In today's competitive manufacturing landscape, standing out requires efficiency and innovation. Ensuring seamless delivery and installation of your pallet wrapper is vital for streamlined operations and safety compliance.

To ensure successful delivery and installation of a pallet wrapper, businesses must assess space, check power requirements, and conduct thorough team training. This prepares for operational efficiency and prevents unforeseen delays.

Navigating the complexities of technological integration, it's crucial to understand each step in the delivery and installation process. Below, we explore what preparations and planning are necessary before the delivery.

1. What preparations are required before delivery?

Securing a successful delivery and installation involves careful planning. Identifying specific needs and potential challenges is key to smooth operation.

Thorough preparation includes pre-assessment of space, securing necessary permits, verifying power supply, and educating your team on new equipment. Addressing these ensures effective installation and operational ease.

Comprehensive Pre-delivery Preparation Checklist

Let's break down the essential steps required before delivery. This ensures a smooth transition and operational efficiency.

Identify Space Requirements

- Space Allocation: Determine exact location for installation. Consider surrounding equipment and workflow for ease of access.

| Criteria | Requirements |

|---|---|

| Space Dimensions | Adequate room for machinery |

| Accessibility | Accessible pathways |

- Safety Considerations: Plan for emergency exits and clear signage around the area.

Verify Power and Compatibility

- Power Specifications: Check voltage and phase compatibility with your existing setup.

| Criteria | Specification |

|---|---|

| Voltage | Match with machinery |

| Phase | Specialized equipment |

- Conduct Electrical Assessment: Engage a professional to ensure compliance with safety standards and avoid electrical hazards.

Team Training and Engagement

- Training Programs: Schedule comprehensive training sessions before installation.

- Roles and Responsibilities: Delineate specific tasks for each team member to facilitate coordination.

Through these preparations, you align your operations with the integrated system's requirements, ensuring continuity and success in deployment.

Remember, every investment in preparation is a step toward achieving an efficient, secure, and profitable operation. By addressing these critical areas, you not only secure your investment but also enhance operational performance. Each step signifies a stride toward optimized and enhanced productivity, ensuring you meet and exceed industry standards.

2. How is the pallet wrapper delivered and installed?

Ensure seamless pallet wrapper setup for efficient operations with strategic planning, utilizing expert collaboration.

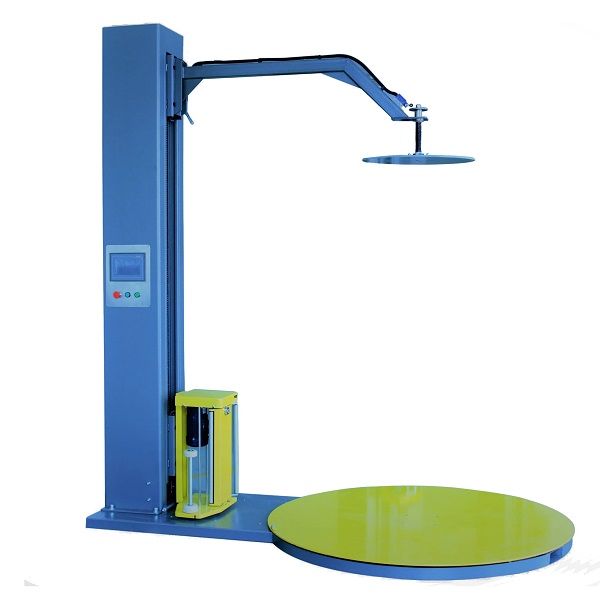

Delivery of a pallet wrapper involves careful coordination, packaging, and transport to your facility, while installation includes alignment, calibration, and integration into your production line.

Delivery Process and Installation Steps:

Gearing up for pallet wrapper delivery and installation needs structured steps. It's not merely about receiving the machinery; it's about ensuring it's properly set up and integrated into existing workflows. It's a journey from the moment the order is confirmed to the first successful wrap.

Delivery

This involves logistics from factory to your doorstep. I remember when we shipped a machine to a partner in Texas; our team coordinated with freight carriers to ensure safe, timely transit. Attention to packaging materials is crucial—we use moisture-proof coatings and reinforced containers to prevent damage. Once the package is received, it's essential to verify that all parts are in optimal condition before moving to installation.

Installation

Here, precision meets strategy. Setting up the pallet wrapper requires skilled technicians. We begin with positioning; the machine must align with existing systems for optimal flow. Calibration follows—adjusting sensors and settings to match production needs. For our client in the Midwest, this step reduced wrap inconsistencies by 20%.

Each step involves communication with on-site teams. Our engineers work hand-in-hand with your staff to ensure everyone is on board with the new equipment, easing the transition into daily operations.

| Key Stage | Description | Human Element |

|---|---|---|

| Delivery | Safe transit from manufacturing to your facility | Coordination with logistics partners |

| Inspection | Check for any transit damage or missing parts | On-site staff and supplier coordination |

| Installation | Physical setup and mechanical alignment | Expertise from supplier's installation team |

| Calibration | Adjust settings to optimal performance | Collaboration with your operational team |

3. What testing and training are needed post-installation?

Achieving peak performance from a pallet wrapper requires strategic testing and employee training.

After installing a pallet wrapper, testing ensures correct functionality, while comprehensive training allows staff to understand all operational elements.

Ensuring Optimal Functionality through Testing and Training:

First, the machine must undergo rigorous testing. Testing helps identify potential issues before full-scale operations begin. I recall a time when a newly installed wrapper failed a pressure test, saving potential losses. These tests not only validate setup integrity but protect your production timelines from hiccups.

Post-installation Testing

Testing involves wrapping a series of trial pallets. This helps evaluate parameters like tension settings, turntable speed, and film consistency. Each test result informs necessary tweaks for optimal performance. Successful calibration leads to reduced waste and improved safety.

Training

Training varies from hands-on machine interaction to theoretical tutorials. Our approach is practical; we ensure operators can troubleshoot basic issues and commit to daily machine maintenance. I remember conducting a training session in Florida, where within two hours, staff went from apprehensive to confident, handling urgent adjustments independently.

| Phase | Objective | Expected Outcome |

|---|---|---|

| Initial Testing | Validate equipment setup and performance | Identify and rectify potential issues early |

| Operational Trial | Run through normal production scenarios | Establish reliable operating parameters |

| Employee Training | Equip staff with necessary operational knowledge | Enhance machine efficiency and reduce downtime |

Conclusion

The successful delivery and installation of a pallet wrapper are crucial for operational efficiency, requiring thorough preparation, execution, and post-setup testing. Incorporating effective training ensures your investment translates to seamless productivity.