The Collection Page of The Aluminum Profile Packaging Solutions

The design of the automatic aluminum profile packing machien and automatic packing line is completely based on user’s actual manufacturing needs. It is an aluminum bundle packing equipment which aims to provide on line packing solution. It is realize the following aspects. Automatic aluminum profile packing solution including profile banding, aluminum strapping, profile wrapping, aluminum bundle making... Following are individual machine available from FHOPEPACK. 1) Aluminum bundle strapping machine 2) Aluminum wrapping machine The wrapping machine providing film stretch wrapping solution for the aluminum profile and bundle. 3) Aluminum bundling machine It is equipment for aluminum bundle making, It is an integrated system with forks, aluminum bundle moving lifters, roller conveyor allows to bundle making layers by layers for the packaged aluminum profiles according program setting for aluminum coming from the wrapping machine. Setting the length, layers no., and pcs of aluminum on touch screen. 4) Aluminum bundle stretch wrapper The aluminum bundle stretch wrapper connect with the bundle maker for wrapping the formed bundle by stretch plastic film. It providing the packaging for transition of the bundle through the main body of the machine. It is possible to setting a wrapping program vary from orver wrapping in correspondence with certain points of the package.

Aluminum profile packing line

-

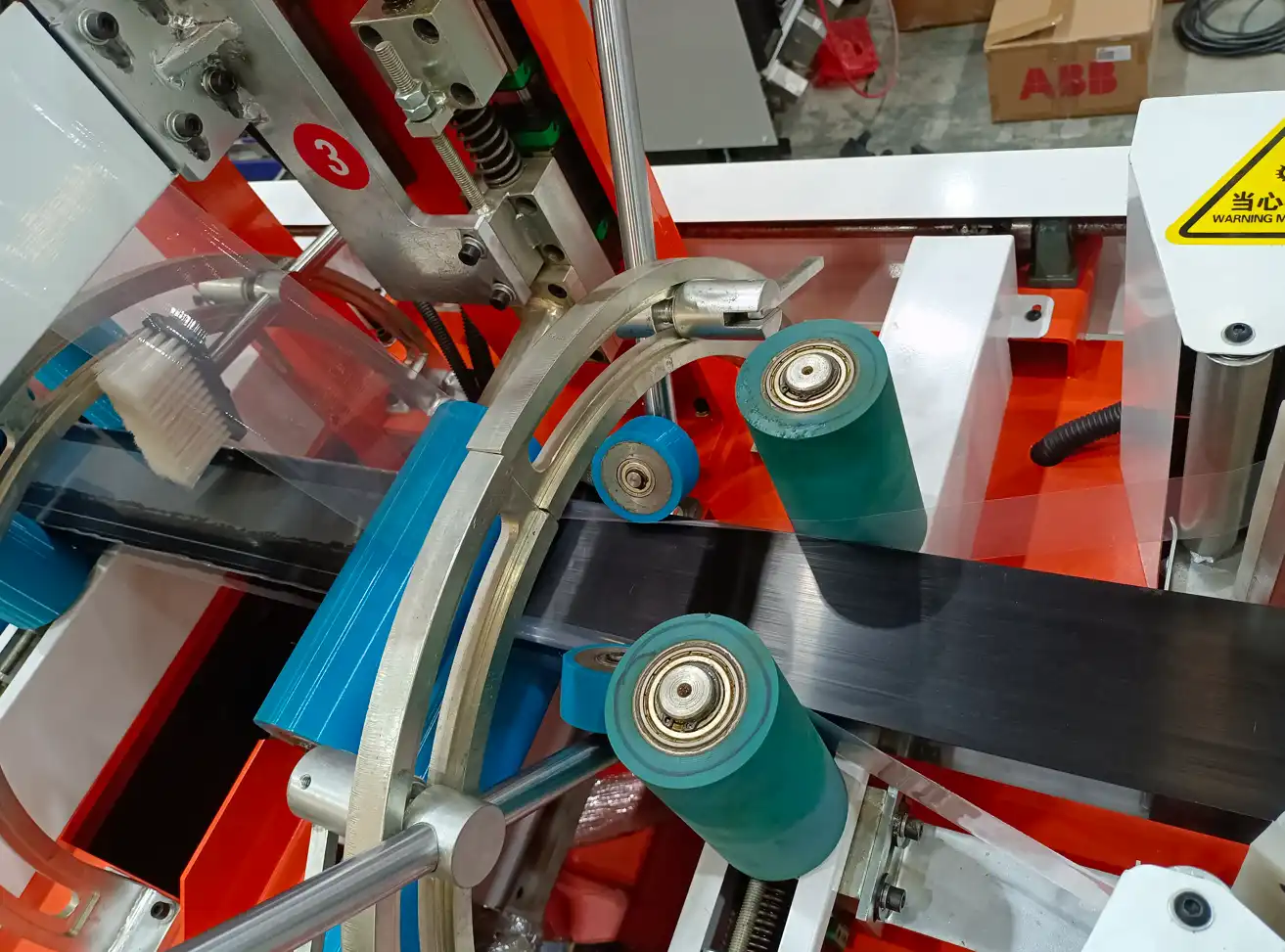

Aluminum profile packing line with timber feedingMachine is designed with a compact steel frame. Replacement of wrapping material is carried out quickly and easily . Profiles are drawn through the machine by a series of rollers which open and close automatically, allowing bundles with different dimensions to pass through automatically without stopping the machine . Powered roll...

-

Aluminum profile paper covering machineAutomatic profile packing machine is an advanced solution designed for the automatic feeding and covering of aluminum profiles with paper and plastic sheets. With a length of 6m and a width of 200mm, this machine streamlines the packaging process and increases productivity. With its reliable performance and innovative features, o...

-

Aluminum profile stacking machineAluminum profile stacking machine is an advanced solution designed for automatic counting, layer making, and storage of aluminum profiles. This machine features automatic timber feeding and stacking of the profiles layer by layer, streamlining the stacking process and increasing productivity. With its reliable performance and inn...

-

Aluminum Profile Sub-Bundle Wrapping MachineAluminum bundle wrapping line is an advanced solution designed specifically for the wrapping of aluminum bundles. With a maximum speed of 40m per minute, this machine features automatic film and paper wrapping and tapping, streamlining the packaging process and increasing productivity. With its reliable performance and innovative...

-

Automatic aluminum wrapping and tapping machineThis whole line consisted with sub-bundle strapping, bundle transferring, bundle wrapping and tapping sections. High level of automation, synchronized tapping mechanism enables non-stop characteristic. Top efficient machinery in the industry....

-

Automatic aluminum profile bagging machineThis is an automatic aluminum profile bag packing machine designed for steel tube feeding & bagging operation. It includes steel tube feeding, bagging, out-feeding and etc. It is a set of efficient, convenient and safe packaging machinery for steel tube bagging. ...

-

automatic profile packing lineAutomatic aluminum profile packing line is a customizable solution designed to meet the specific needs of businesses in terms of workspace, product handling, and stacking. This system is integrated with strapping, wrapping, and stacking equipment, providing businesses with a comprehensive and efficient solution for their packagin...

-

Automatic profile tapping machineThe machine is designed to operate continuously with an operating speed of up to 40 m/min with suitable in-feed and out-feed roller conveyors. It is an automatic equipment with automatic synchronize cutter driven by servo system for cutting the film between the profile to make the machine running continually....

-

Extruded aluminum profiles packaging lineOur extruder aluminum packing line is specifically designed to apply a strip of adhesive film along the top and bottom sides of the profile. This machine is designed to operate continuously, streamlining the packaging process and increasing productivity. With its advanced features and reliable performance, our extruder aluminum p...

-

Automatic aluminum profile film applicatorAutomatic protective film applicator for aluminum profile to save the labor In the aluminum profile production, the profile surface protection is the important procession after extruding. The general protective way is by film and tape covering which needs two people operation, one for machine running and profile infeeding, one fo...

-

Automatic aluminum profile stacker | for sand blasting profilAutomatic aluminum profile stacker is designed for sandblasting production lines and is a comprehensive solution for layer making, spacer feeding, handling, and filling into baskets. With its advanced features and efficient operation, this machine requires only one person to operate, reducing labor costs and increasing productivi...

-

Automatic aluminum profile paper packing machineAutomatic paper or plastic sheet covering machine is designed to provide reliable and efficient packaging for aluminum profiles. This machine is a comprehensive packing line that includes material feeding, cutting, covering, and tapping, streamlining the packaging process and increasing productivity. With its advanced features an...

What are the Main Parts of the Automatic Aluminum Profile Packing Line?

- Aluminum Profile film applicator:It is an innovative packaging solution that automatically applies protective film to aluminum profiles surface with automatic cutter in high speed upto 40-60m per minute.

- Aluminum Profile Sub-Bundle Binding and Wrapping Machine:This equipment binds smaller groups of aluminum profiles together, making handling easier and more efficient during the packing process. It also wraps these bundles for added protection by stretch film, paper.

- Aluminum Bundle Making Machine: This machine forms larger bundles of aluminum profiles from small bundle by gathering and aligning them according to specified dimensions. The square bundle shaping to make it ready for the next packing stage.

- Bundle Strapping and Wrapping Machine:Once the big bundle is formed, this machine straps and wraps them to secure the profiles in place, preventing movement during transit. This step is crucial for maintaining the integrity of the aluminum into bundle for transportation.

- Others:Customized Solutions: Depending on specific needs, additional machines such as small bundle bagging machines and bundle timber packing machines can be integrated into the line for enhanced flexibility.

C. What Are the Benefits of an Aluminum Profile Packing Line?

- Increased Efficiency: Automating the packing process from signale profile into bundle packaging that significantly reduces the 50%-80% time required to package products, enabling higher throughput.

- Reduced Labor Costs:One worker required only for the packing process, cutting operational expenses.

- Improved Product Quality:Consistent strapping and wrapping ensure that aluminum profiles are well-protected, reducing damage during storage and transportation.

- Enhanced Flexibility:The line can be tailored to accommodate various sizes and types of aluminum profiles, allowing manufacturers to adapt to changing market demands.

- Streamlined Workflow: Integrating multiple machines into a cohesive line by conveyor, lifter, crane... It reduces handling times and enhances overall productivity.

- Custom Solutions:The ability to incorporate customized machinery in the handling way, automation level,allows companies to meet specific production requirements efficiently.

D. How to Choose the Proper Aluminum Profile Packing Line?

- Assess Production Volume: Determine the daily or hourly output needed to select an appropriate machine capacity.

- Evaluate Tube Specifications: Consider the dimensions and weights of the steel tubes to ensure compatibility with the machines.

- Consider Automation Levels:Decide how much automation is necessary based on available workforce and production goals.

-

Check for Customization Options:Look for machines that can be tailored to specific requirements.

- Space Considerations:Ensure that the layout fits within your facility's constraints.

- Budget: Establish a budget that includes not only purchase costs but also installation and maintenance.

Why Choose FHOPE for Aluminum Profile Packing Line?

- Industry Expertise:FHOPE specializes in developing tailored packing solutions that meet diverse customer needs. Showcase here

- High-Quality Components:Our machines are constructed from durable materials, ensuring longevity and reliability.

- Comprehensive Support Services: We offer on-site installation, training, and ongoing technical support for smooth operations.

- Innovative Technology:Our packing lines incorporate the latest automation technologies both in mechanical and control system to maximize efficiency.

- Proven Track Record: FHOPE has a history of successful installations across various steel tube packing line, ensuring customer satisfaction.

- Competitive Pricing:We offer high-quality solutions at competitive prices, providing excellent value for your investment.

Frequently Asked Questions

We've compiled key FAQs about coil packing lin projects for your convenience. If you don't find your question, call us at +8613951501635 or email info@fhopepack.com.

> How long does it take to install an aluminum profile packing line?

> Can the packing line handle different types of aluminum profiles?

> What maintenance is required for the packing line?

> Is training provided for operating the machinery?

> Can the line be integrated with existing systems?

> What is the warranty period for FHOPE machines?

> Are spare parts readily available?

>How can I get a quote for a custom packing line?

Download

|

|

|

|

| E200 | E300 | E400 | E1000/1400 |

SHOWCASE & NEWS

Product Inquiry

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635