Automatic Pipe Coiling and Strapping Machines

2024 Automation Trends and Developments in Automatic Pipe Coiling and Strapping Machines

Introduction

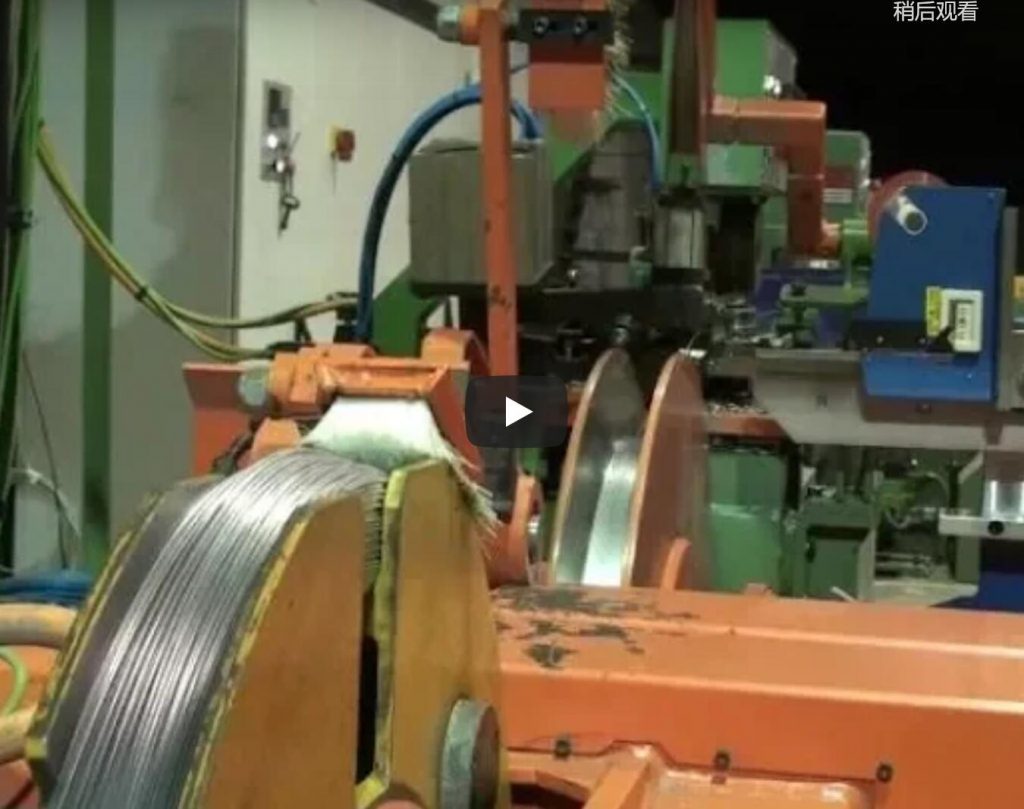

As we move into 2024, automation in industrial machinery continues to advance at an incredible pace. Among the key areas benefiting from these developments are automatic pipe coiling and strapping machines, which have become essential in industries such as plumbing, construction, and manufacturing. These machines streamline the bundling and packaging of pipes, significantly enhancing productivity while reducing labor costs. In this article, we will explore the latest trends and technological developments shaping this industry in 2024, highlighting how businesses can benefit from adopting cutting-edge automation solutions.

The Growing Demand for Automation

Automation in the pipe coiling and strapping sector is being driven by several factors, including the increasing need for efficiency, higher quality control standards, and labor shortages in key manufacturing industries. As companies look to optimize their production lines, automated systems that handle complex tasks like coiling and strapping with minimal human intervention have become indispensable.

One of the key trends in 2024 is the push for fully automated solutions that not only improve speed but also deliver consistent, repeatable results. With these advancements, businesses can achieve higher throughput, reduce human error, and lower operational costs, all while maintaining superior product quality.

Trend 1: AI-Driven Precision

One of the most exciting trends in automatic pipe coiling and strapping machines is the integration of artificial intelligence (AI). AI algorithms can now analyze and adjust various parameters during the coiling and strapping process to ensure precision. For example, sensors embedded in these machines collect data on the tension, diameter, and alignment of the pipes, feeding this information back into the AI system to make real-time adjustments.

By using AI-driven precision, manufacturers can ensure that every coil or strap is applied with optimal tightness and alignment, reducing the risk of product damage during transportation. This leads to improved product durability and customer satisfaction.

Trend 2: Enhanced Robotics for Flexibility

Robotic systems are being incorporated into automatic coiling and strapping machines to allow for greater flexibility. In the past, these machines were often designed to handle a limited range of pipe sizes and materials, which constrained their versatility. However, modern robotic arms and manipulators now enable machines to adapt quickly to different product specifications without the need for manual adjustments.

In 2024, multi-purpose robotic systems will allow manufacturers to handle a wider variety of pipes, whether they are PVC, metal, or plastic, and automatically switch between different coiling or strapping techniques. This flexibility will be a game-changer for businesses that need to process multiple product types in quick succession.

Trend 3: IoT Integration for Real-Time Monitoring

The Internet of Things (IoT) is making its mark on nearly every aspect of industrial automation, and automatic pipe coiling and strapping machines are no exception. By embedding IoT sensors and connectivity features into these machines, manufacturers can now monitor their equipment in real time. This allows for proactive maintenance, early detection of faults, and instant adjustments based on live data.

IoT-enabled machines also provide businesses with valuable insights into their production metrics, including cycle times, downtime, and energy consumption. With this data, companies can optimize their operations, ensuring that their machines are always running at peak efficiency.

Trend 4: Energy Efficiency and Sustainability

Sustainability is a major focus for industries across the globe, and 2024 is no different. With rising energy costs and increasing environmental concerns, manufacturers are seeking energy-efficient solutions that minimize their carbon footprint. Automatic pipe coiling and strapping machines are now being designed with energy-saving technologies, such as regenerative braking and energy-efficient motors.

Additionally, some machines are equipped with smart energy management systems that monitor and control power usage, ensuring that the machines only consume energy when necessary. These developments not only reduce operational costs but also help companies meet their sustainability goals.

Trend 5: Advanced Safety Features

Safety is always a top priority in industrial settings, and the latest advancements in automatic pipe coiling and strapping machines include enhanced safety features designed to protect operators and prevent accidents. In 2024, machines are being equipped with advanced sensors and safety protocols that automatically stop the machine if a hazard is detected.

For example, some systems use laser sensors to detect any foreign objects in the machine’s operating area, instantly halting operations to prevent damage or injury. Additionally, remote monitoring and control systems allow operators to oversee the machine’s functioning from a safe distance, reducing the risk of accidents during operation.

Trend 6: Customization and Modular Design

Another significant trend in 2024 is the move toward customizable and modular machine designs. Manufacturers are increasingly demanding machines that can be tailored to their specific production needs. Whether it’s adjusting for different pipe diameters, lengths, or materials, companies are looking for systems that can easily be modified to suit various production requirements.

Modular designs are also becoming more popular, allowing businesses to add or remove components based on their current needs. For example, a modular machine might allow a company to start with a basic coiling system and later add advanced strapping modules as their production volume increases.

Trend 7: Increased Automation in Post-Production Handling

In addition to automating the coiling and strapping process, manufacturers are now turning their attention to post-production automation. Automated systems can handle the packaging, labeling, and even transportation of coiled pipes, reducing the need for human intervention at every stage of the production process. In 2024, we’re seeing more integration of robotic handling systems that can manage the entire workflow from coiling to final shipment.

This end-to-end automation allows manufacturers to streamline their operations and ensure consistency in product handling. It also frees up labor resources for higher-value tasks, further improving overall efficiency.

Conclusion

The automation trends and developments in automatic pipe coiling and strapping machines for 2024 offer businesses the opportunity to optimize their production processes in unprecedented ways. With AI-driven precision, IoT integration, enhanced robotics, and energy-efficient designs, these machines are transforming how industries operate. By adopting these cutting-edge technologies, companies can stay ahead of the competition, reduce operational costs, and improve both safety and sustainability.

As we move forward, it’s clear that automation in pipe coiling and strapping will continue to evolve, offering even more sophisticated solutions to meet the demands of modern manufacturing. Whether you’re upgrading existing systems or investing in new equipment, keeping an eye on these trends will be crucial for staying competitive in the ever-changing industrial landscape.