Steel coil packing is a crucial process in the metal industry, ensuring products are delivered in optimal condition. Standardized processes are essential to maintain coil integrity during handling, storage, and transportation, minimizing damage and waste. These processes encompass various stages, from initial preparation to final securing and documentation.

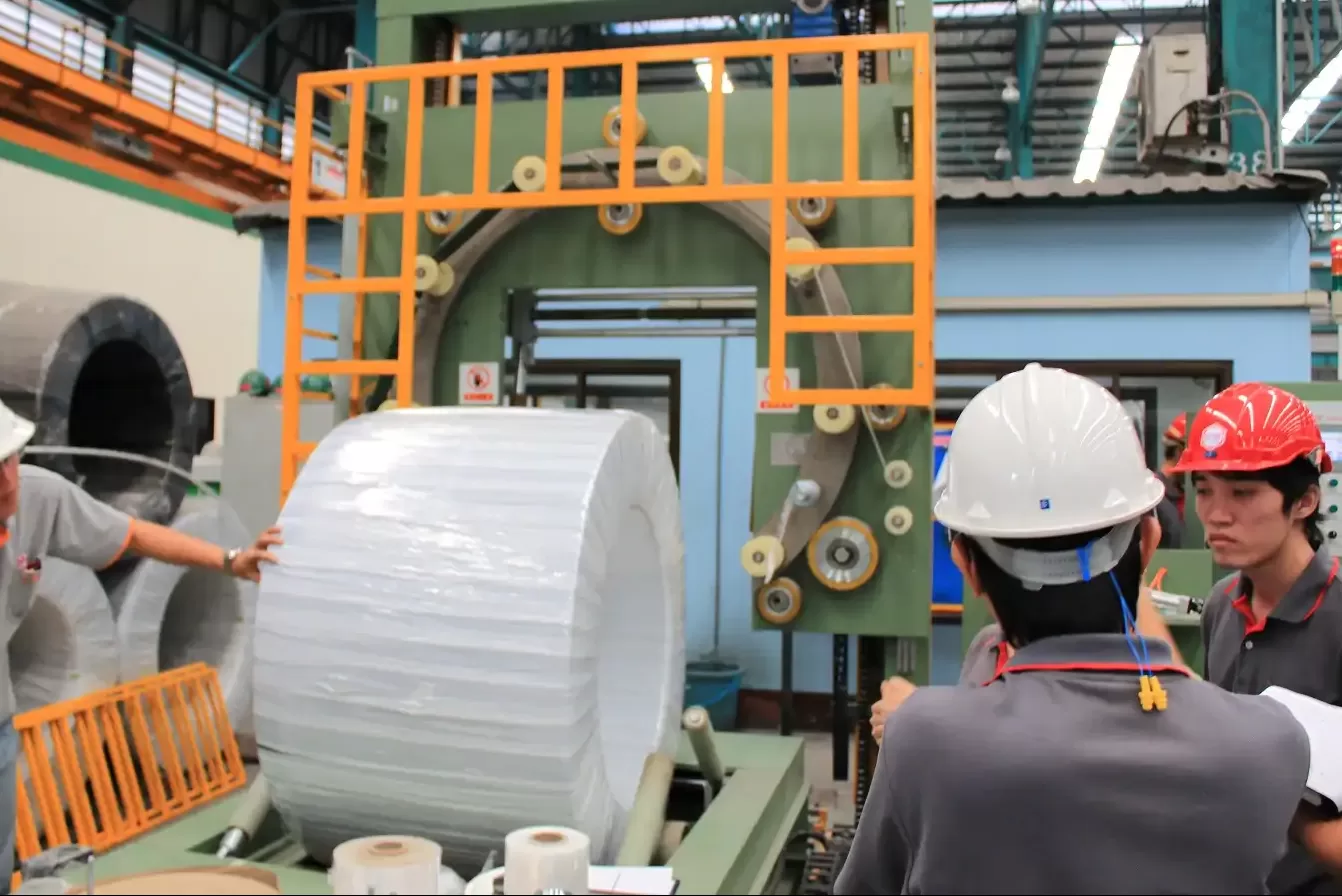

Standardized steel coil packing processes involve several key steps: preparing the coil, applying protective materials, securing the coil, and documentation. These steps are designed to ensure operational consistency and quality assurance, protecting steel coils from damage during transit and storage. Utilizing coil packing machines enhances efficiency and minimizes manual handling, further standardizing the process.

To understand the intricacies of these standardized procedures, we need to delve into each stage, exploring the machinery, materials, and quality control measures that guarantee the safe and efficient packing of steel coils. Let’s break down the core components of these processes.

2. Core Components of Standardized Steel Coil Packing

Efficient steel coil packing relies on several key components working in harmony. These components ensure that each coil is consistently and effectively prepared for its journey, safeguarding against potential damage and degradation. From machinery to materials, standardization in these components is paramount.

The core components of standardized steel coil packing include: coil wrapping machines, protective wrapping materials (like stretch film and paper), strapping systems, and robust documentation protocols. These components are integral to achieving operational consistency and maintaining quality assurance throughout the packing process, ensuring coils are securely and safely prepared for storage and transport.

To fully grasp the standardized processes, we need to dissect these core components and understand their individual yet interconnected roles. Let’s delve deeper into the machinery aspect, a cornerstone of modern coil packing efficiency.

Coil Wrapping Machinery: Automation and Precision

Coil wrapping machinery represents a significant advancement in steel coil packing. Automation offered by these machines not only accelerates the packing process but also introduces a level of precision and consistency that is difficult to achieve manually. These machines are designed to handle a variety of coil sizes and weights, making them versatile assets in any steel processing or distribution center.

Types of Coil Wrapping Machines

There are several types of coil wrapping machines, each designed for specific needs and coil dimensions. Horizontal and vertical wrapping machines are the two primary categories. Horizontal wrappers are ideal for heavier and larger diameter coils, while vertical wrappers are better suited for lighter and smaller coils. Within these categories, further specialization exists, including machines designed for specific materials or wrapping patterns.

Key Features of Coil Wrapping Machines

Modern coil wrapping machines are equipped with features that streamline and standardize the packing process:

- Automated Film Application: Machines apply stretch film or other wrapping materials with consistent tension and overlap, critical for weatherproofing and stability.

- Adjustable Settings: Operators can program machines for different coil sizes, wrapping patterns, and tension levels, ensuring flexibility and standardization across various products.

- Integrated Strapping Systems: Some advanced machines integrate strapping mechanisms, further securing the coil after wrapping.

- User-Friendly Interfaces: Modern interfaces allow for easy setup, monitoring, and adjustment of packing parameters, reducing operator error and enhancing consistency.

- Safety Features: Automated systems often include safety sensors and emergency stops, protecting personnel and preventing damage to the coils.

Benefits of Automated Coil Wrapping

The transition to automated coil wrapping machines yields numerous benefits that contribute to standardization and efficiency:

| Feature | Benefit | Impact on Standardization |

|---|---|---|

| Automation | Reduces labor costs, increases throughput | Consistent process execution |

| Precision Wrapping | Minimizes product damage, ensures security | Uniform and reliable packing |

| Versatility | Handles various coil sizes and materials | Adaptability to product range |

| Consistency | Uniform packaging for every coil | Predictable output quality |

| Reduced Material Waste | Optimized film usage, cost-effective | Resource efficiency |

| Enhanced Safety | Minimizes manual handling of heavy coils | Safer working environment |

By understanding the machinery involved, we begin to see how standardization is embedded in the coil packing process. However, machinery is only part of the equation. The materials used are equally critical in ensuring effective and standardized coil packing.

3. Material Standardization in Steel Coil Packing

The selection and standardization of packing materials are as vital as the machinery itself. The right materials guarantee protection against environmental factors, physical damage, and corrosion, all while maintaining consistency across every coil packed.

Standardized materials for steel coil packing typically include multi-layer stretch wrap film for moisture protection, reinforced edge protectors to prevent strapping damage, and moisture barrier paper or VCI films for corrosion prevention. Consistent use of these materials, applied uniformly by coil packing machines, ensures quality assurance and protects steel coils from environmental and handling risks.

Beyond the machinery, material standardization is crucial for robust steel coil packing. Let’s delve into the specifics of these materials and their standardized application.

Types of Standardized Packing Materials

Choosing the right packing material is crucial for protecting steel coils from various hazards. Standardized materials are selected based on their protective properties, cost-effectiveness, and ease of application.

Stretch Wrap Film

Stretch wrap film is a primary material, typically made of polyethylene. Its elasticity allows it to be tightly wrapped around coils, providing:

- Moisture Barrier: Prevents water ingress, reducing the risk of rust and corrosion.

- Dust and Dirt Protection: Shields coils from environmental contaminants.

- Load Stability: Compresses and secures the coil, preventing unwinding and shifting during transit.

- UV Protection: Specialized films can protect against UV degradation if coils are stored outdoors.

Standardized stretch films are often multi-layered, offering enhanced tear resistance and puncture protection.

Edge Protectors

Edge protectors, made from cardboard, plastic, or reinforced composites, are critical for preventing damage from strapping:

- Strapping Damage Prevention: Distributes strapping pressure, preventing edges from cutting into the coil.

- Impact Resistance: Provides additional cushioning at vulnerable coil edges.

- Shape Integrity: Helps maintain the coil’s shape during handling and stacking.

Standardized edge protectors come in various sizes and strengths, selected based on coil weight and strapping tension.

Moisture Barrier Paper and VCI Films

For enhanced corrosion protection, especially in humid or marine environments, moisture barrier papers and Vapor Corrosion Inhibitor (VCI) films are used:

- Moisture Absorption: Barrier paper absorbs residual moisture, further reducing rust risk.

- Corrosion Inhibition: VCI films release chemicals that create a protective atmosphere, preventing corrosion even in micro-environments.

- Direct Contact Protection: These materials can be placed directly against the steel, providing a primary defense against corrosion.

Standardized moisture barrier and VCI materials are specified based on the storage duration and environmental conditions the coils will face.

Strapping Materials

Strapping is essential for securing the wrapped coil, preventing unwinding and maintaining package integrity:

- Steel Strapping: High-tensile strength, used for heavy coils requiring maximum security.

- Polyester Strapping: Strong and flexible, a cost-effective alternative to steel for medium to heavy coils.

- Polypropylene Strapping: Lighter and more economical, suitable for lighter coils and bundling.

Standardized strapping is selected based on coil weight, handling methods, and transportation distance, with specified breaking strengths and application techniques.

By standardizing these materials and their application, businesses ensure consistent protection for their steel coils, minimizing damage and maintaining product quality throughout the supply chain. The final piece of standardized processes lies in the operational stages themselves.

4. Operational Stages of Steel Coil Packing

Standardized processes are defined by consistent operational stages. These stages, when executed uniformly, guarantee that every steel coil is packed to the same high standard, irrespective of operator or time.

The operational stages for standardized steel coil packing typically include coil preparation, wrapping application, strapping and securing, and finally, documentation and labeling. Each stage is meticulously planned and executed to maintain operational consistency and ensure quality assurance in coil packing, resulting in reliably protected steel coils ready for dispatch.

To fully appreciate the concept of standardized processes, let’s outline the typical operational stages involved in steel coil packing.

Step-by-Step Standardized Packing Stages

The standardized process can be broken down into distinct stages, each contributing to the overall quality and consistency of the coil packing.

-

Coil Preparation:

- Inspection: Coils are inspected for surface defects, rust, or damage before packing.

- Cleaning (if necessary): Coils may be cleaned to remove loose debris or contaminants, ensuring proper adhesion of wrapping materials and preventing corrosion.

- Drying: Coils must be dry before wrapping to prevent moisture entrapment and corrosion.

-

Material Application:

- Edge Protector Placement: Edge protectors are applied to the inner and outer edges of the coil to prevent damage from strapping.

- Primary Wrap Application: The coil is placed on the coil packing machine, and the primary layer of stretch film or moisture barrier paper is applied, often automatically by the coil packing machine.

- Secondary Wrap (if required): Additional layers of film or VCI materials are applied depending on the required level of protection.

-

Strapping and Securing:

- Strapping Application: Straps are applied around the wrapped coil at specified intervals and tension levels, securing the wrapping and stabilizing the coil.

- Strap Tensioning and Sealing: Straps are tensioned to the correct specification and sealed, ensuring they remain secure during transit.

- Quality Check: Strap tightness and placement are checked to ensure proper securing.

-

Documentation and Labeling:

- Label Application: Labels with coil identification, weight, dimensions, and handling instructions are applied to the packed coil.

- Packing List Generation: A packing list detailing the contents and packing specifications is generated for each coil.

- Photographic Documentation (optional): Photographs of the packed coil may be taken for record-keeping and quality assurance.

-

Handling and Storage:

- Proper Handling Procedures: Standardized procedures for handling packed coils, using forklifts or cranes, are followed to prevent damage.

- Designated Storage Areas: Packed coils are stored in designated areas, protected from the elements and excessive humidity.

By meticulously following these operational stages, businesses can implement a standardized steel coil packing process that ensures operational consistency, reduces variability, and maintains high levels of quality assurance.

Conclusion

Standardized processes for steel coil packing are fundamental to ensuring product integrity, minimizing losses, and maintaining operational efficiency within the steel industry. By standardizing machinery, materials, and operational stages, companies can achieve consistent, reliable, and high-quality packing outcomes. This not only protects the steel coils during their journey but also enhances customer satisfaction and reduces overall operational costs associated with damage and waste. Embracing standardized processes in steel coil packing is a strategic investment in quality and long-term success.