Facing the challenges of heavy steel coil handling in slitting service centers can be daunting. It often results in labor-intensive processes, inefficient workflows, and safety concerns. But worry no more. With the right coil wrapping machine, you can streamline your operations, reduce manual handling, and increase efficiency remarkably.

A coil wrapping machine minimizes steel coil handling by automating the wrapping process, enhancing efficiency, and ensuring safe and damage-free delivery of coils. This device reduces human intervention, optimizes packaging speed, and stabilizes the coils, thus effectively addressing common operational bottlenecks in slitting service centers.

You might ask how exactly a coil wrapping machine benefits my slitting service center. Imagine a streamlined process where each coil is automatically wrapped and prepared for transport with consistent quality. Transitioning to automated solutions not only elevates your productivity but also allows your workforce to focus on more strategic tasks. Let’s delve into the specifics of how this amazing technology transforms coil handling.

1. How Does a Coil Wrapping Machine Minimize Steel Coil Handling?

In the slitting service center, the physical labor involved in steel coil handling can be overwhelming. The tension, safety concerns, and unpredictability often complicate operations. But there’s a more efficient way to reverse this.

A coil wrapping machine minimizes steel coil handling by taking over the repetitive tasks of wrapping and securing the coils. By automating the process, it drastically cuts down on manual labor and ensures a uniform wrapping quality—factors crucial for reducing damage during transportation. This leads to improved safety and enhanced operational efficiency within slitting centers.

The Mechanics Behind the Technology

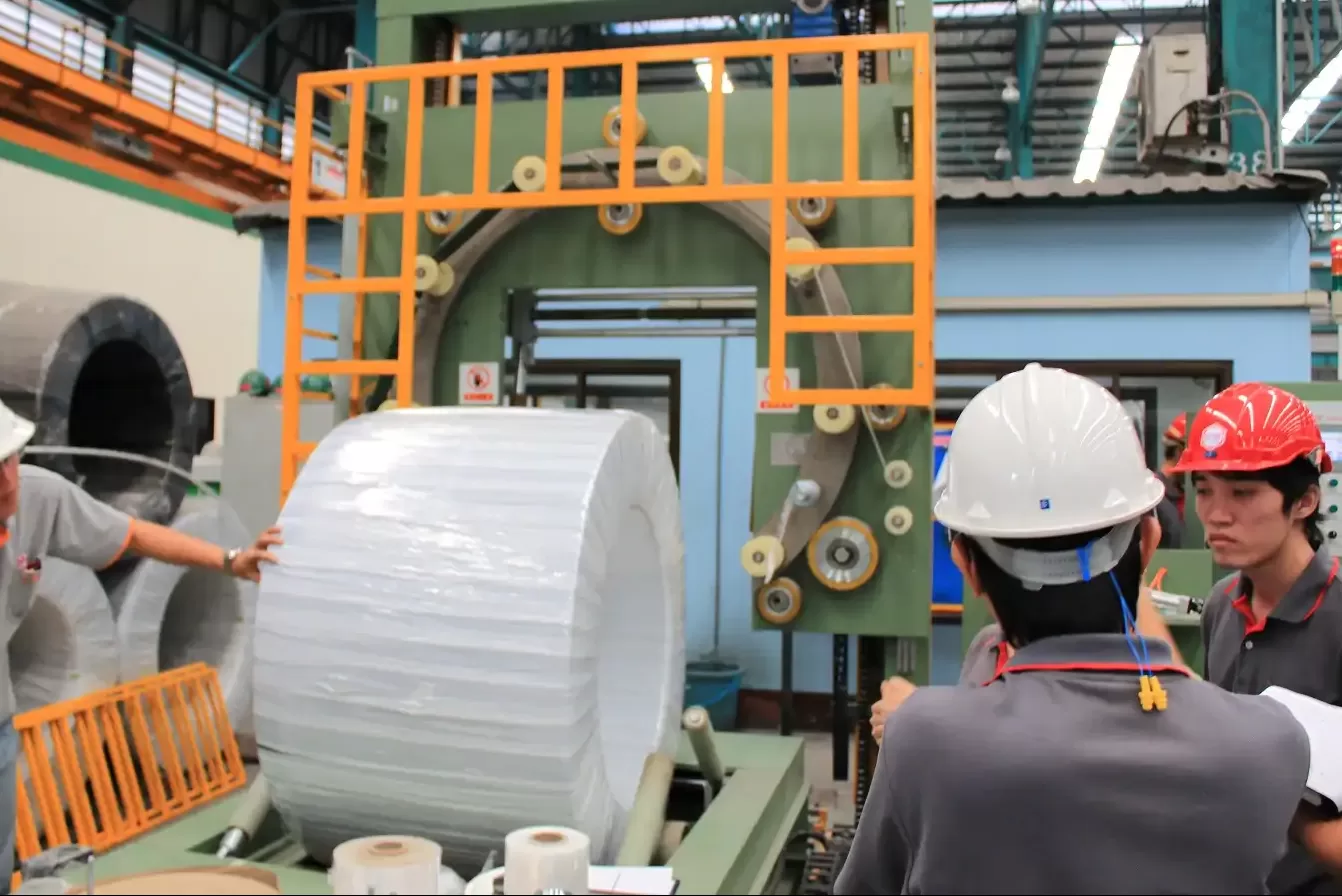

Breaking down the functionality of a coil wrapping machine gives a clearer picture of its efficiency. First, an operator places the coil onto the machine, and the process is initiated through a simple interface. The machine then automatically wraps the coil evenly, using high-quality stretch film, which not only protects the product but also aids in securing it for handling.

| Feature | Benefit |

|---|---|

| Automation | Reduces manual labor |

| Consistent Quality | Minimizes errors and damages |

| Speed and Efficiency | Increases throughput dramatically |

| Safety Enhancements | Lowers accident risks |

It’s crucial to choose a machine that aligns with your production demands and coil specifications to maximize its benefits. With over 40 years in the mechanical engineering field, I’ve witnessed the ups and downs of manual processes. The advent of coil wrapping technology has undoubtedly been a game-changer, transforming industry standards significantly.

With our expertise at FHOPEPACK, we offer a range of coil wrapping machines customized to fit diverse industrial needs. Our high-performing devices support seamless integration and unwavering reliability, marking a step forward in fully automated solutions. This is how we help clients push past traditional bottlenecks to achieve new benchmarks in operational excellence.

2. What Are the Different Types of Coil Wrapping Machines Suitable for Slitting Service Centers?

Ensuring that every steel coil remains intact from the production line to delivery is essential. This is particularly critical in slitting service centers, which handle delicate and high-value materials daily. If you seek efficiency and safety in your operation, discovering the right coil wrapping machine is vital.

Different types of coil wrapping machines can serve varied needs in slitting service centers. They include semi-automatic machines, which are best for small operations, and fully automated systems, ideal for large-scale productions. Automatic machines minimize coil handling errors and improve consistency, while semi-automated options offer flexibility and ease of use for diverse coil sizes and materials.

Diving Into Coil Wrapping Machine Types

It’s crucial to match the machine to the specific needs of your slitting service center. By dissecting the options available, you can make an informed choice that fits your operational goals. Let’s break down some primary machine types and their differences.

| Machine Type | Efficiency Level | Handling Needs |

|---|---|---|

| Semi-Automatic Wrapper | Moderate | Requires manual assistance |

| Fully Automatic Wrapper | High | Minimal manual intervention |

| Customizable Automated System | Variable | Tailored to specific needs |

-

Semi-Automatic Machines: Ideal for medium to small operations where flexibility is needed. They provide moderate efficiency and allow operators to handle coils manually as required. This type can be a good starting point for centers looking to enhance processes gradually.

-

Fully Automatic Machines: Perfect for high-throughput environments. They streamline operations by reducing manual handling and boosting overall efficiency. These machines require a higher initial investment but offer long-term cost savings.

-

Customizable Automated Systems: These are adaptable machines configured to meet precise requirements. They can handle various coil sizes and materials, providing tailored solutions that offer maximum flexibility and efficiency.

It’s important to align the machine type with your volume, budget, and specific operational needs for optimal performance.

3. What Factors Should Be Considered When Choosing a Coil Wrapping Machine?

Selecting the perfect coil wrapping machine for a slitting service center can feel daunting. With numerous features and benefits to consider, knowing where to start is essential for ensuring efficiency and reduced risk in your operations.

When choosing a coil wrapping machine, consider operational scale, material types, and budget constraints. It’s also crucial to evaluate the machine’s handling capacity and automation level. Machines must meet your production demands efficiently, ensuring minimal manual handling and enhanced quality control practices.

In-Depth Analysis of Key Selection Factors

Selecting the right machine involves a careful analysis of several core considerations. By examining these, you can ensure that your choice not only meets current needs but also prepares you for future demands.

| Consideration | Key Evaluation Point | Importance Level |

|---|---|---|

| Operational Scale | Volume of production and handling demands | Essential |

| Material Varieties | Types of coils and materials managed | High |

| Budget Allocations | Initial cost and long-term savings | Essential |

| Handling Capacity | Machine’s efficiency in reducing handling | High |

| Automation Level | Ease of integration into existing systems | Variable |

-

Operational Scale: Your machine must accommodate your current production volume. A machine too small won’t meet demands, while an overly large one could be inefficient.

-

Material Varieties: Different materials require different handling. Ensure the machine accommodates all the types you work with to maintain efficiency.

-

Budget Allocations: Analyze both initial costs and potential savings. Machines that might appear costly upfront could offer long-term savings in labor and maintenance.

-

Handling Capacity: Efficient machines reduce manual intervention, boosting productivity. Assess machines based on their efficiency improvement capabilities.

-

Automation Level: Determine how easily the machine can integrate into your existing systems. Some require significant customization, while others can seamlessly slot into current operations.

Evaluating these factors will help you make an informed decision that aligns with both immediate and future business needs.

Conclusion

In the world of slitting service centers, understanding and utilizing the right coil wrapping machine can transform operations. By investigating types and factors affecting your choice, you ensure optimal performance and efficiency. From semi-automatic to fully automated systems, selecting the right solution minimizes risks and maximizes productivity.