Effective supply chain cost management is crucial for businesses handling steel coils. Optimizing these costs not only enhances profitability but also ensures a competitive edge in the market. This article delves into practical strategies to minimize expenses associated with steel coil packing, focusing on efficiency and financial savings.

To optimize supply chain costs for steel coil packing, businesses should focus on efficient material use, streamlined processes, and strategic logistics management. Implementing automated coil packing solutions, optimizing packaging materials, and leveraging data-driven decisions in logistics can significantly reduce costs while maintaining product integrity and ensuring timely delivery.

This article explores key areas and actionable steps to achieve substantial financial savings and operational improvements in your steel coil packing supply chain. Let’s examine how targeted strategies can transform your cost structure and boost your bottom line.

1. Understanding the Costs in Steel Coil Packing Supply Chain

To effectively optimize supply chain costs for steel coil packing, it’s essential to first understand where these costs originate. A comprehensive overview of direct and indirect expenses provides a foundation for targeted improvements and financial savings.

Supply chain costs for steel coil packing encompass direct expenses like packaging materials and labor, and indirect costs such as warehousing and transportation. Efficient logistics management and optimized material usage are key to minimizing these costs and enhancing overall financial performance. Recognizing these components allows businesses to pinpoint areas for strategic intervention and cost reduction.

Breaking Down Steel Coil Packing Costs: A Detailed Analysis

Understanding the specific cost drivers in steel coil packing is crucial for effective optimization. By dissecting the process, we can identify areas ripe for improvement and cost reduction.

Direct Costs: Tangible Expenses in Packing

Direct costs are those immediately attributable to the packing process. These are typically easier to quantify and control.

- Packaging Materials: This includes the cost of wrapping film, steel or plastic straps, edge protectors, and any other materials used to secure and protect the steel coils. Material selection and efficient usage are critical factors.

- Labor: The wages and benefits of personnel directly involved in the packing process, including machine operators, material handlers, and quality control staff. Automation can significantly impact these costs.

- Energy Consumption: Power used by packing machinery, lighting, and heating/cooling in the packing area. Energy-efficient equipment and optimized operational schedules can reduce these expenses.

Indirect Costs: Overheads and Operational Expenses

Indirect costs are not directly tied to each coil packed but are necessary for the overall packing operation. These can be harder to track but are equally important to manage.

- Warehousing: Costs associated with storing packaging materials and packed steel coils. Efficient inventory management and just-in-time material delivery can minimize warehousing needs.

- Transportation: Expenses for moving packaging materials to the packing facility and transporting packed coils to customers or further processing locations. Optimized logistics and route planning are essential.

- Equipment Maintenance and Depreciation: Costs for maintaining packing machinery and the depreciation of this equipment over time. Regular maintenance schedules and investing in durable, reliable machinery can mitigate these costs.

- Waste and Rework: Costs incurred from damaged packaging materials, improperly packed coils requiring rework, and disposal of waste. Quality control and process optimization are vital to minimize these losses.

Total Cost of Ownership (TCO) for Packing Equipment

Considering the Total Cost of Ownership (TCO) for packing equipment provides a long-term perspective on cost management. TCO includes not just the initial purchase price but also operational costs, maintenance, and lifespan.

| Cost Component | Description | Impact on TCO |

|---|---|---|

| Initial Investment | Purchase price of the coil packing machine | High upfront cost, consider ROI and long-term benefits |

| Installation Costs | Expenses for setting up and integrating the machine into the production line | Can be significant, plan for efficient integration |

| Operational Costs | Energy consumption, labor, consumables (strapping, film) | Recurring costs, optimize for efficiency |

| Maintenance Costs | Regular servicing, repairs, spare parts | Predictable costs, preventative maintenance is key |

| Downtime Costs | Losses from production halts due to machine failure | Unpredictable but potentially high, reliability is crucial |

| Lifespan and Disposal | Useful life of the machine, disposal or upgrade costs at end-of-life | Long-term planning, consider resale value or recycling |

By analyzing both direct and indirect costs, and considering the TCO of equipment, businesses can develop a holistic strategy to optimize their steel coil packing supply chain costs effectively. This comprehensive understanding paves the way for implementing targeted cost reduction measures in subsequent stages.

2. Strategic Approaches to Reduce Steel Coil Packing Costs

Once the cost components are clearly understood, strategic approaches can be implemented to drive down expenses in steel coil packing. These strategies focus on optimizing material usage, streamlining processes, and leveraging technology for efficiency.

Reducing steel coil packing costs involves optimizing material use, implementing efficient packing processes, and leveraging technology. Strategic material selection, automation, and just-in-time inventory management are key tactics to achieve significant financial savings. By adopting these approaches, businesses can enhance their operational efficiency and reduce overall expenditure.

Implementing Cost-Effective Strategies: A Practical Guide

To effectively reduce costs in steel coil packing, businesses should consider a multi-faceted approach that addresses various aspects of the packing process.

Optimize Packaging Materials

Selecting the right packaging materials and using them efficiently is fundamental to cost reduction.

- Material Selection: Opt for cost-effective yet durable materials. Consider thinner but high-strength films and straps that provide adequate protection without excess material usage. Explore recyclable or biodegradable options to potentially reduce disposal costs and enhance sustainability.

- Reduce Material Waste: Implement measures to minimize material waste. This includes training operators on optimal material usage, regularly checking machinery for proper function to avoid material damage during packing, and recycling any unavoidable waste.

- Bulk Purchasing: Negotiate with suppliers for bulk discounts on packaging materials. Forecast material needs accurately to take advantage of volume pricing and reduce per-unit costs.

Streamline Packing Processes

Efficient packing processes reduce labor costs, energy consumption, and material waste.

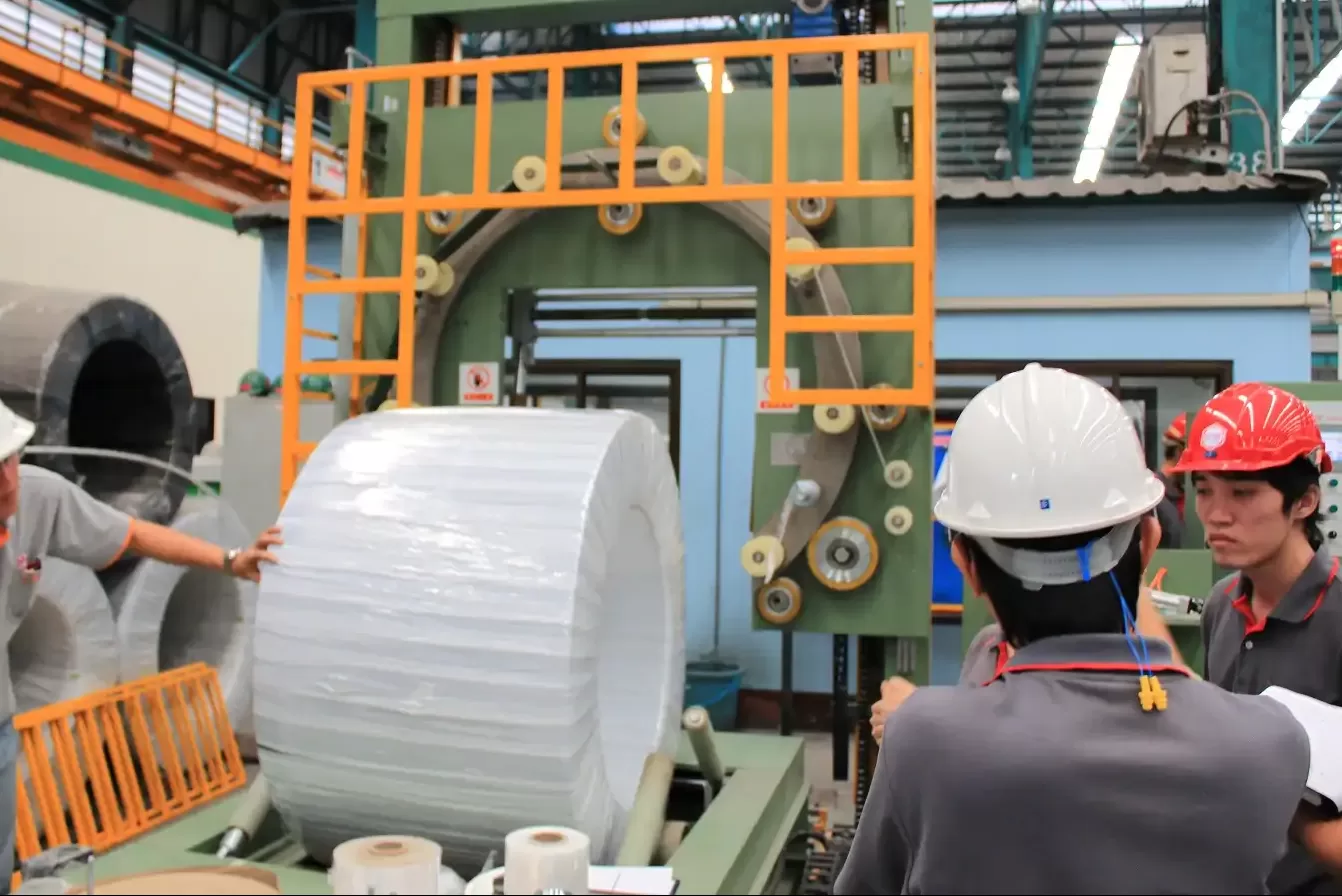

- Automation: Invest in automated coil packing machines. Automation reduces manual labor, increases packing speed, and ensures consistent packing quality, minimizing rework and material waste. Automated systems can also be programmed for optimal material usage. Coil packing machine improve efficiency.

- Standardization: Standardize packing procedures to ensure consistency and efficiency. Develop clear guidelines and training programs for operators to follow best practices. Standardized processes reduce variability and errors, leading to fewer reworks and material savings.

- Just-In-Time Material Supply: Implement a just-in-time (JIT) system for packaging materials. This reduces the need for large warehousing space and minimizes the risk of material obsolescence or damage while in storage. JIT ensures materials are available when needed without excess inventory.

Enhance Logistics and Inventory Management

Efficient logistics and inventory practices minimize transportation and warehousing costs related to packing materials and packed coils.

- Optimize Transportation Routes: Plan efficient transportation routes for both inbound packaging materials and outbound packed coils. Consolidate shipments to maximize load capacity and reduce transportation frequency, lowering fuel and freight costs.

- Strategic Warehouse Location: Locate warehouses strategically to minimize transportation distances. If possible, position material warehouses closer to the packing facility and finished goods warehouses near major transportation hubs or customer locations.

- Inventory Management Systems: Use inventory management software to track packaging material levels and packed coil inventory in real-time. This helps prevent stockouts and overstocking, optimizing warehouse space and reducing carrying costs.

By strategically implementing these approaches, businesses can achieve significant reductions in steel coil packing costs. Optimizing materials, streamlining processes, and enhancing logistics create a more efficient and financially sound supply chain operation.

3. Leveraging Technology for Cost Optimization in Coil Packing

Technology plays a pivotal role in optimizing supply chain costs, and steel coil packing is no exception. Implementing the right technological solutions can significantly enhance efficiency, reduce errors, and drive down expenses.

Technology offers powerful tools for optimizing steel coil packing costs through automation, data analytics, and improved visibility. Investing in automated machinery, implementing IoT for real-time tracking, and using data analytics for process optimization are key technological strategies for financial savings. By embracing these technologies, businesses can transform their packing operations and achieve substantial cost benefits.

Technological Solutions for Enhanced Efficiency and Savings

Adopting specific technologies can revolutionize steel coil packing operations, leading to significant cost reductions and improved performance.

Automation and Robotics

Automating packing processes reduces labor costs, increases throughput, and ensures consistent quality.

- Automated Coil Packing Machines: Investing in automated machines streamlines the entire packing process, from wrapping and strapping to labeling and palletizing. These machines operate faster and more consistently than manual labor, reducing packing time and labor costs.

- Robotic Systems: Deploying robots for tasks like material handling and coil manipulation further reduces labor needs and improves safety. Robots can handle heavy coils with precision and speed, minimizing the risk of damage and increasing operational efficiency.

- Benefits of Automation:

- Reduced labor costs

- Increased packing speed and throughput

- Improved consistency and quality of packing

- Minimized material waste through precise application

- Enhanced safety in packing operations

IoT and Real-Time Tracking

Internet of Things (IoT) devices and real-time tracking systems provide valuable data for process optimization and cost control.

- Sensor Integration: Integrate sensors into packing machinery to monitor performance metrics like material usage, energy consumption, and operational speed. Real-time data allows for immediate adjustments to optimize efficiency and identify potential issues early.

- RFID and GPS Tracking: Use RFID tags to track packaging materials and packed coils within the facility and GPS for transportation. Real-time tracking improves inventory accuracy, reduces loss, and optimizes logistics, minimizing delays and costs.

- Data Analytics Platforms: Implement platforms to analyze data collected from IoT devices and tracking systems. Data analytics provides insights into process inefficiencies, material usage patterns, and logistical bottlenecks, enabling data-driven decisions for cost reduction.

Supply Chain Management Software

Comprehensive SCM software integrates various aspects of the supply chain, providing end-to-end visibility and control.

- Inventory Management Modules: Use software modules to optimize inventory levels of packaging materials and track packed coil stock. Efficient inventory management reduces warehousing costs and minimizes the risk of obsolescence or stockouts.

- Transportation Management Systems (TMS): Implement TMS to optimize transportation planning, route selection, and shipment consolidation. TMS reduces freight costs, improves delivery times, and enhances overall logistics efficiency.

- Predictive Analytics: Leverage predictive analytics within SCM software to forecast demand for steel coils and packaging materials. Accurate forecasting enables better production planning, inventory management, and material procurement, reducing costs and improving responsiveness to market changes.

By strategically adopting these technologies, businesses can transform their steel coil packing operations into highly efficient, data-driven, and cost-optimized processes, achieving significant financial and operational benefits.

4. Sustaining Cost Savings and Continuous Improvement

Achieving initial cost reductions in steel coil packing is just the first step. Sustaining these savings and continuously improving efficiency requires ongoing effort, monitoring, and a commitment to optimization.

To ensure long-term cost optimization in steel coil packing, businesses must establish a culture of continuous improvement and regularly monitor key performance indicators (KPIs). This involves setting benchmarks, tracking progress, and adapting strategies as needed to maintain and enhance financial savings.

Maintaining Momentum: Strategies for Long-Term Cost Management

Sustaining cost savings requires a structured approach to monitoring, evaluation, and continuous improvement.

- Establish Key Performance Indicators (KPIs): Define specific, measurable, achievable, relevant, and time-bound (SMART) KPIs to track supply chain costs. Examples include:

- Cost per coil packed

- Packaging material waste percentage

- Labor hours per coil packed

- Transportation costs per shipment

- Warehouse holding costs

- Regular Performance Monitoring: Implement a system for regularly monitoring KPIs. Use dashboards and reports to track performance against benchmarks and identify any deviations or areas needing attention. Regular monitoring allows for timely intervention and prevents cost escalation.

- Periodic Audits and Reviews: Conduct periodic audits of the entire steel coil packing supply chain. Review processes, material usage, equipment performance, and logistics efficiency. Audits help identify areas for further optimization and ensure adherence to best practices.

- Feedback and Improvement Loops: Establish feedback loops with operators, logistics personnel, and suppliers. Encourage input on process improvements and cost-saving ideas. Implement a system for evaluating and acting on this feedback to drive continuous improvement.

- Embrace a Culture of Continuous Improvement: Foster a company culture that values efficiency, cost consciousness, and continuous improvement. Encourage employees at all levels to identify and suggest cost-saving opportunities. Recognize and reward contributions to cost reduction efforts to reinforce this culture.

By focusing on sustained effort and continuous improvement, businesses can ensure that initial cost savings in steel coil packing are not just temporary gains but become a permanent part of their operational efficiency and financial strategy. This ongoing commitment to optimization will drive long-term success and competitiveness.

Conclusion

Optimizing supply chain costs for steel coil packing is a multifaceted endeavor that yields significant financial and operational benefits. By understanding cost components, implementing strategic approaches, leveraging technology, and committing to continuous improvement, businesses can achieve substantial and sustainable cost reductions. Embracing these strategies not only enhances profitability but also strengthens market competitiveness and operational resilience in the steel industry.