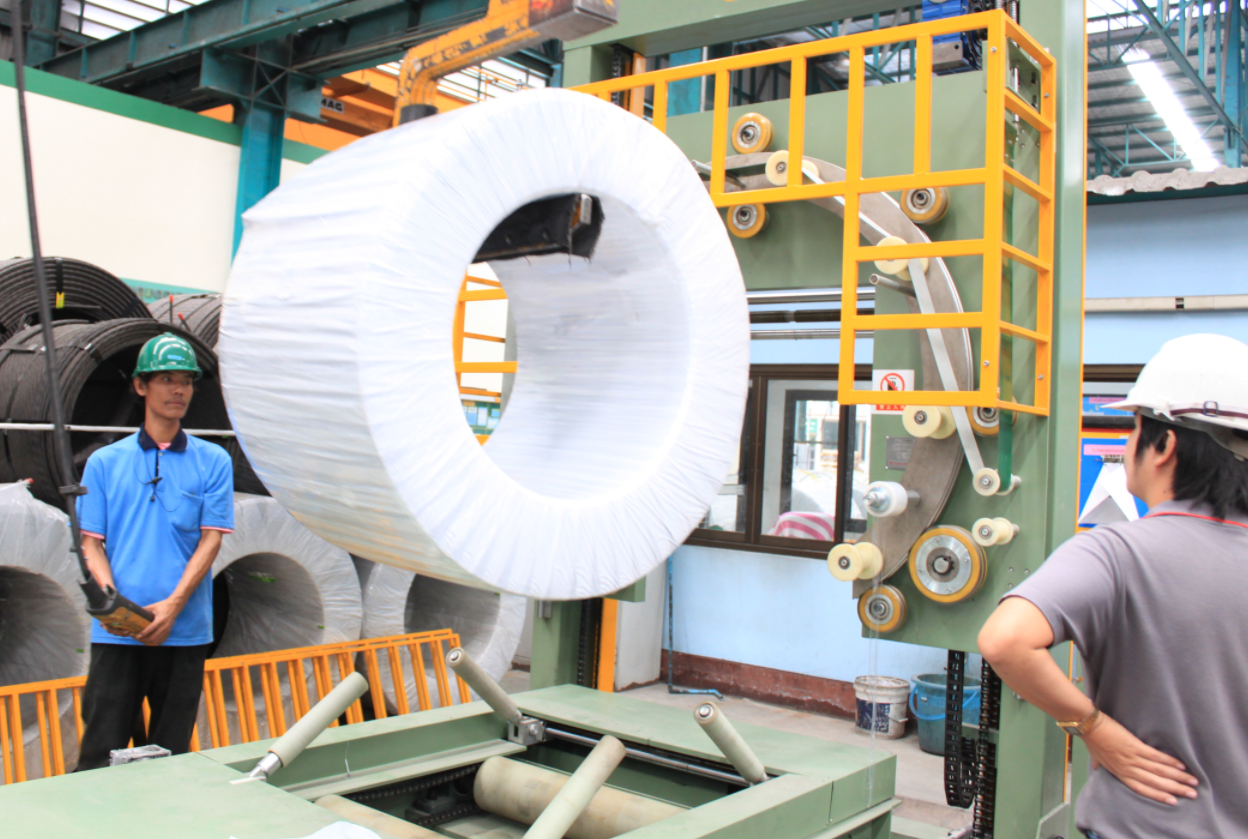

Are you struggling to keep your vintage coil wrapping machine running smoothly without breaking the bank? This guide provides information on finding cost-effective replacement parts, including used components, affordable spare parts, and solutions for vintage packaging repairs.

Maintaining and repairing older coil packing machines presents unique challenges. Sourcing original parts can be difficult and expensive, especially for vintage models. However, with a strategic approach, you can find budget-friendly solutions to keep your machinery operational and efficient. This article explores various options for acquiring cost-effective replacement parts, focusing on used coil wrapping machine parts, budget spare components, and repair strategies for vintage packaging equipment.

Understanding the Need for Replacement Parts

Coil wrapping machines, especially older models, are subject to wear and tear. Common issues include worn-out rollers, damaged belts, malfunctioning sensors, and failing electrical components. Regular maintenance can extend the lifespan of these machines, but eventually, replacement parts become necessary.

Here’s why sourcing cost-effective replacement parts is crucial:

- Reduced Downtime: Quickly replacing faulty components minimizes downtime and maximizes production efficiency.

- Budget Management: Sourcing affordable parts helps keep maintenance costs within budget.

- Extending Machine Lifespan: Timely repairs and replacements prolong the operational life of the machinery, avoiding the need for premature replacement of the entire machine.

Exploring Used Coil Wrapping Machine Parts

One of the most budget-friendly options is to consider used coil wrapping machine parts. These parts are typically salvaged from decommissioned machines or surplus inventories.

Advantages of Used Parts: - Lower Cost: Used parts are significantly cheaper than new ones.

- Availability for Vintage Models: Many times, used parts are the only option for older, obsolete machines.

- Eco-Friendly: Reusing parts reduces waste and promotes sustainability.

Where to Find Used Parts: - Online Marketplaces: Websites like eBay often list used parts for various industrial machines.

- Surplus Equipment Dealers: Companies specializing in surplus industrial equipment may have coil wrapping machine parts.

- Machine Refurbishers: Businesses that refurbish coil wrapping machines may sell used parts they’ve removed from machines during the refurbishment process .

- Local Machine Shops: Local machine shop could have access to parts that may be cheaper for your machine.

Considerations When Buying Used Parts: - Condition: Carefully inspect the part for visible damage, wear, or corrosion.

- Compatibility: Ensure the part is compatible with your specific machine model.

- Warranty: Check if the seller offers any warranty or return policy.

- Seller Reputation: Buy from reputable sellers with positive feedback.

Budget Spare Components: Finding Affordable New Parts

When used parts aren’t an option, or when you prefer new components for critical functions, consider budget spare components from alternative suppliers.

Strategies for Finding Affordable New Parts:

- OEM Alternatives: Research if there are non-OEM (Original Equipment Manufacturer) alternatives that meet the same specifications at a lower price.

- Parts Suppliers: Many industrial parts suppliers offer a wide range of components for coil wrapping machines.

- Online Retailers: Online retailers specializing in industrial parts can offer competitive pricing due to lower overhead costs.

- Negotiate Prices: Don’t hesitate to negotiate prices with suppliers, especially when buying in bulk.

Types of Budget Spare Components: - Belts and Rollers: Standard belts and rollers can often be sourced from general industrial suppliers. Choosing generic alternatives for these parts significantly reduces costs.

- Sensors and Switches: Replacement sensors and switches are available from electronic component suppliers like digikey or mouser.

- Electrical Components: Fuses, relays, and other electrical components can be purchased from electrical supply stores at competitive prices

Vintage Packaging Repairs: Special Considerations

Repairing vintage packaging machines requires a specialized approach due to the scarcity of original parts and the unique construction of these machines.

Strategies for Vintage Packaging Repairs: - Refurbishing Existing Parts: Instead of replacing a part, consider refurbishing it. Machining, welding, and reconditioning can restore worn parts to their original functionality. Consulting with a restoration specialist is extremely important as well.

- Custom Fabrication: If a part is no longer available, consider having it custom-fabricated by a machine shop.

- Reverse Engineering: If you have a broken part, a machine shop can reverse-engineer it to create a new one based on the original dimensions and materials.

- Salvaging from Similar Machines: Search for similar machines, even if they are not coil wrappers, to find compatible parts that can be adapted.

Case Studies

- Flexi-Coil 5000 Air Drill Packer Recappers: Often, recappers are available to fully cover the wear surface and extend the life of packers on air drills.

- Old Man Emu Suspension Range: The use of coil spring seat packers to restore nominal lift height for vehicles fitted with bull bars and winches.

- Land Rover Discovery Coil Spring Spacers: These are often readily available so you can find coil spring spacers for older Land Rover Discovery models.

The Importance of Preventative Maintenance

Preventative maintenance is critical to minimizing the need for replacement parts. Regularly inspecting and servicing your coil wrapping machine keeps it running smoothly and identifies potential issues before they turn into major problems.

Preventative Maintenance Tips: - Regular Cleaning: Clean the machine regularly to remove dust, debris, and lubricant buildup.

- Lubrication: Lubricate moving parts per the manufacturer’s recommendations.

- Inspection: Inspect belts, rollers, and other components for wear and tear during regular maintenance.

- Calibration: Calibrate sensors and other measuring devices regularly.

- Training: Properly train operators on correct machine operation and maintenance procedures.

Finding cost-effective replacement parts for older coil packers is essential for operational efficiency and budget control. By considering used components, budget spare parts, and repair strategies, you can keep your vintage machines running smoothly. Prioritize preventative maintenance to minimize the need for frequent replacements.

Where to Find Parts: Comparative Chart

| Part Type | New | Used | Refurbished/Fabricated |

|---|---|---|---|

| Belts & Rollers | Industrial Parts Suppliers, Online Retailers | Surplus Dealers, Online Marketplaces (eBay) | Local Machine Shops, Speciality Restoration Shops |

| Sensors & Switches | OEM Suppliers, Electronics Suppliers | Surplus Dealers, Online Marketplaces (eBay) | N/A (Replacement Typically Preferred) |

| Electrical Components | Electrical Supply Stores, Online Retailers | Surplus Dealers, Online Marketplaces (eBay) | N/A (Replacement Typically Preferred) |

| Machine-Specific Components (Gears etc.) | OEM Suppliers, Custom Manufacturers | Surplus Dealers, Online Marketplaces (eBay), Companies decommissioning similar machines | Local Machine Shops (For fabrication or repair), Specialty Restoration Shops |

| Packers / Recappers | Air drill specialized companies/suppliers | From companies decommissioning similar machines, Online Marketplaces (eBay) (check dimensions!) | local machine shops or specialized packer recapping services (check condition.) |

| Complete suspension range (Used for Packing) | OEM Suppliers and aftermarket suppliers | From companies decommissioning similar machines, Online Marketplaces (eBay) (check dimensions!) | local machine shops or specialized packer recapping and refurbishment services (check condition.) |

| Coil Spring Spacers | Aftermarket suppliers and specialized website | Online Marketplaces (eBay) | Can be custom fabricated if necessary |

Conclusion

Keeping your vintage coil wrapping machine operational doesn’t have to be a financial burden. By exploring used parts, budget components, and specialized repair solutions, you can maintain your machinery cost-effectively. Remember to prioritize preventative maintenance and always ensure the compatibility and quality of replacement parts. Doing so will extend the lifespan of your equipment, reduce downtime, and keep your production running smoothly.