Mold testing requires precision. Inspectors often use mold upenders to safely position molds for thorough examination, identifying potential defects and ensuring quality standards are met efficiently.

1. What is a Mold Upender and How is it Used in Mold Testing?

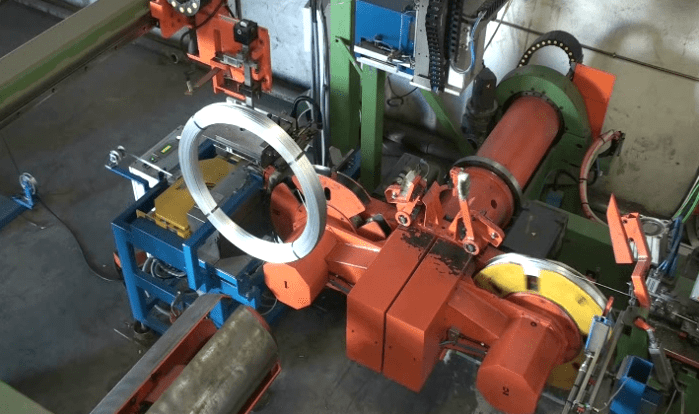

Mold upenders are specialized machines designed to safely rotate heavy molds. They help inspectors by positioning the mold for evaluation, ensuring even the most hidden areas are checked for defects.

Understanding Mold Upender Applications

In the world of packaging and mold testing, efficiency and safety are top priorities. Having spent several decades in the field, I’ve seen firsthand how tools like mold upenders truly revolutionize processes. These machines are vital in handling heavy molds, which can weigh hundreds of kilograms. They rotate these molds with precision, enabling inspectors to have a clear and thorough view of the mold from all angles.

Mold upenders are not just about moving molds; they provide stability and control, minimizing the risk of damage during inspection. This equipment is engineered with safety mechanisms that are crucial in industrial settings. With a well-designed mold upender, an inspector can evaluate a mold for defects, cracks, and irregularities more effectively.

Moreover, integrating mold upenders into the inspection process streamlines workflow and reduces manual handling demands, preventing occupational injuries. This technological advancement is a game-changer for many industries, including automotive and construction, where quality and precision are paramount. By utilizing a mold upender, companies ensure that each mold meets their stringent quality guidelines, translating into a more reliable end product. This deep dive showcases the immense potential for improving efficiency and safety with the right equipment in place.

2. What Are the Step-by-Step Procedures for Testing Mold with a Mold Upender?

Harness the full potential of a mold upender with an easy-to-follow guide that ensures safe and effective mold testing.

Mold upenders transform heavy mold testing, offering efficiency and safety. Follow these steps: position mold securely, initiate upending, inspect, and return safely. This enhances efficiency and reduces manual handling risks.

Effective Mold Testing with a Mold Upender:

I still remember my early days in packaging manufacturing. We often struggled with heavy molds, and testing them without advanced tools was daunting. Mold upenders turn mold testing into a safer, more efficient process. Here’s a breakdown of the key steps and the benefits of each:

-

Secure Positioning:

Before engaging the mold upender, ensure that the mold is properly positioned and locked in place. This step is crucial to prevent any unintended movement, which could lead to accidents or damage. Locking mechanisms and security fixtures are inspected to ensure stability. -

Upending Initiation:

With everything secured, activate the mold upender. Control panels facilitate seamless operation with minimal effort. The machinery, fine-tuned to handle massive weights, ensures a smooth transition, reducing the physical strain on workers. -

Visual and Structural Inspection:

Once in position, perform a thorough visual and structural inspection of the mold. Mold upenders elevate molds to an optimal height, facilitating an exhaustive examination. This process identifies defects or wear that might be missed during standard checks. -

Return to Initial Position:

After inspection, safely return the mold to its original position. This final step ensures that the mold is ready for further use or storage. Advanced upenders provide controlled movements, minimizing impact and prolonging mold life.

| Step | Purpose | Outcome |

|---|---|---|

| Secure Positioning | Prevent accidents and ensure stability | Safe operations |

| Upending Initiation | Facilitate smooth and efficient testing | Reduced worker strain |

| Inspection | Identify defects | Improved quality checks |

| Return to Position | Prepare mold for storage or reuse | Extended mold lifespan |

By following these step-by-step procedures, you ensure better safety and efficiency in testing molds, indicating a clear evolution from past methods.

3. What Challenges Might Inspectors Face When Using Mold Upenders?

Facing challenges with mold upenders? Identifying these hurdles ensures efficient and safe operation, enhancing testing processes.

Inspectors navigating mold upenders often encounter challenges like mechanical failures, misalignments, and user errors. Regular training, inspections, and maintenance are vital for overcoming these hurdles effectively.

Overcoming Mold Upender Challenges:

Not too long ago, I was involved in a project where mold upenders significantly transformed our workflow efficiency but also introduced new challenges. Understanding these barriers helps in mitigating their impact.

-

Mechanical Failures:

Every machinery has its mechanical limits. Mold upenders, when not regularly serviced, may face operational breakdowns. Regular inspections and timely maintenance are crucial to avoid unexpected downtimes. This also includes checking hydraulic systems and lubrication levels. -

Misalignments:

Inadequate calibration can cause molds not to align properly when upended. This poses a challenge during inspections, potentially causing damage. Operators should ensure proper alignment tools are used and regularly calibrated. -

User Errors:

Despite automated features, user errors remain a challenge. Operators may skip steps or handle controls improperly. Continuous training sessions and refresher courses help mitigate these issues, ensuring operators are well-versed in upender functionalities.

| Challenge | Cause | Mitigation Strategy |

|---|---|---|

| Mechanical Failures | Lack of regular maintenance and inspections | Scheduled maintenance checks |

| Misalignments | Faulty calibration | Regular recalibration and checks |

| User Errors | Inadequate training | Ongoing training and education |

Employing these strategies guarantees the smooth operation of mold upenders, overcoming challenges while ensuring operational efficiency.

Conclusion

Mold upenders play a pivotal role in testing and inspection by mitigating manual handling risks. They enhance safety and efficiency across industries reliant on mold testing, ensuring thorough inspections and better product quality. Regular maintenance and training are vital for unlocking these benefits, reaffirming their value in modern industrial processes.

Summarize the importance of mold upenders in testing and inspection processes and the implications for safety in various industries.