Introduction

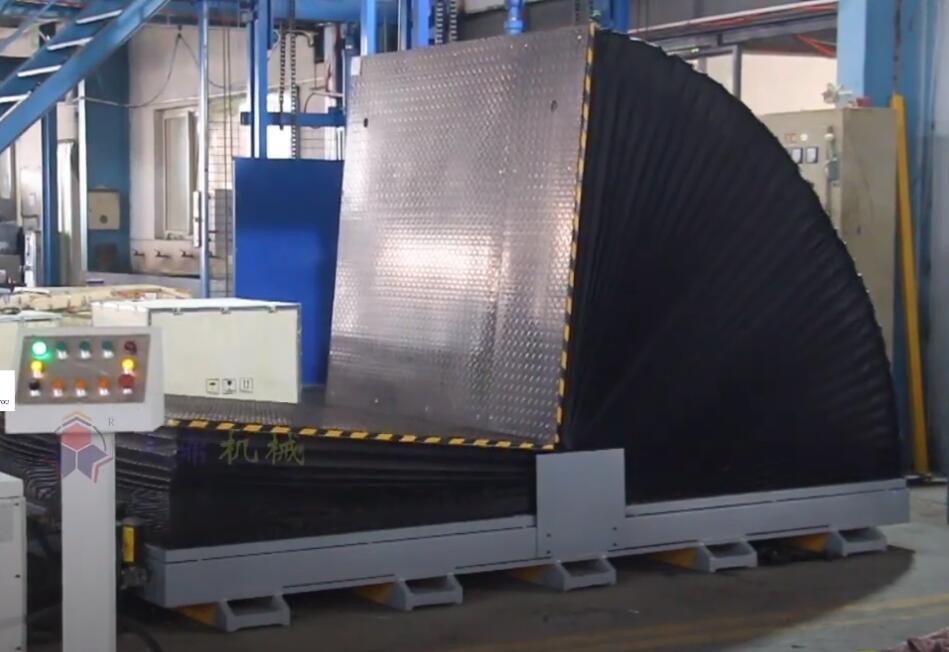

Introducing our 90-degree flipper solution, designed for efficient handling of moulds and square metal lumps. This video showcases its application in transforming heavy, irregularly-shaped items safely and effectively.

Problem-Challenge

Handling large, irregularly-shaped moulds manually is perilous and inefficient. The high value of these moulds means no risk can be taken, as improper handling could result in costly damages. Additionally, the need for special spreaders and fastening methods complicates the process, often leading to errors.

Customization for Solution

Our motorized mould flipper is tailored to accommodate various specifications. It supports mould dimensions ranging from 1000mm to 1800mm in length, width, and height, with a loading capacity of up to 50 tons. The adjustable mechanical arms ensure secure handling, adapting to different sizes and shapes to meet specific customer needs.

Key Features and Benefits

The 90-degree flipper for moulds offers:

- Efficiency and Cost Reduction: Automates the turnover process, handling 50-ton loads with ease, reducing manual labor and associated costs.

- Improved Security: Equipped with emergency stops and position sensors, operating within a noise level under 70 dB for enhanced safety and comfort.

- Reduced Material Loss: Precise handling minimizes the risk of damage to valuable moulds, thanks to its high-strength steel frame.

- Easy Integration: Seamlessly integrates into existing production lines with a PLC and touchscreen interface, offering both automatic and manual modes.

- Quality Improvement: Consistent and accurate handling enhances overall product quality, functioning efficiently in temperatures from -10°C to 50°C.

Semi-annual maintenance inspections are recommended to maintain optimal performance.

Contact Us Now

Ready to revolutionize your mould handling process? Contact us for a custom quote or schedule a demo. Explore detailed product specifications and discover how our solution can meet your specific needs.

FAQs

1. Can the flipper handle different mould sizes?

Yes, the flipper’s mechanical arms adjust to accommodate moulds with dimensions from 1000mm to 1800mm.

2. What safety features are included?

The system includes emergency stops and position sensors to ensure safe operation.

3. How does the system integrate into existing production lines?

The flipper is designed for easy integration, working seamlessly with your current setup to improve workflow and efficiency.

For more information, contact us today and transform your mould handling with our advanced flipper solution.