How to Design an Automated Control System for Mold Upenders?

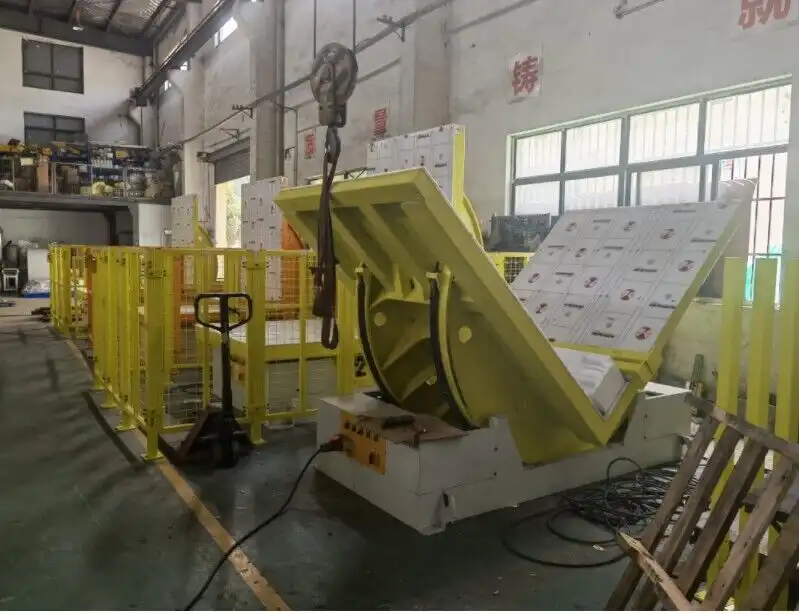

Imagine the transformation from manually wrestling heavy molds to effortlessly flipping them with automated systems. Mold upenders have revolutionized manufacturing, enhancing safety and efficiency. Designing an automated control system for these machines is key to unlocking their full potential.

Designing an automated control system for mold upenders involves integrating sensors, programmable logic controllers (PLCs), and user-friendly interfaces to ensure precise and safe mold handling. Key considerations include selecting appropriate sensors for position and load monitoring, programming PLCs for automated cycles and safety interlocks, and creating intuitive user interfaces for seamless operation and monitoring. A well-designed control system optimizes efficiency, reduces manual intervention, and enhances the overall safety of mold handling processes.

This evolution from manual to automated mold handling is not just about convenience; it’s about transforming workflows for the better. Let’s delve into the essential elements of designing these sophisticated control systems and how they are reshaping modern manufacturing.

1. Understanding the Essentials of Mold Upender Automation

Mold upenders are indispensable in industries requiring frequent mold changes or maintenance. Automating these machines enhances safety, precision, and speed, moving heavy molds with ease and control.

Mold upender automation centers around creating a system that minimizes manual intervention while maximizing safety and efficiency in tilting heavy molds. This involves integrating components like sensors to detect mold position and weight, Programmable Logic Controllers (PLCs) to manage automated tilting cycles and safety protocols, and hydraulic or electric actuators for the physical tilting action. A well-designed automated system ensures precise, repeatable movements, reduces the risk of human error, and streamlines mold handling processes, significantly boosting productivity and safety in manufacturing environments.

To fully grasp the impact of automation, we need to explore the core components and benefits that make mold upenders indispensable in modern manufacturing. Let’s break down the key aspects of their operation and design.

Deconstructing the Automated Control System for Mold Upenders

Designing an effective automated control system requires a deep understanding of the system’s components and their interplay. Let’s dissect the core elements:

1.1 Sensors: The Eyes and Ears of the System

Sensors are crucial for providing real-time feedback to the control system. They monitor various parameters, ensuring safe and precise operation. Key sensor types include:

- Position Sensors: These track the exact angular position of the mold platform during tilting. Encoders or resolvers are commonly used for their accuracy and reliability.

- Load Cells: Integrated into the upender structure, load cells measure the weight of the mold, preventing overloading and ensuring stable operation.

- Proximity Sensors: Detect the presence or absence of molds in specific zones, crucial for safety interlocks and automated cycle initiation.

- Pressure Sensors: In hydraulic systems, pressure sensors monitor hydraulic pressure, ensuring it remains within safe operating limits.

1.2 Programmable Logic Controllers (PLCs): The Brains of the Operation

PLCs are the central processing units of automated mold upenders. They execute the control logic, manage sensor inputs, and control actuators. Key PLC functions include:

- Sequencing and Logic Control: PLCs manage the automated tilting sequences, ensuring smooth and controlled movements. Logic is programmed to handle different mold sizes and tilting angles.

- Safety Interlocks: PLCs implement safety interlocks based on sensor inputs. For example, if a proximity sensor detects an obstruction, the PLC immediately stops the tilting motion.

- Data Acquisition and Monitoring: Modern PLCs can collect operational data, such as cycle times, load weights, and error logs, which can be used for performance analysis and predictive maintenance.

- Communication Interfaces: PLCs often support communication protocols like Ethernet/IP or Profinet, allowing integration with higher-level Manufacturing Execution Systems (MES) or SCADA systems.

1.3 Actuators: Providing the Muscle

Actuators are responsible for the physical tilting motion of the mold platform. Common types include:

- Hydraulic Cylinders: Hydraulics provide high force and smooth, controlled motion, ideal for heavy molds. Proportional valves allow for precise speed and position control.

- Electric Motors and Gearboxes: Electric systems offer cleaner operation and precise control, especially with servo motors and gear reducers. They are suitable for applications where hydraulic power is less desirable or for lighter molds.

1.4 User Interface (HMI): Operator Interaction

The Human-Machine Interface (HMI) allows operators to interact with the automated system. A well-designed HMI is crucial for ease of use and effective monitoring. Key HMI features include:

- Intuitive Controls: Touchscreen interfaces with clear icons and simple navigation make operation straightforward.

- Real-time Status Displays: HMIs display real-time data from sensors and the PLC, such as mold position, load weight, and system status.

- Fault Diagnostics: HMIs provide clear fault messages and diagnostic information, speeding up troubleshooting and reducing downtime.

- Customizable Programs: Advanced HMIs allow operators to create and store custom tilting programs for different mold types and operational needs.

By carefully integrating these components, we can create a robust and efficient automated control system for mold upenders. The table below summarizes the key features and benefits of automation in mold upenders:

| Feature | Benefit |

|---|---|

| Safety Automation | Reduced workplace accidents and injuries |

| Precision Control | Minimized mold damage and repair costs |

| Efficient Operation | Increased throughput and reduced downtime |

| Labor Savings | Lower operational expenses |

| Workflow Integration | Streamlined production processes |

| Data Monitoring | Performance analysis, predictive maintenance |

| Customization | Adaptability to various mold types and operational needs |

2. Step-by-Step Guide to Designing Your Control System

Designing an automated control system for mold upenders is a multi-faceted process. A systematic approach ensures all critical aspects are considered, leading to a reliable and efficient system.

Designing an automated control system for mold upenders requires a structured approach, starting with defining operational requirements and selecting appropriate components. Key steps include: specifying mold weight and dimensions, choosing suitable sensors for position and load feedback, programming a PLC for automated cycles and safety interlocks, integrating hydraulic or electric actuators, and designing a user-friendly HMI for operation and monitoring. Thorough planning and component selection are crucial for creating a control system that maximizes safety, precision, and efficiency in mold handling.

Let’s break down the design process into actionable steps to guide you through creating your automated control system.

A Phased Approach to Control System Design

A phased approach ensures a well-structured and successful control system design. Here’s a step-by-step guide:

2.1 Define Operational Requirements

Clearly define the specific needs of your application. This includes:

- Mold Specifications: Determine the range of mold sizes, weights, and shapes the upender will handle. Consider the heaviest and most awkward molds.

- Tilting Angles: Specify the required tilting angles (e.g., 90°, 180°). Will partial tilting be necessary?

- Cycle Time Requirements: Define the desired speed and throughput for mold handling. How quickly do mold changeovers need to be?

- Safety Standards: Identify relevant safety standards and regulations that the system must comply with (e.g., ANSI B11, ISO 13849).

- Integration Requirements: How will the upender be integrated into the overall manufacturing workflow? Will it need to communicate with other systems?

2.2 Select Control System Components

Based on the operational requirements, choose appropriate components:

- PLC Selection: Select a PLC with sufficient processing power, I/O capacity, and communication interfaces. Consider factors like scan time, memory, and programming language.

- Sensor Selection: Choose sensors that meet the accuracy, reliability, and environmental requirements of the application. Consider redundancy for critical sensors.

- Actuator Selection: Decide between hydraulic or electric actuators based on load requirements, speed, precision needs, and environmental factors. Size actuators appropriately for the maximum mold weight and desired tilting speed.

- HMI Selection: Select an HMI with the required display size, resolution, touch interface, and communication capabilities. Ensure it is user-friendly and robust enough for the industrial environment.

2.3 Design the Control Logic and Safety System

Develop the control logic in the PLC program, including:

- Automated Tilting Sequences: Program the PLC to execute smooth and controlled tilting cycles. Include features like soft start and stop to minimize mold stress.

- Safety Interlocks: Implement comprehensive safety interlocks using sensor inputs. Examples include:

- Emergency stop circuits with redundant pushbuttons.

- Light curtains or laser scanners to prevent access to hazardous areas during operation.

- Overload protection based on load cell readings.

- Position limits to prevent over-travel.

- Error Handling and Diagnostics: Program the PLC to detect and handle errors gracefully. Provide clear diagnostic messages on the HMI to aid troubleshooting.

2.4 Integrate and Test the System

Integrate all components and thoroughly test the entire system:

- Wiring and Installation: Ensure proper wiring and installation of all components according to electrical standards and best practices.

- Software Development and Programming: Develop and thoroughly test the PLC program and HMI application. Use simulation tools to verify logic and safety functions before physical commissioning.

- Commissioning and Calibration: Commission the system and calibrate sensors and actuators. Test all safety functions rigorously.

- Performance Testing: Conduct performance tests to verify that the system meets cycle time, accuracy, and reliability requirements. Test with a range of mold sizes and weights.

By following these steps, you can systematically design and implement an automated control system that enhances the performance and safety of your mold upender operations.

3. Advanced Features for Enhanced Control and Efficiency

Modern automated control systems for mold upenders go beyond basic tilting functions. Advanced features can significantly enhance control, efficiency, and integration capabilities.

Advanced control systems for mold upenders incorporate features like variable speed control, remote operation, and data logging to optimize performance and usability. Variable speed control allows for adjusting tilting speed based on mold sensitivity and weight, while remote operation enhances safety and operator convenience. Data logging and analytics provide valuable insights into system performance, enabling predictive maintenance and process optimization. These advanced features contribute to increased precision, reduced cycle times, and improved overall equipment effectiveness (OEE) in mold handling operations.

Let’s explore some of these advanced features and how they can elevate your mold upender control system.

Elevating Control Systems with Cutting-Edge Features

Incorporating advanced features can transform a standard automated control system into a highly efficient and intelligent mold handling solution.

3.1 Variable Speed Control

Adjusting the tilting speed is crucial for handling different mold types and weights. Variable speed control offers several advantages:

- Optimized Cycle Times: Faster tilting speeds for lighter molds and slower speeds for heavier or delicate molds optimize cycle times without compromising safety.

- Reduced Mold Stress: Slower, smoother movements minimize stress on molds, especially during start and stop phases, reducing the risk of damage.

- Improved Operator Control: Operators can fine-tune the speed based on visual feedback and specific task requirements.

Variable speed control is typically achieved using:

- Variable Frequency Drives (VFDs) for Electric Motors: VFDs precisely control the speed of AC motors by varying the frequency and voltage supplied.

- Proportional Valves for Hydraulic Systems: Proportional valves allow for precise control of hydraulic flow, enabling variable speed control of hydraulic cylinders.

3.2 Remote Operation and Monitoring

Remote operation enhances safety and operator convenience, especially in hazardous environments or when the operator needs to be at a distance for better visibility. Remote capabilities include:

- Pendant Controls: Wired pendant controls provide a portable and ergonomic interface for operators to control the upender from a safe distance.

- Wireless Remote Controls: Wireless remotes offer greater freedom of movement and can be particularly useful for large molds or complex setups.

- Remote Monitoring via Network: Integrating the control system with a plant network allows for remote monitoring of system status, performance data, and alarms from a central control room.

3.3 Data Logging and Analytics

Modern control systems can log operational data for analysis and performance optimization. Data logging and analytics enable:

- Performance Tracking: Monitor key performance indicators (KPIs) such as cycle times, uptime, and error rates to identify areas for improvement.

- Predictive Maintenance: Analyze data patterns to predict potential failures and schedule maintenance proactively, minimizing downtime.

- Process Optimization: Identify bottlenecks and inefficiencies in the mold handling process through data analysis, leading to optimized workflows and increased throughput.

Data logging systems typically store data in databases or cloud platforms, allowing for advanced analytics and reporting using tools like:

- SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems provide real-time monitoring, data logging, and visualization capabilities.

- Cloud-Based IoT Platforms: IoT platforms offer scalable data storage, analytics, and remote access capabilities, enabling advanced features like predictive maintenance and remote diagnostics.

By incorporating these advanced features, you can build a mold upender control system that is not only automated but also intelligent, adaptable, and future-proof.

| Feature | Description | Expected Impact |

|---|---|---|

| Variable Speed Control | Adjustable tilting speeds based on mold type and weight | Optimized cycle times, reduced mold stress, improved operator control |

| Remote Operation | Pendant or wireless controls, remote monitoring via network | Enhanced safety, operator convenience, improved visibility, centralized monitoring |

| Data Logging & Analytics | Real-time data monitoring, predictive analytics | Optimized performance, predictive maintenance, reduced downtime, process improvement |

4. Key Considerations for Safety in Automated Systems

Safety is paramount when designing automated control systems for heavy machinery like mold upenders. A robust safety system is not just a regulatory requirement but also crucial for protecting personnel and equipment.

Safety in automated mold upender systems is achieved through redundant safety circuits, emergency stop mechanisms, and safeguarding measures like light curtains and pressure sensors. Emergency stop buttons should be readily accessible, and safety circuits must be designed to immediately halt operation upon detecting hazards. Light curtains and laser scanners create safety zones, preventing operation if personnel enter hazardous areas, while pressure sensors monitor hydraulic systems for safe pressure levels. These measures collectively ensure a safe operating environment, minimizing risks associated with heavy mold handling.

Designing for safety requires a multi-layered approach, incorporating both hardware and software safety features. Let’s explore key safety considerations for automated mold upender control systems.

Building a Multi-Layered Safety System

A comprehensive safety system incorporates multiple layers of protection, addressing various potential hazards. Key elements include:

-

Emergency Stop (E-Stop) System:

- Redundant E-Stop Buttons: Strategically placed E-stop buttons around the upender allow for immediate shutdown in emergencies. Buttons should be easily accessible and clearly marked.

- Hardwired Safety Relays: E-stop circuits should be hardwired using safety relays that are certified to meet relevant safety standards (e.g., ISO 13850). Redundant relays provide backup in case of component failure.

- Fail-Safe Design: The E-stop system must be fail-safe, meaning that in case of a component failure, the system defaults to a safe state (i.e., power is removed from actuators, and motion stops).

-

Safety Interlocks and Sensors:

- Light Curtains and Laser Scanners: These devices create safety zones around the upender. If an operator or object breaks the light beam or enters the scanned area, the system immediately stops.

- Safety-Rated Proximity Sensors: Used to detect the presence of molds in loading/unloading zones and to verify that safety gates or barriers are in place before operation can commence.

- Pressure Sensors in Hydraulic Systems: Monitor hydraulic pressure to ensure it remains within safe limits. Overpressure or pressure loss can indicate malfunctions and trigger safety shutdowns.

- Load Cell Overload Protection: Load cells continuously monitor the weight of the mold. If the weight exceeds the safe operating limit, the system prevents tilting and issues a warning.

-

Software Safety Functions:

- Safety PLC Programming: Safety PLCs and safety-rated programming languages (e.g., IEC 61131-3 Safety) are used to implement safety logic. Safety functions must be rigorously validated and verified.

- Motion Monitoring: Safety software can monitor actuator position, speed, and acceleration to ensure they remain within safe limits. Overspeed or over-acceleration can trigger safety stops.

- Safe Torque Off (STO): In electric servo systems, STO functionality can be used to safely disable motor torque without removing power from the drive, allowing for quick and safe stops.

-

Physical Safeguarding:

- Safety Barriers and Fencing: Physical barriers prevent unauthorized access to the upender’s working area. Interlocked gates ensure that the system cannot operate when gates are open.

- Warning Signage and Labels: Clear warning signs and labels indicate potential hazards and safety procedures.

By integrating these safety measures into your automated control system design, you can significantly reduce the risk of accidents and create a safer working environment for operators around mold upenders.

Conclusion

The journey from manual mold handling to sophisticated automated systems marks a significant leap in manufacturing efficiency and safety. Designing an automated control system for mold upenders is a critical undertaking, requiring careful consideration of components, control logic, and safety protocols. By embracing a systematic design approach and incorporating advanced features, manufacturers can unlock the full potential of mold upenders, streamlining workflows, reducing labor costs, and most importantly, creating a safer and more productive working environment. As technology continues to evolve, the future of mold upender automation promises even more intelligent and integrated solutions, further revolutionizing heavy material handling in modern industries.