The Comprehensive Guide to the Wire Coil Packing Line

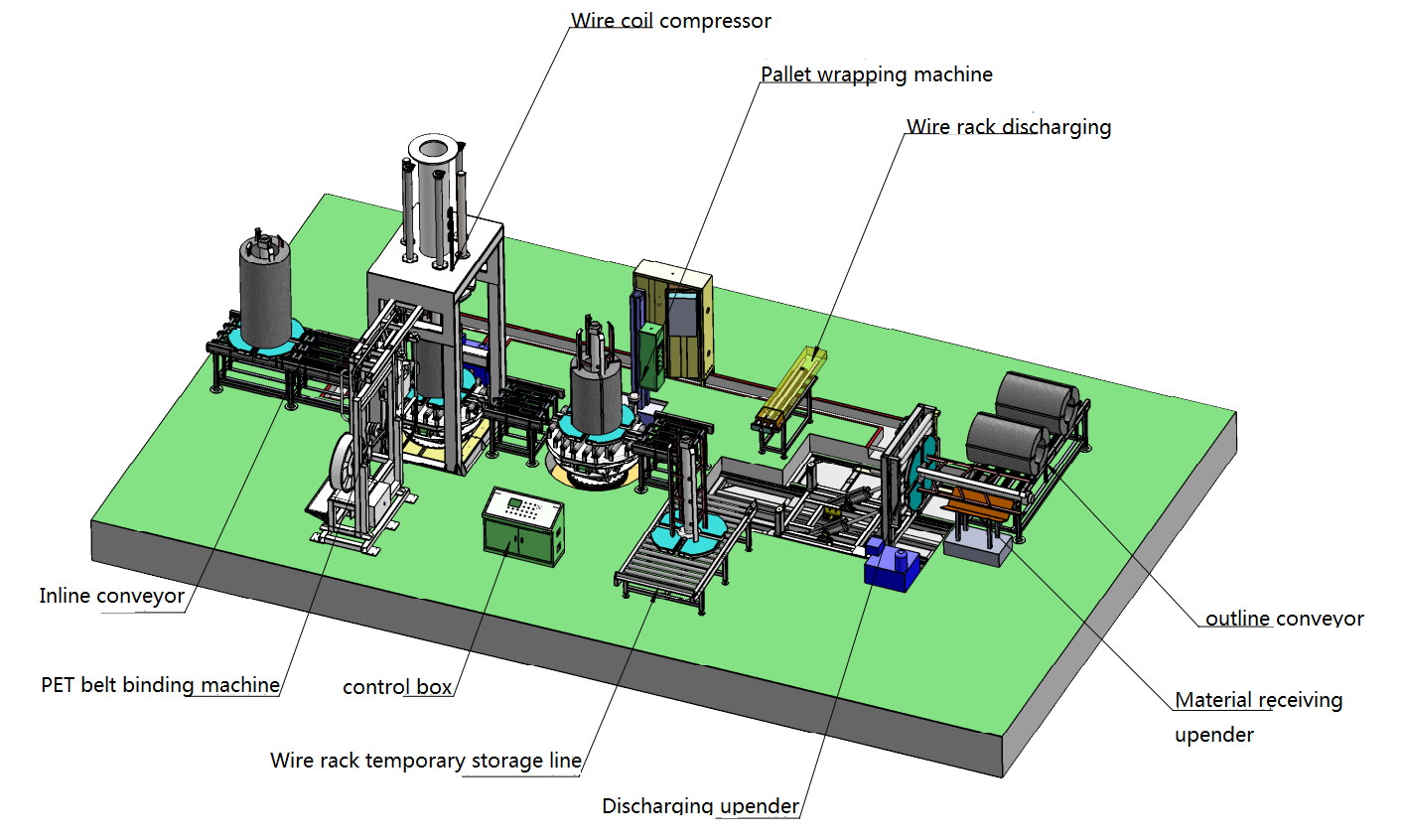

FHOPE provide automatic wire packing line that includes the wire coil compactor and strapping machine for automatic handling the wire coil with basket online.The wier coil packign line includes the automatic Strapping Machine that performs all the straps in different strapping positions. The wire coil along with the basket should be stay in table and the compactor system will compacting the wire coil on spool.The wire coil along with the basket should be stay in table and the compactor system will compacting the wire coil on spool. It is al solution adjustable to accommodate materials by inverters. It is the most efficiency equipment for improving your wire coil packagingwhich meets the handling and stacking requirement for higher packaging efficiency with minimal space and saving labor cost in wire handling.

The operator should place a basket along with its wire coil on the conveyor and conveyor move the coil into compacting station. It's an automatic solution for connecting compressing with drawing machine to handling the basket. It makes the basket gathering the wire coil. This automatic line has the capacity to increase your production dramatically and decrease the labour costs.

Automatic Wire Coiling Machine:

The automatic wire coiling machine is responsible for precisely coiling the wire into uniform shapes and sizes. It allows for adjustable coil dimensions in OD, ID, width, ensuring consistency and minimizing manual intervention. This machine sets the foundation for efficient packaging by creating neatly coiled wires ready for the next steps.

Automatic Wire Coiling Machine

The automatic wire coiling machine is responsible for precisely coiling the wire into uniform shapes and sizes. It allows for adjustable coil dimensions in OD, ID, width, ensuring consistency and minimizing manual intervention. This machine sets the foundation for efficient packaging by creating neatly coiled wires ready for the next steps.

Wire Compacting and Strapping Machine

This machine compacts the wire coil in the bastkt, making it denser and more stable. Once compacted, the machine straps the coil with durable materials, such as steel or PET straps, to hold it firmly in place. This step is crucial in preventing coil deformation and ensuring that the coil retains its shape during handling and transportation.

Wire Coil Strapping Machine

The wire coil strapping machine adds an extra layer of security by applying additional straps around the coil by PET or steel belt.. It uses tension control to ensure that the straps are tight enough to secure the wire without causing damage. This machine enhances the stability of the wire coil, especially for heavier coils that require additional support.

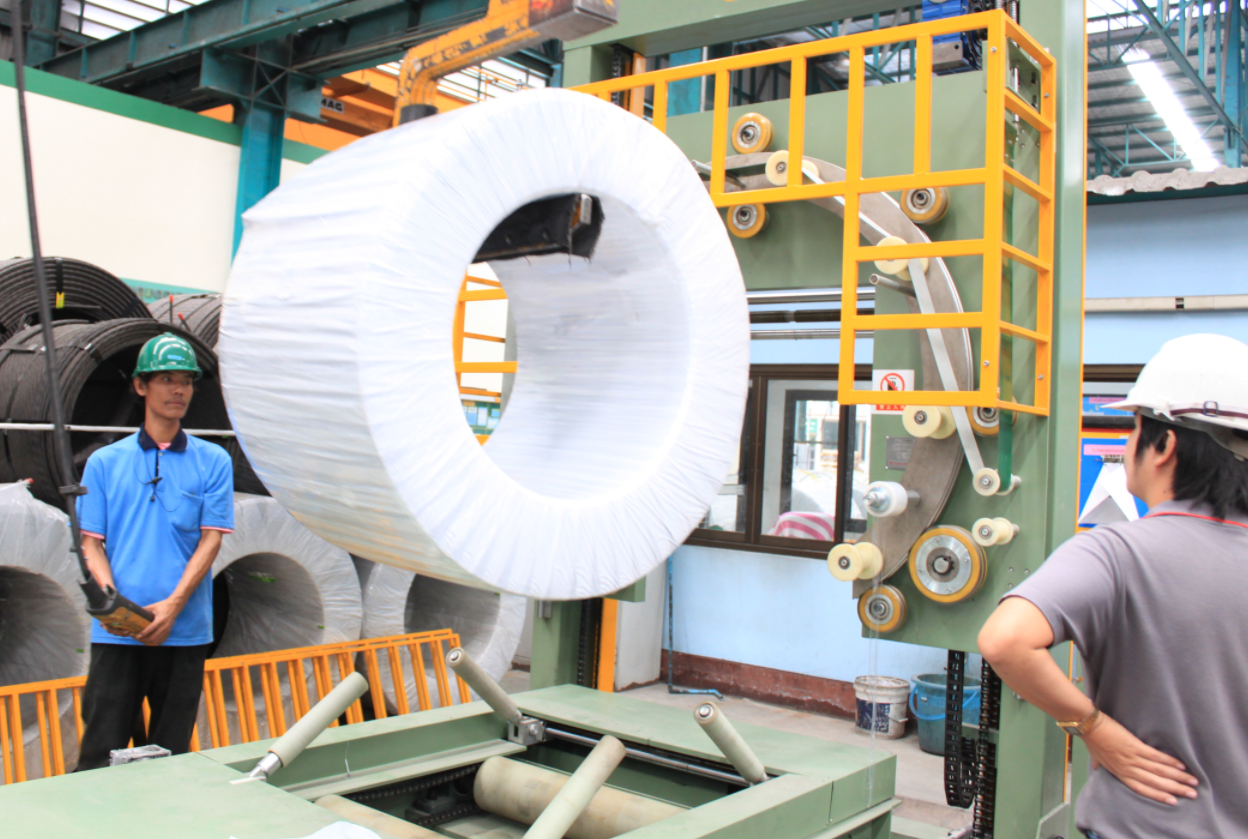

Wire Coil Wrapping Machine

The wire coil wrapping machine is designed to wrap the coil with protective materials such as stretch film, woven fabric, or paper. This wrapping provides a protective layer against environmental factors like moisture, dust, and physical damage. The machine can be customized to apply single or multiple layers of wrapping, depending on the protection required.

Automatic Wire Packing Line

-

Automatic wire rod compacting and strapping machineAutomatic wire rod compacting, strapping, and packing machine is an advanced solution designed for wire rod coil packaging. This machine is suitable for wire rod coils with an OD of 100-200mm, width of 1000-3000mm and weight up to 2T. With 4 strapping heads, the strapping speed can reach 60 seconds per coil, streamlining the pack...

-

Automatic steel wire coil compactor and strapping machineOur compacting machine is a comprehensive solution designed to compact wire coils and strap them using a manual tool. This machine features frames, an electric cabinet, and a hydraulic installation, providing businesses with a reliable and efficient solution for their compacting and strapping needs. The manually operated strappin...

-

Automatic wire coil compressing and strapping packing lineThis is a automatic solution for connecting compressing with drawing machine to handling the basket. It makes the basket gathering the wire coil. The wire coil along with the basket should be stay in table and the compactor system will compacting the wire coil on spool. It is al solution adjustable to accommodate materials by inv...

-

Automatic wire coil compressing packing lineThe Automatic Strapping Machine performs all the straps in different strapping positions. The wire coil along with the basket should be stay in table and the compactor system will compacting the wire coil on spool. It is al solution adjustable to accommodate materials by inverters.The offered line is designed for the handling of ...

-

Automatic wire coil compacting and strapping solutionFhope provides semiauto and automatic wire coil compacting and strap packaging solution. Fhope has accumulated the rich experience in provide customized designing and manufacturering automatic wire compressor packaging equipment for wire coils; There are different solution to compacting and strapping of wire coils of any size, st...

What Are the Benefits of a Wire Coil Packing Line?

- Increased Efficiency: Automation of coiling, strapping, wrapping, and palletizing speeds up production, reduces labor costs, and enhances productivity for various coil specifications.

- Enhanced Safety:Automation minimizes manual handling, reducing the risk of worker injuries and ensuring safer operations.

- Consistent Quality: Automated machinery delivers uniform packaging that meets industry standards, improving the integrity and appearance of the coil surface.

- Reduced Material Waste: Precise control during packaging processes optimizes material use and reduces waste.

- Improved Product Protection: Secure strapping and wrapping protect wire coils during transport and storage, minimizing product loss.

- Integrated System Management:

How to Choose the Proper Wire Coil Packing Line?

- Assess Production Requirements:Consider the size, weight, and type of wire coils you produce. Ensure the packing line you choose can handle your specific coil dimensions and production volume.

- Automation Level:Determine the level of automation you need. Fully automated lines offer maximum efficiency, while semi-automated lines might be more suitable for smaller-scale operations.

- Customization Needs:PLook for a packing line that can be customized to suit your specific requirements, such as different strapping materials, wrapping types, and coil sizes.

- Budget and ROI:Evaluate your budget and the expected return on investment (ROI). A higher initial investment in a fully automated line can lead to long-term savings in labor and material costs.

Why Choose FHOPE for Your Wire Coil Packing Line?

- Advanced Technology: FHOPE offers state-of-the-art machinery equipped with advanced features like adjustable coiling dimensions, automatic strapping tension control, and multi-layer wrapping capabilities.

- Customization: FHOPE provides tailored solutions to meet your specific packaging needs, ensuring that the packing line integrates seamlessly into your production process.

- Reliable Support:With FHOPE, you benefit from comprehensive support services, including installation, maintenance, and technical assistance, ensuring your packing line operates efficiently.

Frequently Asked Questions

We've compiled key FAQs about mold flippers for your convenience. If you don't find your question, call us at +8613951501635 or email info@fhopepack.com.

> How long does it take to install a wire coil packing line?

> Can the packing line handle different coil sizes?

> What materials can be used for wrapping the wire coils?

> Is the system easy to operate?

> How does the packing line improve safety?

> How to Guarantee The Quality?

> Can Products be Customized?

> What is the Return Policy?

Product Inquiry

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635