1. How to Ensure Fire Resistance in Steel Wire Packing?

In industries where steel wire packing is crucial, ensuring fire resistance is paramount for safety and operational continuity. From construction to manufacturing, the integrity of steel wire packing in fire scenarios is a critical consideration. This article delves into the methods and standards to enhance fire resistance in steel wire packing.

To ensure fire resistance in steel wire packing, implement a multi-faceted approach. Utilize fire-resistant materials for packing itself, such as specialized coatings or wraps. Employ proper packing techniques to minimize air gaps and potential fire spread. Adhere to strict safety standards and conduct regular fire safety assessments of packing processes and storage areas. Integrating fire-resistant cables within steel wire packing adds another critical layer of protection.

As we explore the critical aspects of fire resistance in steel wire packing, understanding the nuances of fire-resistant materials, safety protocols, and the role of specialized machinery becomes essential. Let’s delve into actionable strategies and industry best practices to fortify your steel wire packing against fire hazards.

2. Understanding Fire Resistant Cables in Steel Wire Packing

Fire-resistant cables are a cornerstone of safety in environments where steel wire packing is prevalent. These cables are engineered to maintain functionality during a fire, ensuring critical systems continue to operate when needed most. Choosing the right type of fire-resistant cable is the first step in enhancing overall fire safety.

Fire-resistant cables differ significantly from flame-retardant cables. Flame-retardant cables slow fire spread, while fire-resistant cables maintain circuit integrity during fire exposure. Types include flame retardant, halogen-free low smoke (LSOH), low halogen low smoke (LSF), and true fire-resistant cables with mica tape insulation. Selecting the appropriate cable depends on the specific fire risk and operational requirements of the steel wire packing application, balancing cost and safety.

To truly understand how to ensure fire resistance, we must differentiate between cable types and delve into the standards that govern their performance. This understanding is crucial for making informed decisions that enhance safety and prevent catastrophic failures.

Delving Deeper into Fire Cable Standards

The landscape of fire-resistant cables is governed by a complex web of standards, each defining specific performance benchmarks and testing methodologies. Navigating these standards is crucial for ensuring that the selected cables and packing methods meet the required safety levels. Let’s break down some key standards and their implications.

IEC vs. UL Standards:

Two major sets of standards dominate the fire-resistant cable industry: IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories). While both aim to ensure safety, they differ in their testing approaches and geographical prevalence. IEC standards are widely accepted internationally, while UL standards are primarily used in North America.

| Standard Body | Standard Designation | Focus | Key Tests | Geographical Focus |

|---|---|---|---|---|

| IEC | IEC 60332-1 | Flame retardancy of single cables | Single cable vertical flame test | International |

| IEC | IEC 60332-3 | Flame retardancy of bundled cables | Bundled cable vertical flame test | International |

| IEC | IEC 60331 | Fire resistance – circuit integrity | Fire survival test at specified temperatures and durations | International |

| UL | UL 910 (CMP) | Plenum cables – highest fire safety | Steiner Tunnel Test, smoke density | North America |

| UL | UL 1666 (CMR) | Riser cables – commercial grade | Riser Flame Test | North America |

| UL | UL 1581 (CM/CMG) | Commercial/General Purpose Cables | Vertical Tray Flame Test | North America |

Critical Differences and Considerations:

- Flame Retardancy vs. Fire Resistance: IEC 60332 series focuses on flame retardancy (preventing fire spread), while IEC 60331 and UL fire-resistance ratings (like PH ratings in BS EN 50200) address circuit integrity during a fire. Choosing between these depends on the application’s safety priorities. For steel wire packing in critical infrastructure, fire resistance is often paramount.

- Smoke and Halogen Content: Standards like IEC 61034 (smoke density) and IEC 60754 (halogen content) address the hazards beyond flame. Low Smoke Zero Halogen (LSZH) cables are increasingly preferred for enclosed spaces due to reduced toxic fumes and smoke, improving evacuation safety.

- Performance Levels: Fire-resistance standards specify performance levels, often denoted by time (e.g., PH30, PH60, PH120 in BS EN 50200), indicating how long the cable maintains circuit integrity under fire conditions. Higher ratings offer greater safety margins but may come with increased cost.

- System vs. Component Certification: It’s vital to note that cable certifications are often component-level. BS 8519 emphasizes the importance of system-level fire performance, considering installation methods and all components, not just cables in isolation. This holistic approach is crucial for real-world fire safety.

Selecting cables and packing methods based on a thorough understanding of these standards is not merely about compliance; it’s about creating a robust fire safety strategy for steel wire packing installations. Proper specification ensures that in the event of a fire, critical circuits remain operational, facilitating safe shutdown, emergency response, and minimizing damage.

3. Flame Retardant Measures for Steel Wire Packing

Beyond fire-resistant cables, implementing specific flame retardant measures directly on the steel wire packing itself provides an additional layer of protection. These measures aim to prevent ignition, slow flame spread, and contain fires within the packing area.

Several effective flame retardant measures can be applied to steel wire packing. These include using fire retardant coatings on the packing materials, wrapping with fireproof tape, and employing blocking materials to seal gaps. Proper sealing of cable penetrations and the installation of fire barriers within packing areas are also crucial. These measures collectively minimize fire risks associated with steel wire packing.

Let’s explore the technical details and best practices for implementing these flame retardant measures effectively, ensuring comprehensive fire protection for steel wire packing.

Technical Details of Flame Retardant Coatings and Wrappings

Flame retardant coatings and wrappings are direct interventions to enhance the fire resistance of steel wire packing. These materials create a barrier, delaying ignition and slowing the spread of flames. Understanding the types of materials and application techniques is key to maximizing their effectiveness.

Types of Flame Retardant Coatings:

- Intumescent Coatings: These coatings are highly effective. Upon exposure to heat, they expand and char, creating an insulating layer that protects the underlying material. Intumescent coatings are ideal for steel wire packing because they can conform to complex shapes and provide excellent thermal insulation.

- Cementitious Coatings: These coatings are typically thicker and offer robust fire protection. They are less flexible than intumescent coatings but provide excellent fire resistance and physical protection. Cementitious coatings are suitable for areas where steel wire packing requires a more rigid and impact-resistant fire barrier.

- Ablative Coatings: Ablative coatings work by absorbing heat and releasing it through a controlled decomposition process. They are effective in long-duration fires and are often used in demanding industrial environments.

Application Techniques for Coatings:

- Spraying: Spray application is efficient for covering large areas of steel wire packing quickly and evenly. Airless sprayers are commonly used for applying thicker coatings like intumescent and cementitious types.

- Brushing and Rolling: These methods are suitable for smaller areas or for detailed applications. Brushing and rolling allow for precise control and are useful for touch-ups and intricate packing configurations.

Fireproof Tapes and Wraps:

- Mica Tape: As mentioned earlier, mica tape is crucial for fire-resistant cables themselves. It can also be used to wrap steel wire packing bundles, providing excellent electrical insulation and fire resistance. Mica tape withstands extremely high temperatures and maintains its integrity even when the surrounding materials burn away.

- Silicone Rubber Tapes: These tapes offer good flexibility and fire resistance. They are often used for wrapping cable joints and splices within steel wire packing, providing a fire-resistant seal.

- Fiberglass Tapes with Fire Retardant Coatings: These tapes combine the strength of fiberglass with flame retardant properties. They are durable and can provide mechanical protection in addition to fire resistance.

Best Practices for Coatings and Wrappings:

- Surface Preparation: Ensure the steel wire packing surface is clean, dry, and free of rust or contaminants before applying any coating or wrapping. Proper surface preparation is critical for adhesion and long-term performance.

- Correct Thickness: Apply coatings and wrappings to the manufacturer-recommended thickness. Too thin an application may compromise fire resistance, while excessive thickness can be unnecessary and costly.

- Overlap and Sealing: When using tapes and wraps, ensure adequate overlap at joints and seams to prevent fire penetration. Seal edges and terminations properly to maintain continuous fire protection.

- Compatibility: Verify that coatings and wrappings are compatible with the steel wire packing materials and cable jacketing. Incompatibility can lead to degradation of materials over time.

By carefully selecting and applying flame retardant coatings and wrappings, and adhering to best practices, you can significantly enhance the fire resistance of steel wire packing. These measures, combined with fire-resistant cables, form a comprehensive fire safety strategy.

4. Safety Standards and Testing for Fire Resistance in Steel Wire Packing

Safety standards and rigorous testing are the verification backbone of fire resistance in steel wire packing. Compliance with recognized standards ensures that materials and methods meet established safety benchmarks. Testing validates performance and provides quantifiable proof of fire resistance capabilities.

Adherence to safety standards and thorough testing are essential for verifying fire resistance in steel wire packing. Key standards include IEC 60331, UL 910, and BS 8434, each specifying test methods and performance criteria. Testing procedures involve flame exposure, temperature monitoring, and circuit integrity checks. Compliance and testing ensure that fire resistance measures are effective and reliable, providing confidence in safety systems.

Let’s delve deeper into the specific standards and testing methodologies that are critical for ensuring fire-resistant steel wire packing, highlighting the importance of certification and ongoing quality control.

Comparative Analysis of Fire Resistance Standards and Regulations

Navigating the landscape of fire resistance standards requires a comparative understanding of different regulations and their testing methodologies. While we touched on IEC and UL earlier, let’s expand to include British Standards (BS) and analyze their key features in the context of steel wire packing.

Key Fire Resistance Standards Comparison:

| Standard | Focus Area | Key Tests | Application Context | Strengths | Limitations |

|---|---|---|---|---|---|

| IEC 60331 | Circuit Integrity during Fire | Flame test at 750°C or 830°C for varying durations, impact, water spray | General fire resistance for cables | Widely recognized internationally, comprehensive testing options | Component level testing, system performance not directly addressed |

| UL 910 (CMP) | Plenum Cable Fire Safety | Steiner Tunnel Test, flame spread, smoke density | Cables in air plenums (ventilation spaces) | Stringent smoke and flame spread requirements, high safety level | Primarily North American standard, may be over-specified for some applications |

| BS 8434 | Enhanced Fire Resistance | Modified fire tests incorporating impact and water spray, realistic fire curve | Enhanced fire safety for critical life safety systems | Realistic fire scenario testing, considers mechanical and environmental stresses | Primarily UK standard, may require specific equipment for testing |

| BS EN 50200 | Fire Resistance for Data/Signal Cables | Flame test at 842°C for durations PH15, PH30, PH60, PH120 | Fire resistance for small diameter cables, data/signal circuits | Specific to data and signal cables, performance levels defined by time | May not be as stringent as BS 8434 for power cables in critical applications |

| BS 8519 | System Approach to Fire Resistance | Code of Practice for selection and installation of fire-resistant systems | Overall fire safety of installed cable systems | System-level focus, considers installation and components together | Not a product standard, guidance for system design and installation |

Implications for Steel Wire Packing:

- Choosing the Right Standard: The selection of standards depends on the application. For critical life safety systems in buildings, BS 8434 or BS 8519 (system approach) might be most relevant. For general industrial applications, IEC 60331 provides a widely accepted benchmark. UL 910 is crucial for plenum spaces where smoke control is paramount.

- Testing Beyond Standards: While standards provide a framework, consider additional testing based on specific risks. For example, if steel wire packing is exposed to vibration or chemical environments, incorporate these factors into custom testing protocols.

- Certification and Third-Party Verification: Seek third-party certification from reputable bodies to validate compliance with chosen standards. Independent certification provides assurance of product performance and quality.

- Regular Audits and Inspections: Fire resistance is not a one-time achievement. Implement regular audits and inspections to ensure that fire protection measures remain effective over time. Check coatings, wrappings, and cable installations for damage or degradation.

By understanding and applying these standards and rigorously testing materials and assemblies, you can build confidence in the fire resistance of your steel wire packing systems. This proactive approach minimizes risk and maximizes safety in fire-critical environments.

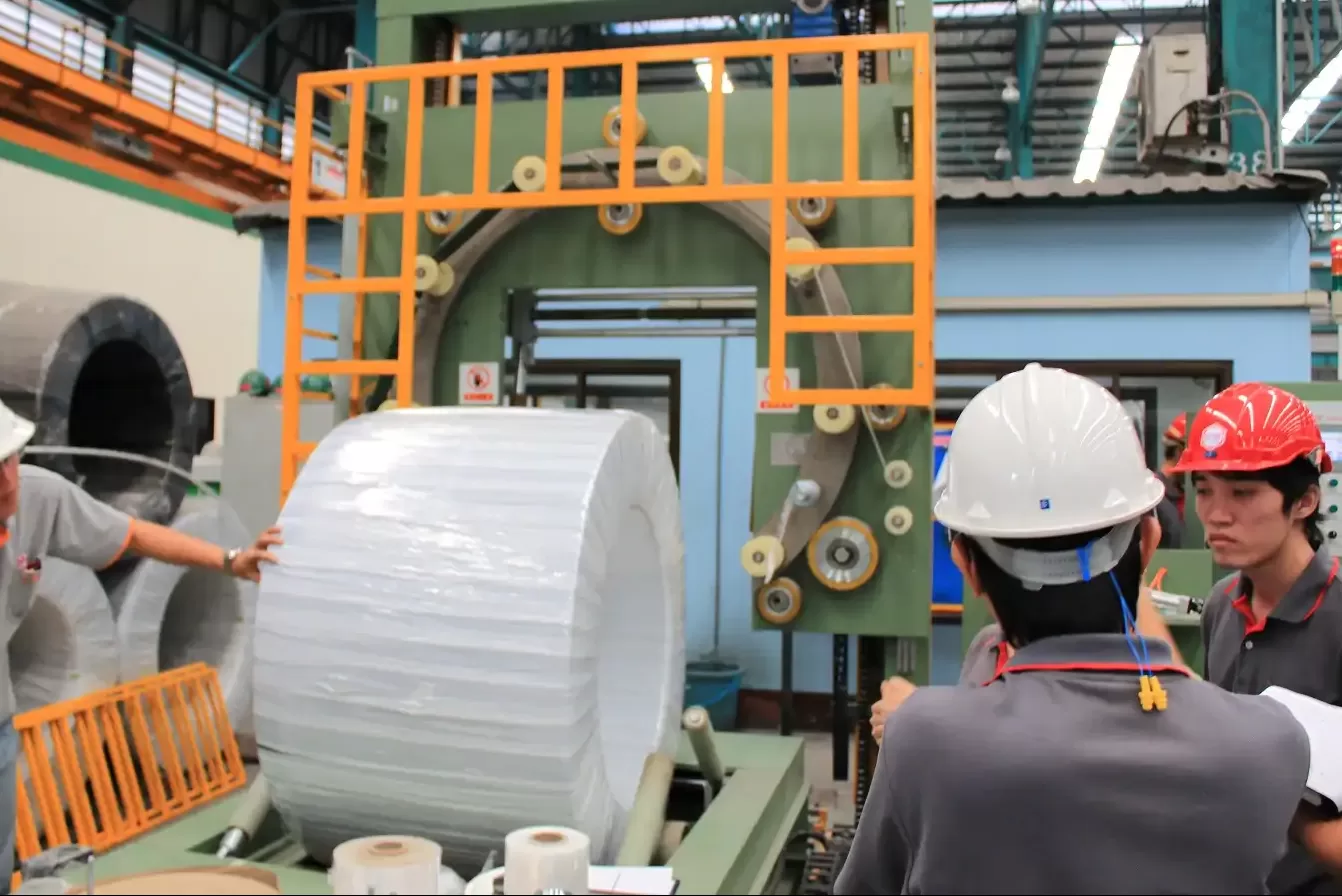

5. The Role of wire packing machine in Enhancing Safety

While seemingly indirectly related, wire packing machines play a significant role in enhancing the overall safety, including fire safety, of steel wire packing installations. Efficient and consistent packing contributes to cable integrity, reduces damage, and facilitates organized installations, all of which have positive implications for fire safety.

Wire packing machines enhance safety by ensuring consistent and secure packing of steel wires. This minimizes physical damage to cables during handling and transportation, preserving their fire-resistant properties. Organized packing also facilitates neater cable installations, reducing congestion and potential fire hazards. Automated packing processes improve efficiency and consistency, contributing to overall safety and reliability in steel wire systems.

Let’s explore in detail how the automation and precision offered by wire packing machines indirectly but effectively contribute to improved fire safety in steel wire applications.

Wire packing machines, while not directly applying fire retardant materials, contribute to fire safety in several key ways:

- Damage Prevention: Manual packing can lead to cable bending, kinking, and abrasion, potentially damaging the cable jacketing and compromising fire-resistant layers. Wire packing machines ensure gentle and controlled handling, minimizing physical stress on cables and preserving their integrity. Undamaged cables are less susceptible to electrical faults and fire initiation.

- Consistent Packing Density: Uniform packing density achieved by machines reduces air gaps within cable bundles. Air gaps can act as channels for fire propagation. Denser, machine-packed bundles are less likely to support rapid fire spread.

- Organized Cable Management: Machines facilitate neat and organized cable coiling and packing. This leads to tidier cable installations in trenches, tunnels, and buildings. Organized cable runs reduce congestion, improve airflow (preventing heat buildup), and make it easier to access and maintain cables, all contributing to reduced fire risk.

- Efficient Application of Protective Wraps: Some advanced wire packing machines can be integrated with systems that automatically apply fire retardant wraps or tapes during the packing process. This automation ensures consistent and efficient application of these crucial protective layers, enhancing fire resistance directly during packing.

- Reduced Human Error: Automated machines minimize human error in packing processes. Consistent tension, proper coiling, and accurate application of wraps are all ensured by machine precision, reducing variability and potential flaws that could compromise fire safety.

- Improved Traceability and Quality Control: Modern wire packing machines often integrate with data logging and quality control systems. This allows for tracking packing parameters, ensuring consistency, and providing records for quality audits. Traceability is crucial for verifying that fire safety standards are consistently met in every packed bundle.

In essence, wire packing machines, through their precision, consistency, and potential for automation, create a foundation for enhanced fire safety in steel wire applications. By minimizing damage, ensuring organized installations, and facilitating the application of protective measures, these machines play a vital, albeit indirect, role in fire prevention and mitigation.

Conclusion

Ensuring fire resistance in steel wire packing is a multifaceted endeavor requiring a combination of fire-resistant materials, proactive safety measures, rigorous testing, and careful attention to installation practices. From selecting appropriate fire-resistant cables and applying flame retardant coatings to adhering to stringent safety standards and leveraging the benefits of fire resistance enhancing technologies like wire packing machines, a comprehensive approach is essential. By prioritizing fire safety at every stage, industries can significantly mitigate risks, protect infrastructure, and safeguard lives and property.