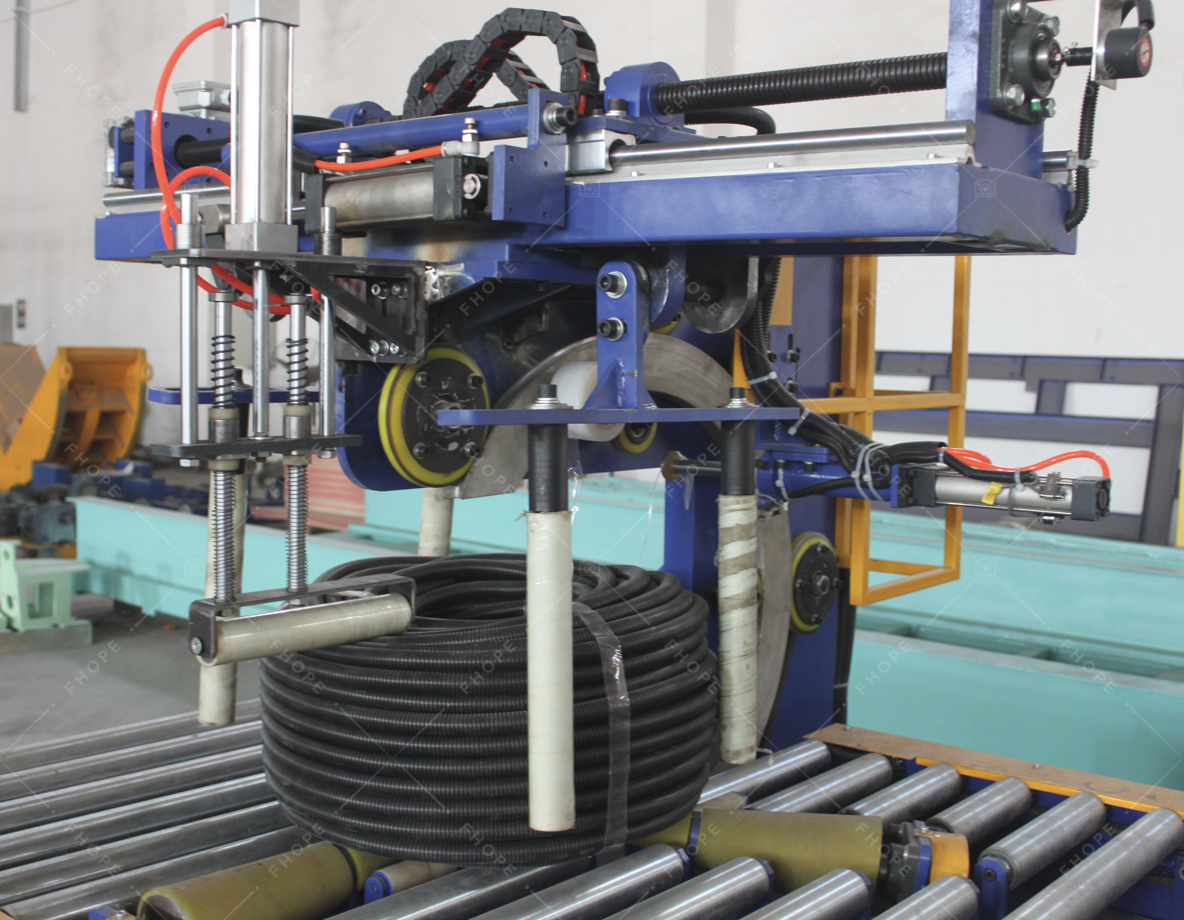

Automatic Cable Winding And Packing Machine

Function:

This equipment automates the processes of calculating cable length, coiling, and cutting. It also facilitates the automatic transfer of the coiled cable to the next processing station, such as film wrapping or shrinking machine can be added for coil packaging. The parameters can be configured through the PLC control program.

Features:

1. Automated Control: Utilizes PLC and HMI for seamless automatic operation.

2. User-Friendly Interface: Parameters can be easily set in English via the control program.

3. Coiling Diameter adjustment: Coiling outer diameter (OD) is adjustable to accommodate different requirements.

4. Customizable coiling Length: Cable cutting length can be modified according to specifications.

5. Stabilizing Guards: Equipped with two protective guards to secure move the coiled tube safely.

6. Automatic Error Detection: Features an alarm system that activates in case of malfunctions.

7. Position Detection: Sensors automatically detect the position of the tube.

8. Stable Coiling Mechanism: A pressing device ensures that the pipe coil remains fixed and stable during processing.

9. Tension Control: Maintains tension to prevent deformation during coiling.

10. Integrated Tension Control: Tension control is also integrated into the packing line.

11. Automatic Unwinding: The unwinding machine regulates tension and synchronizes tube feeding with coiling.

12. Reel Compatibility: Different coil reels must be used based on the specific inner diameter requirements.

Technical parameter:

Coiling size:

|

ID: 140-250 mm (Fixed)

OD: 200-600mm

Height: 60-180mm

|

Cable diameter:

|

2-20mm

|

Line speed:

|

200m/min

|

Coiling speed:

|

2-2.5 coils/min

|

Air supply:

|

6bar

|

Coil feed style mode:

|

Hold coil type

|

Meter counter:

|

0.01m-500m

|

Power voltage:

|

AC 380V, 50HZ, 3 phase

|