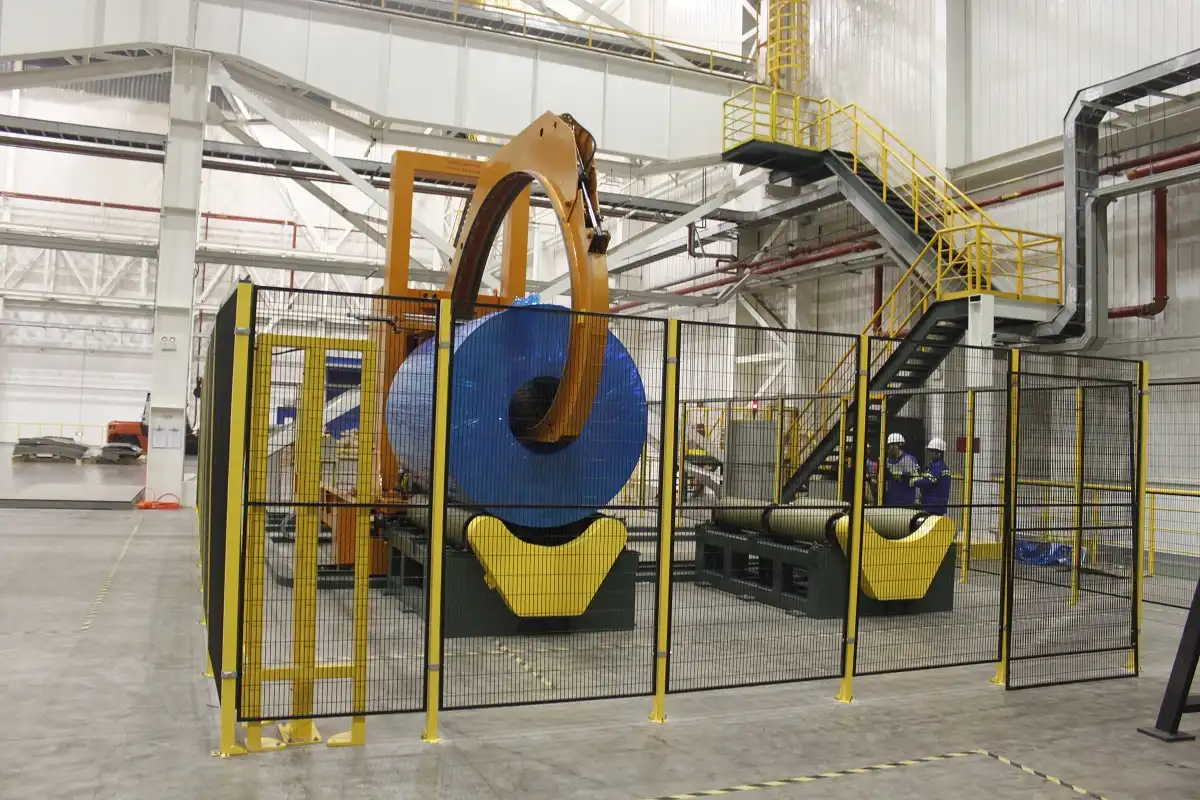

The shuttle change system for aluminum coil wrapping machines is a game-changing technology that greatly simplifies the process of switching shuttles during the aluminum coil wrapping process.

The system is designed to work with machines that have moving shuttles that dispense wrapping material along a track.

With the shuttle change system, changing shuttles has never been easier.

The system allows for seamless transitions during the wrapping process, ensuring that the machine can operate continuously without any interruption.

This results in increased efficiency and productivity, as well as a higher throughput.

The shuttle change system enhances the wrapping machine's performance and reduces the risk of downtime due to shuttle changes.

It eliminates the need for manual interventions, which can be time-consuming and increase the likelihood of errors and accidents.

The system is easy to install and can be integrated into existing aluminum coil wrapping machines.

It is also easy to operate, with a user-friendly interface that allows operators to switch shuttles quickly and efficiently.

Technical parameter:

Object material

|

Aluminum coil

|

Coil width(W)

|

600~2000mm

|

Coil outer diameter(OD):

|

900-2200mm

|

Coil inner diameter(ID)

|

450-610mmm

|

Coil weight

|

1000-25000kg

|

Packing material

|

Paper/VCI film/LLDPE stretch film/PVC/Opaque plastic/

ID:76mm OD:100-200mm Width:200-250mm

(The precise size will be confirmed after designing)

|

Shutter speed

|

app.2-3m per minute

|

Overlap rate

|

20%~90%

|

Power

|

app 12.5Kw

|

Power supply

|

380V,Three-phase five line

|

Hydraulic supply

|

140bar

|

Air supply

|

5-6kgf/cm2

|