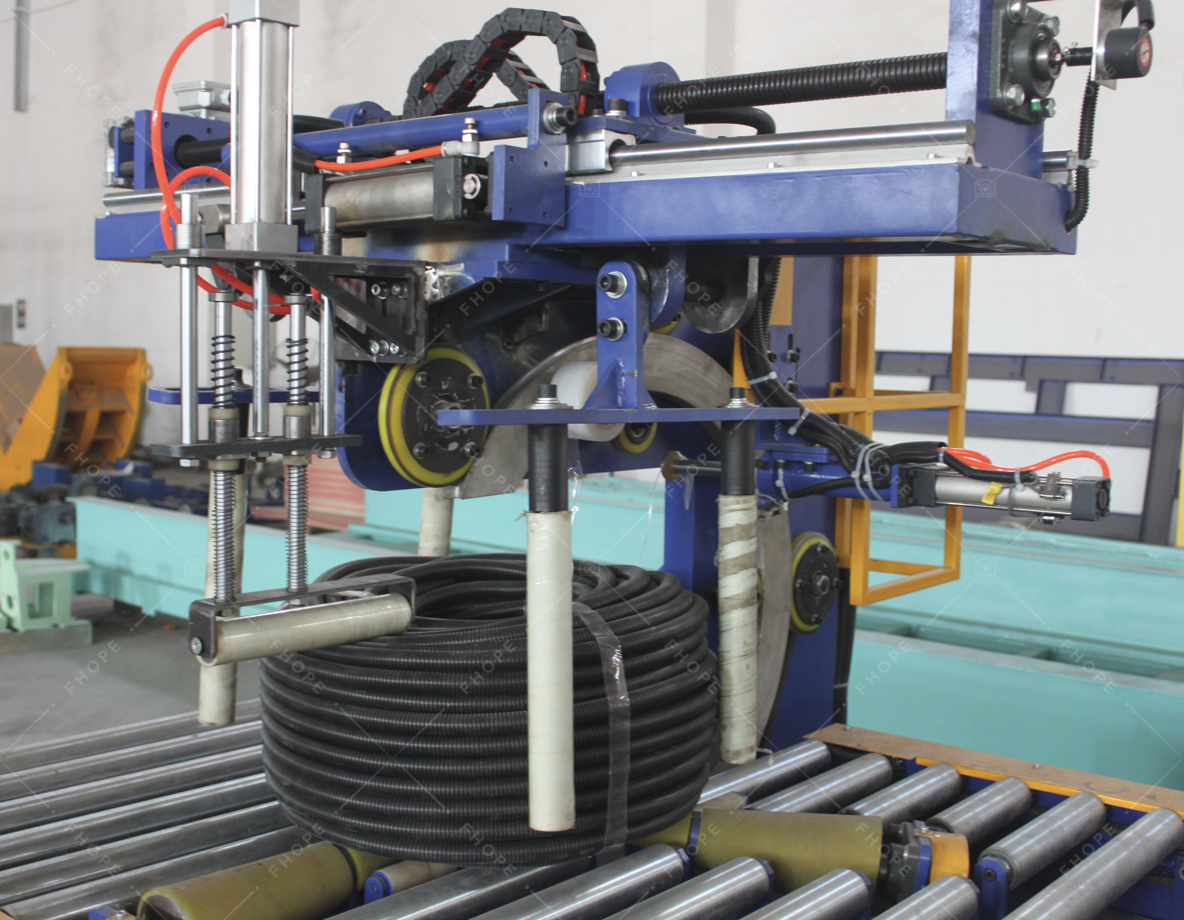

Automatic winding machine:

1.Automatic Winding:

The system is capable of quickly and automatically winding cables into neatly organized coils, enhancing production efficiency.

2.Length Counting:

Equipped with a length counting feature, it continuously monitors the length of the wound cable in real time, ensuring accuracy.

3.Adjustable Functionality:

The system can wind cables of different specifications, accommodating a variety of production needs.

Key Features:

(1).High Precision Control: Utilizes an advanced PLC control system to ensure stability and precision during the winding process.

(2).Adjustable Coil Diameter: The winding head's diameter can be adjusted to fit different cable sizes, accommodating various cable types.

(3).Securing Device: Includes a securing device to maintain cable stability during winding, preventing loosening.

(4).User-Friendly Operation: Designed with an intuitive interface for easier operation, reducing training time.

(5.)Safety Protection: Features built-in safety mechanisms to prevent accidents during operation.

(6).Noise Design: An optimized mechanical structure reduces noise during operation, enhancing workplace comfort.

Automatic strapping machine:

The strapping machine dispenses, tightens, and seals polypropylene straps while the coil is in place. It automatically straps and joins the ends with adjustable tension through secure heat welding. The motor switches off automatically when the strap is inserted.

Features:

(1).Dual Strapping Points: Two positions for strip strapping through the coil eye.

(2).Automated Control: Program-controlled operation for efficient automatic strapping.

(3).Automatic Coil Positioning: Adjusts automatically for different coil sizes.

(4).Adjustable Tension: Tension can be customized for various cable coils.

(5).Integration: Connects seamlessly with the coiling machine.

(6).Strapping Height: Minimum strapping height of 44.5 mm.

Technical parameter:

Coiling size:

|

ID: 140-250 mm (Fixed)

OD: 200-600mm

Height: 60-180mm

|

Cable diameter:

|

2-20mm

|

Line speed:

|

200m/min

|

Coiling speed:

|

2-2.5 coils/min

|

Air supply:

|

6bar

|

Coil feed style mode:

|

Hold coil type

|

Meter counter:

|

0.01m-500m

|

Power volt8ge:

|

AC 380V, 50HZ, 3 phase

|

Automatic coil shrinking machine:

The system features automatic sealing capabilities. The length of the fold film can be adjusted as needed. An automatic film feeding system is equipped with sensor control for efficiency. The system operates without manual intervention, with sealing and shrinking occurring automatically.

Ensures a clean sealing process with no residual packing material.The system can be adjusted for different product sizes.

Features:

(1). Variable Sealing Speed: Sealing speed can be adjusted based on the type of packing material used.

(2).Constant Temperature Heat Sealing: The heat sealing and cutting system operates at a constant temperature, suitable for POF films.

(3).Precise Temperature Control: The cutter is equipped with precise temperature control for optimal performance.

(4).Dual Feeding Modes: Users can choose between automatic and manual feeding options.

(5).Adjustable Forming Device: The forming device can be changed to accommodate different product sizes.

(6).Safety Guardrail: Includes protective guardrails to ensure safe operation.

(7).Synchronized Control: Conveyor and sealing operations are synchronized through programmed controls.

(8).Adjustable Conveyor Height: The height of the conveyor can be adjusted for convenience.

(9).Variable Conveyor Speed: Conveyor speed is adjustable to meet specific requirements.

(10).Synchronization with Bagging Station: The system synchronizes seamlessly with the bagging and sealing station.

(11).Accurate Temperature Control: Features temperature compensation for precise temperature regulation.

(12).Robust Construction: Built with heavy-duty, high-quality components for durability, ensuring continuous operation with minimal maintenance.

(13).Adjustable Conveyor Speed: The conveying speed can be easily adjusted to meet specific requirements.

(14).Energy-Efficient Heating: The recirculation heating system reduces electrical energy consumption by minimizing heat loss.

(15).Cooling Devices: Equipped with cooling devices for efficient temperature management.

Automated Robot Coil Stacking System

The automated robot coil stacking system is designed as an efficient and precise solution for coil stacking. This system can automatically handle and stack various types of coils, aiming to improve production efficiency and reduce manual intervention. Below are the main functions and features of the system:

Functions:

(1).Automatic Stacking: The robot can automatically identify and stack coils of different specifications, ensuring neat placement.

(2).Flexibility: Adapts to various coil sizes and types to meet diverse production needs.

(3).Efficient Transport: Quickly transports coils to the stacking position through an automated conveyor system.

Key Features:

(1).Intelligent Recognition: Equipped with advanced sensors and vision systems to accurately identify coil positions and sizes.

(2).High Efficiency: The robot operates at a fast speed, significantly enhancing production efficiency.

(3).Safety Design: Built-in safety mechanisms ensure the safety of personnel during operation.

(4).User-Friendly Operation: The control interface is designed for ease of use, making operation and setup straightforward.

(5).Strong Stability: Constructed with heavy-duty materials to ensure stability and durability under high loads.

(6).Energy-Efficient and Eco-Friendly: Designed with a focus on energy efficiency, reducing power consumption and meeting environmental standards.

A flexible robot, making it ideal for a variety of applications, ranging from spot welding to material handling. It has an incredibly capable thin wrist that delivers excellent cycle times, making it perfect for nimble spot welding. FANUC R-2000iC/165F has been thoughtfully designed to maximize use of work space and be in closer proximity to other robots.