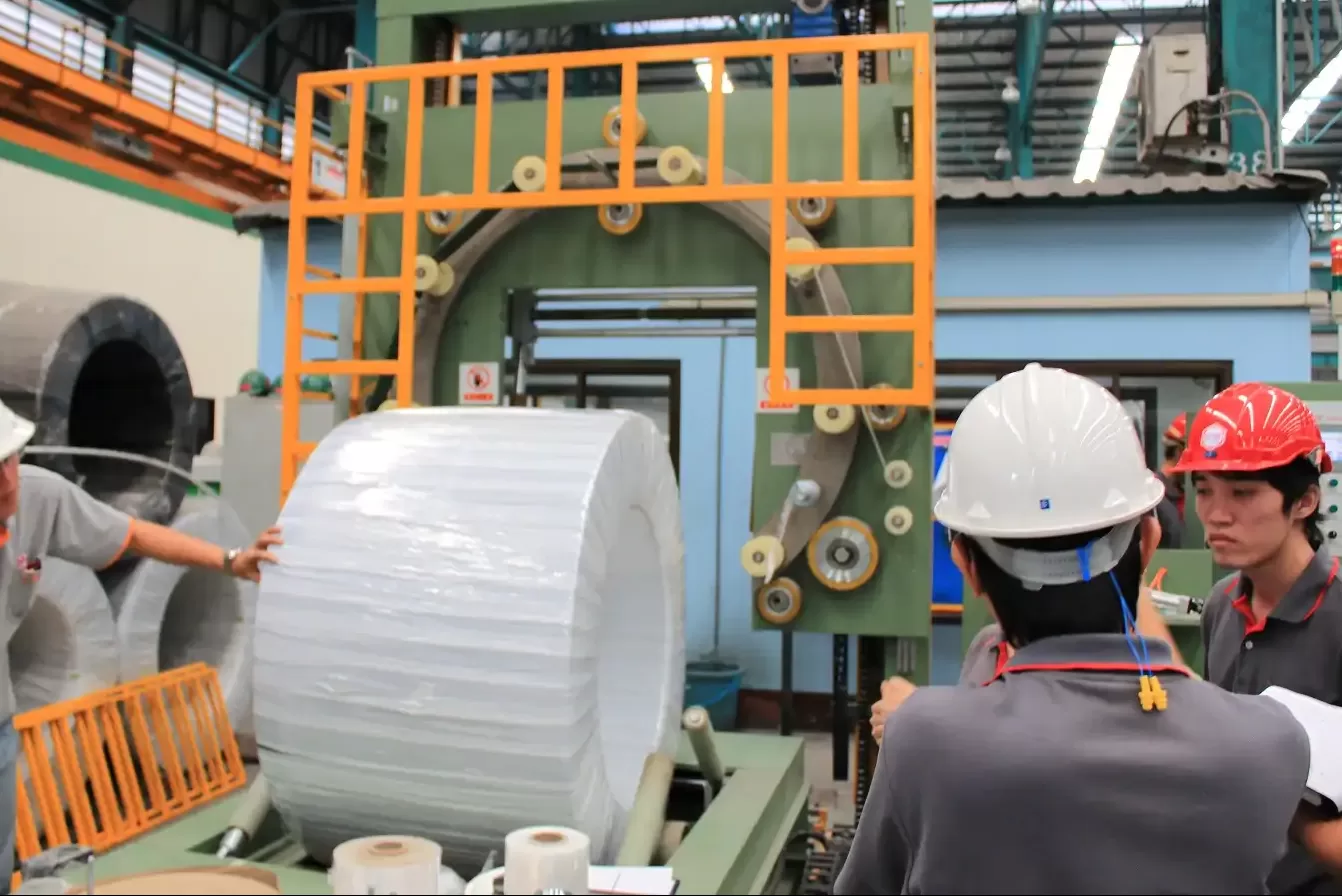

Ensuring the safe and hygienic transportation and storage of stainless steel coils intended for food contact applications is paramount. Our food-grade stainless steel coil wrapping solutions, including specialized packaging and wrapping machines, guarantee purity and compliance.

The food and beverage industry demands the highest standards of hygiene and safety, extending to every aspect of production and packaging. Stainless steel, prized for its corrosion resistance and durability, is a common material in food processing equipment and storage solutions. However, even stainless steel requires protection during transport and storage to prevent contamination and maintain its food-grade quality. This article explores the crucial role of food-grade stainless steel coil wrapping solutions, covering materials, methods, and machinery designed to ensure the integrity of stainless steel destined for food contact applications.

The Importance of Food-Grade Wrapping

Stainless steel coils used in food processing equipment, storage tanks, and other applications must be free from contaminants to prevent compromising the safety and quality of food products. Improper handling and packaging can introduce foreign substances, leading to potential health risks, product spoilage, and regulatory violations. Food-grade wrapping solutions are specifically designed to address these concerns by providing a protective barrier against environmental factors such as:

- Moisture: Leading to corrosion, even in stainless steel.

- Dust and Debris: Introducing potential contaminants.

- Physical Damage: Scratches and dents can create crevices for bacteria to grow.

- Chemical Exposure: Contact with incompatible materials can compromise the stainless steel’s integrity.

Key Components of Food-Grade Stainless Steel Coil Wrapping Solutions

A comprehensive food-grade stainless steel coil wrapping solution typically involves several key components:

- Food-Safe Packaging Materials:

- Polyethylene (PE) Film: PE film is a common choice due to its flexibility, water resistance, and food-grade certification. It provides a primary layer of protection against moisture and dust.

- Food-Safe Packaging Materials:

- Polypropylene (PP) Film: PP film offers higher tensile strength and temperature resistance than PE film, making it suitable for demanding applications.

- Waterproof Kraft Paper: Kraft paper provides an additional barrier against moisture and physical damage. When coated or laminated with food-grade materials, it enhances protection and durability.

- Shrink Wrap: Shrink wrapping conforms tightly to the coil’s shape, providing a secure and tamper-evident seal.

- Hygienic Wrapping Machines:

- Automatic Coil Wrapping Machines: These machines automate the wrapping process, ensuring consistent and efficient application of packaging materials while minimizing human contact and potential contamination.

- Stainless Steel Construction: Machines used in food-grade environments should be constructed from stainless steel to prevent corrosion and facilitate easy cleaning.

- Adjustable Tension Control: The tension control allows for precise wrapping, preventing damage to the coil and ensuring a secure seal.

- Clean-in-Place (CIP) Systems: CIP systems enable thorough cleaning and sanitization of the machine without disassembly, maintaining a hygienic environment.

- Edge Protection and Support:

- Edge Protectors: Plastic or cardboard edge protectors prevent damage to the coil’s edges during handling and transportation.

- Spacers: Spacers maintain separation between coils, preventing scratching and abrasion.

- Cores: Cores provide internal support to the coil, preventing deformation and collapse.

- Securement Methods:

- Strapping: Polypropylene or polyester strapping secures the wrapped coil, preventing it from unravelling during transit.

- Banding: Steel or plastic banding provides a high-strength method for securing heavy coils.

- Skids and Crates: Skids and crates offer a stable platform for transportation and storage, protecting the coil from impact and vibration.

Types of Food-Grade Wrapping Techniques

Several wrapping techniques can be employed to protect stainless steel coils, each offering different levels of protection and suitability for specific applications:

- Spiral Wrapping: Film is wrapped around the coil in a spiral pattern, providing a basic level of protection against dust and moisture.

- Full Wrapping: The coil is completely enclosed in film, offering enhanced protection against environmental factors.

- Shrink Wrapping: Heat is applied to shrink the film tightly around the coil, creating a secure and tamper-evident seal.

-

Vacuum Sealing: Air is evacuated from the packaging before sealing, providing superior protection against oxidation and corrosion.

Here’s a comparison of different stainless steel coil wrapping techniques, focusing on their level of protection, applications and cost:Wrapping Technique Level of Protection Suitable Applications Cost Spiral Wrapping Basic Protection against dust and minor scratches, internal transportation. Low

| Full Wrapping | Medium | Enhanced protection against dust, moisture, and light impacts, long-distance transporting. | Medium |

| Shrink Wrapping | High | Secure, tamper-evident protection against environmental elements, suitable for retail or stringent compliance scenarios. | Medium-High|

| Vacuum Sealing | Superior | Protection against oxidation, corrosion, and all environmental factors. | High |

Stainless Steel Material and Cleanliness Standards

The type of stainless steel also plays a vital role in food-grade applications. Common grades include 304 and 316, both known for their corrosion resistance. However, 316 stainless steel contains molybdenum, further enhancing its resistance to chloride corrosion, making it ideal for harsher environments. Regardless of the grade, the stainless steel must be thoroughly cleaned and passivated before wrapping to remove any surface contaminants and maximize corrosion resistance.

Regulatory Compliance

Food-grade packaging materials and processes must comply with relevant regulations, such as those set forth by the U.S. Food and Drug Administration (FDA) and the European Union (EU). These regulations specify the types of materials that are safe for food contact and the manufacturing practices required to maintain hygiene and prevent contamination.

FDA Regulations:

- FDA CFR 21 177.1520: Focuses on safe usage of olefin polymers meeting specific extraction and usage criteria. This is relevant because polyethylene (PE) and polypropylene (PP) used in wrapping stainless steel coils intended for food contact equipment must meet these standards to ensure they do not contaminate the food or its manufacturing process.

- FDA CFR 21 175.300: Covers resinous and polymeric coatings with permitted components like zinc-containing substances and epoxy resins. It stipulates permissible coating application, including food types and conditions.

Considerations for International Shipments

International shipments require extra attention to packaging and securement. Coils must be protected against the rigors of ocean transport, including exposure to saltwater, humidity, and vibration. Crates should be constructed from durable materials and designed to withstand stacking and handling by forklifts and cranes. Securing the coil within the crate is paramount to prevent shifting and damage during transit.

Case Studies: Successful Food-Grade Stainless Steel Coil Wrapping

Several companies have successfully implemented food-grade stainless steel coil wrapping solutions to ensure the safety and integrity of their products:

- A leading food processing equipment manufacturer: Implemented an automated wrapping system with PE film and stainless steel strapping, reducing contamination and improving product quality.

- A major stainless steel supplier: Adopted shrink wrapping with edge protection and secure skidding, minimizing damage during transportation and enhancing customer satisfaction.

- A global beverage producer: Utilizes vacuum sealing for stainless steel coils used in their bottling lines, preventing corrosion and ensuring the purity of their products.

Future Trends in Food-Grade Wrapping

The future of food-grade wrapping is likely to be shaped by several trends:

- Sustainable Materials: Increased use of biodegradable and compostable packaging materials.

- Smart Packaging: Integration of sensors to monitor temperature, humidity, and other parameters.

- Traceability: Implementation of tracking technologies to trace the origin and history of packaging materials.

- Automation: Greater automation of wrapping processes to improve efficiency and reduce human contact.

Food-grade stainless steel coils require meticulous packing and loading to prevent damage and contamination. Waterproof packaging, including waterproof kraft paper, plastic film, and secure iron rings around the edges, can be crucial for safe transport, especially in humid and marine environments. Investing in food-grade stainless steel coil wrapping solutions is a critical step in ensuring the safety and quality of food products. By selecting the right materials, equipment, and techniques, companies can protect their stainless steel coils from contamination and damage, maintain regulatory compliance, and safeguard their brand reputation.