1.What Labeling and Identification Methods Are Used in Steel Wire Packing?

Steel wire packing relies on effective labeling and identification to ensure traceability, manage inventory, and provide essential information to handlers and end-users. From simple tags to advanced digital systems, various methods cater to different needs and scales of operation within the steel industry. Proper labeling is crucial for efficient logistics and maintaining product integrity.

Labeling and identification methods in steel wire packing primarily include physical tags attached to bundles, ink jet printing directly onto packaging materials, and increasingly, RFID and barcode systems for digital tracking. These methods ensure clear product identification, batch tracking, and efficient inventory management throughout the supply chain.

Effective labeling is not merely an operational necessity; it is a cornerstone of quality assurance and customer satisfaction in the steel wire industry. Understanding the diverse methods available is key to optimizing packing processes and maintaining a competitive edge. Let’s delve into the specifics of these methods and their applications in steel wire packing.

2. Physical Tagging and Labeling in Steel Wire Packing

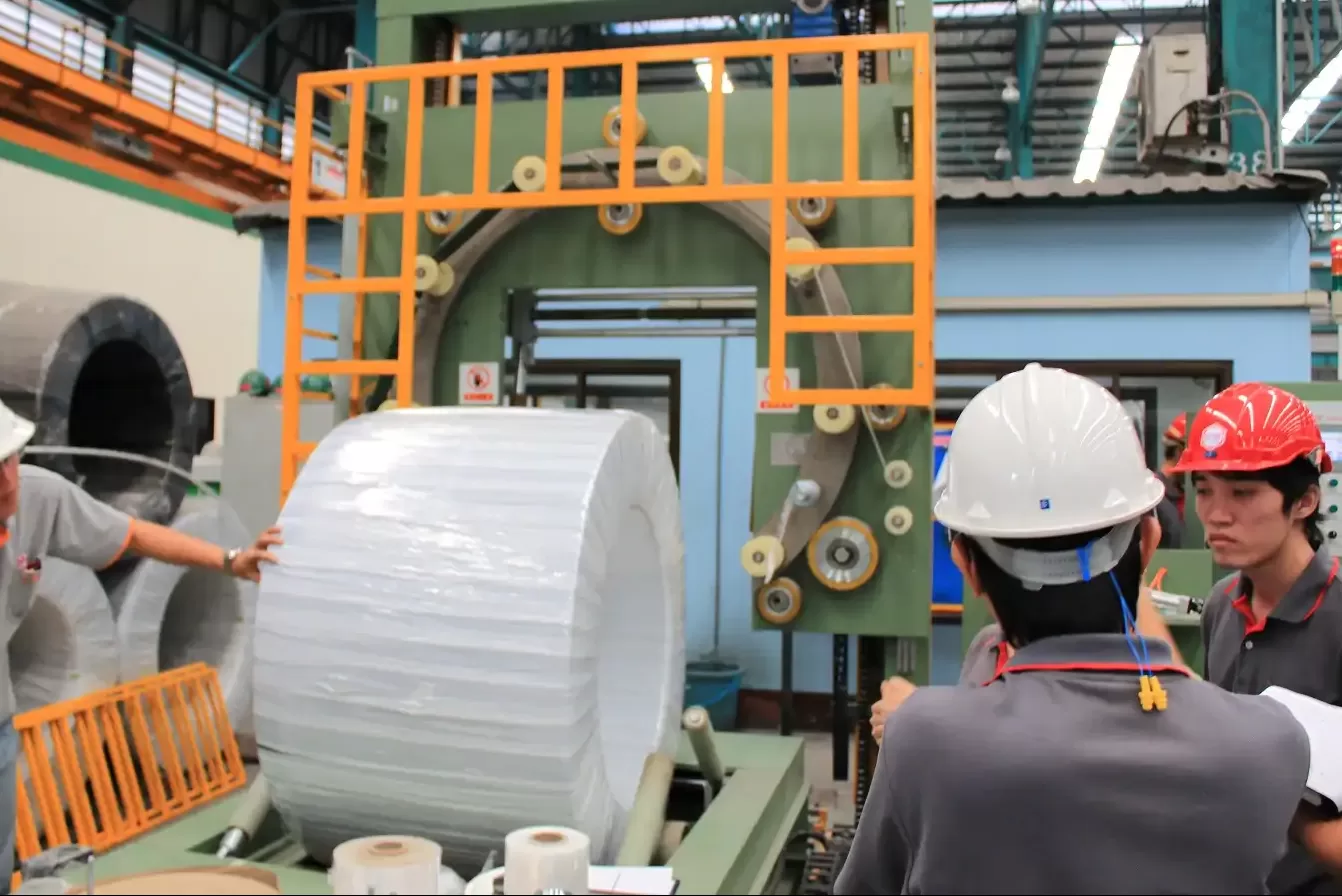

Physical tags remain a fundamental method for labeling steel wire packing, offering a direct and visually accessible means of identification. These tags, attached to wire coils or bundles, convey critical information directly at the point of handling and storage. Durability and clarity are key features of effective physical tagging.

Physical tags in steel wire packing commonly utilize durable materials like metal or plastic, featuring stamped, embossed, or printed information. These tags are securely affixed to wire bundles using steel wire or robust fasteners, ensuring they withstand harsh environmental conditions and handling. Information typically includes product grade, size, batch number, and origin.

While digital methods gain traction, physical tags provide a reliable, immediate form of identification, especially in environments where digital infrastructure may be limited or challenging. However, the effectiveness of physical tagging can be significantly enhanced when integrated with digital systems.

Enhancing Physical Tags with Digital Integration: Bridging the Gap

Physical tags, while straightforward, can be labor-intensive to manage and prone to manual errors in data entry. Integrating them with digital systems offers a hybrid approach that leverages the strengths of both methodologies. This integration primarily involves linking physical tags to digital records, often through unique identifiers printed on the tags.

Barcodes and QR Codes on Physical Tags

Adding barcodes or QR codes to physical tags allows for quick and accurate data capture using scanners or mobile devices. This bridges the physical and digital realms, enabling efficient tracking of tagged wire bundles within inventory management and tracking systems.

| Feature | Barcode | QR Code |

|---|---|---|

| Data Capacity | Limited, primarily alphanumeric | High, alphanumeric, numeric, binary, Kanji |

| Readability | Requires line-of-sight scanning | Readable from various angles |

| Error Correction | Limited | High error correction capability |

| Use Cases | Product identification, simpler data needs | Complex data, URLs, versatile applications |

RFID Integration with Physical Tags

Radio-Frequency Identification (RFID) technology further enhances physical tags by embedding RFID chips within them. These chips can store more extensive data than barcodes and can be read wirelessly, even without direct line of sight. This is particularly beneficial in large warehouses or outdoor storage areas where scanning individual tags can be cumbersome.

| Feature | Barcode/QR Code Tags | RFID Tags |

|---|---|---|

| Data Capture | Requires manual scanning, line of sight | Wireless, can read multiple tags at once |

| Data Capacity | Limited by tag size | Higher data capacity, rewritable |

| Durability | Dependent on tag material | Encapsulated chip, more resistant to damage |

| Read Range | Short, scanner dependent | Longer range, adjustable |

| Cost | Lower per tag | Higher per tag, reader infrastructure cost |

| Best Use Cases | Direct product scanning, retail, basic tracking | Automated inventory, asset tracking, robust environments |

By combining the tangible benefits of physical tags with the data management capabilities of digital systems through barcodes, QR codes, or RFID, steel wire packers can achieve a more robust and efficient labeling and identification process.

3. Ink Jet and Direct Marking Methods for Steel Wire Packing

Ink jet printing and direct marking techniques offer an alternative to tags by applying identification directly onto the steel wire packaging itself. These methods are particularly useful for applying batch numbers, logos, or other variable data during the packing process, streamlining operations and reducing material costs associated with separate tags. The choice of ink and marking method is crucial to ensure legibility and durability in the often-harsh environments of steel handling and storage.

Ink jet printing and direct marking in steel wire packing involve using specialized inks and printers to apply labels, codes, and information directly onto wrapping films, straps, or even the wire itself. These methods provide real-time customization, allowing for variable data like batch numbers and dates to be printed on demand. Durability is achieved using industrial-grade inks resistant to abrasion, UV exposure, and temperature variations.

Direct marking methods not only enhance efficiency but also contribute to sustainability by reducing the need for additional labeling materials. However, careful consideration must be given to ink adhesion, print clarity, and the longevity of the markings under typical steel wire handling conditions.

Technical Considerations for Ink Jet and Direct Marking

Implementing ink jet or direct marking successfully in steel wire packing requires attention to several technical details. These include selecting the right type of printer and ink, ensuring proper integration with the packaging line, and maintaining print quality over time.

Ink and Printer Selection

The choice of ink is paramount. It must be compatible with the packaging material (e.g., plastic film, steel straps, cardboard) and resistant to the environmental conditions the steel wire will face. Common ink types include:

- Solvent-based inks: Fast-drying, durable, good adhesion on non-porous surfaces.

- UV-curable inks: Extremely durable, excellent resistance to abrasion and chemicals, cured by UV light.

- Water-based inks: Environmentally friendly, suitable for porous materials like cardboard, less durable than solvent or UV inks.

Printers must be robust enough for industrial environments and capable of high-speed operation to keep pace with packaging lines. Continuous Ink Jet (CIJ) and Thermal Ink Jet (TIJ) printers are commonly used.

Integration with Packaging Lines

Seamless integration into existing packaging lines is essential for efficiency. Printers need to be positioned to mark packaging accurately as it moves along the line. This often involves:

- Sensors: To detect the presence of packaging and trigger printing.

- Synchronization: Matching printer speed to line speed for consistent print placement.

- Data Integration: Connecting printers to central databases for variable data input (batch numbers, dates, etc.).

Maintaining Print Quality

Consistent, legible printing is crucial for effective identification. Factors affecting print quality include:

- Nozzle maintenance: Preventing clogging and ensuring consistent ink flow.

- Regular cleaning: Removing dust and debris from printer heads and sensors.

- Ink monitoring: Checking ink levels and quality to avoid faded or inconsistent prints.

By carefully addressing these technical considerations, steel wire packers can leverage ink jet and direct marking methods to achieve efficient, cost-effective, and durable labeling solutions.

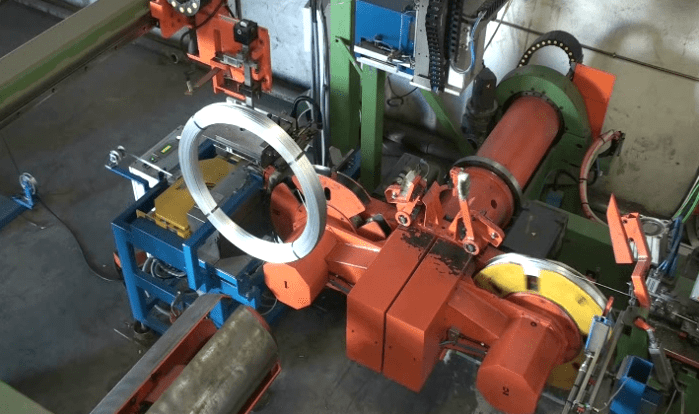

4. Digital and Automated Identification Systems in Steel Wire Packing

The increasing demand for traceability and efficiency in steel wire packing is driving the adoption of digital and automated identification systems. These systems, leveraging technologies like RFID and barcode scanning, offer real-time data capture, reduced manual intervention, and enhanced inventory management capabilities. Automation in labeling and identification represents a significant step towards optimizing supply chain visibility and operational efficiency.

Digital and automated identification systems in steel wire packing utilize technologies such as RFID and barcode scanning to streamline data capture and inventory management. These systems enable automatic identification of wire bundles as they move through packing and storage processes, providing real-time data on location, quantity, and status. Integration with warehouse management systems (WMS) and enterprise resource planning (ERP) enhances overall supply chain visibility.

The shift towards digital identification is not just about efficiency; it’s about creating a more transparent and responsive supply chain, enabling quicker responses to customer demands and tighter control over product flow.

Key Aspects of Digital Identification Systems in Steel Wire Packing

| Aspect | Description | Benefits |

|---|---|---|

| Automated Data Capture | RFID readers and barcode scanners automatically capture identification data without manual scanning. | Reduced labor costs, faster processing times, minimized data entry errors. |

| Real-Time Tracking | Systems provide up-to-the-minute information on the location and status of each wire bundle. | Improved inventory accuracy, proactive stock management, enhanced traceability. |

| Data Integration | Seamlessly integrate with WMS and ERP systems for comprehensive data management and reporting. | Streamlined operations, better decision-making, improved supply chain visibility. |

| Enhanced Traceability | Detailed tracking of each batch from production to delivery, crucial for quality control and issue resolution. | Faster recall processes if needed, improved product accountability, enhanced customer trust. |

| Improved Efficiency | Automating identification processes speeds up packing, warehousing, and shipping operations. | Increased throughput, reduced bottlenecks, optimized resource utilization. |

Automated systems represent the future of steel wire packing identification, offering scalability and precision that traditional methods struggle to match. The investment in such systems often yields significant returns through operational efficiencies and improved supply chain management.

Conclusion

Choosing the right labeling and identification methods for steel wire packing is a critical decision impacting operational efficiency, traceability, and overall supply chain management. From the enduring reliability of physical tags to the cutting-edge capabilities of digital systems, the industry offers a spectrum of solutions tailored to diverse needs and scales. The trend is clearly towards greater automation and digital integration, promising enhanced visibility and control in the steel wire supply chain. Embracing these advancements is key for steel wire manufacturers and distributors aiming for operational excellence and a competitive edge in the global market.