The Collection Page of The Aluminum Profile Packaging Solutions

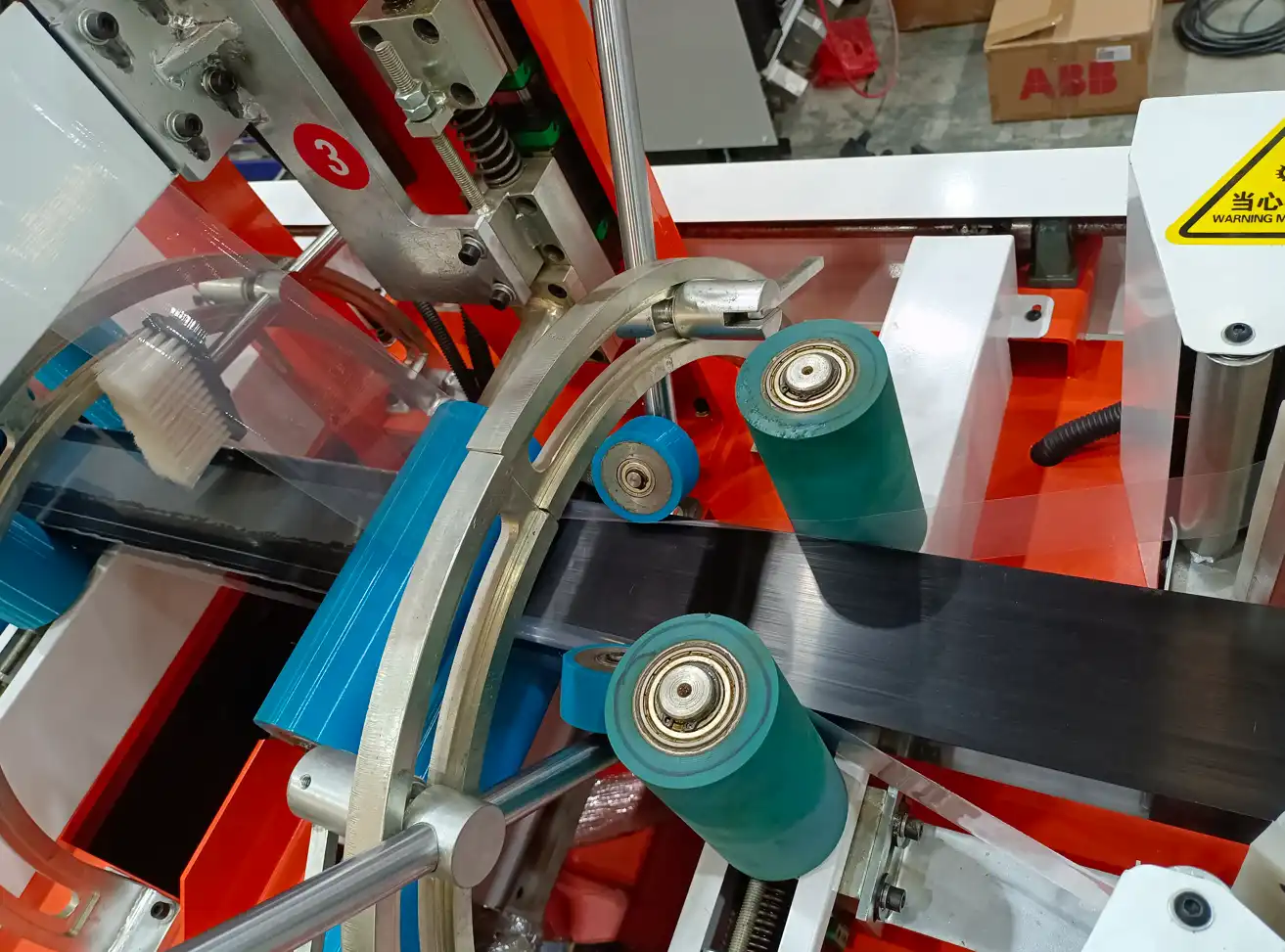

The design of the automatic aluminum profile packing machien and automatic packing line is completely based on user’s actual manufacturing needs. It is an aluminum bundle packing equipment which aims to provide on line packing solution. It is realize the following aspects. Automatic aluminum profile packing solution including profile banding, aluminum strapping, profile wrapping, aluminum bundle making... Following are individual machine available from FHOPEPACK. 1) Aluminum bundle strapping machine 2) Aluminum wrapping machine The wrapping machine providing film stretch wrapping solution for the aluminum profile and bundle. 3) Aluminum bundling machine It is equipment for aluminum bundle making, It is an integrated system with forks, aluminum bundle moving lifters, roller conveyor allows to bundle making layers by layers for the packaged aluminum profiles according program setting for aluminum coming from the wrapping machine. Setting the length, layers no., and pcs of aluminum on touch screen. 4) Aluminum bundle stretch wrapper The aluminum bundle stretch wrapper connect with the bundle maker for wrapping the formed bundle by stretch plastic film. It providing the packaging for transition of the bundle through the main body of the machine. It is possible to setting a wrapping program vary from orver wrapping in correspondence with certain points of the package.